Nissan Pathfinder (2010 year). Manual - part 369

EM-80

< ON-VEHICLE REPAIR >

[VQ40DE]

CAMSHAFT

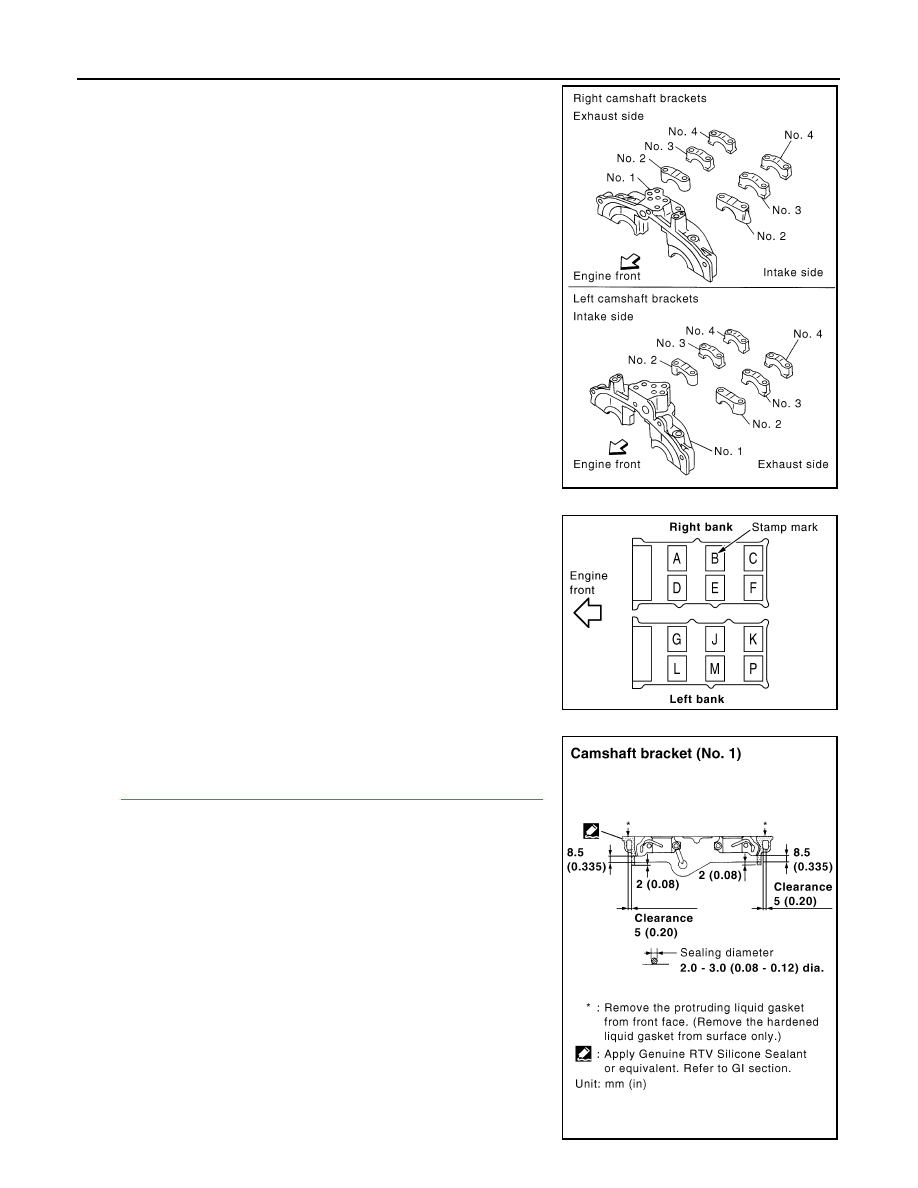

4. Install camshaft brackets.

• Remove foreign material completely from camshaft bracket

backside and from cylinder head installation face.

• Install camshaft bracket in original position and direction as

shown.

• Install camshaft brackets (No. 2 to 4) aligning the stamp marks

as shown.

NOTE:

There are no identification marks indicating left and right for

camshaft bracket (No. 1).

• Apply liquid gasket to mating surface of camshaft bracket (No.

1) as shown on right and left banks.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-14, "Recommended Chemical Products and Sealants"

.

PBIC2051E

PBIC2052E

PBIC2660E

2010 Pathfinder