Nissan Pathfinder (2010 year). Manual - part 368

EM-72

< ON-VEHICLE REPAIR >

[VQ40DE]

REAR TIMING CHAIN CASE

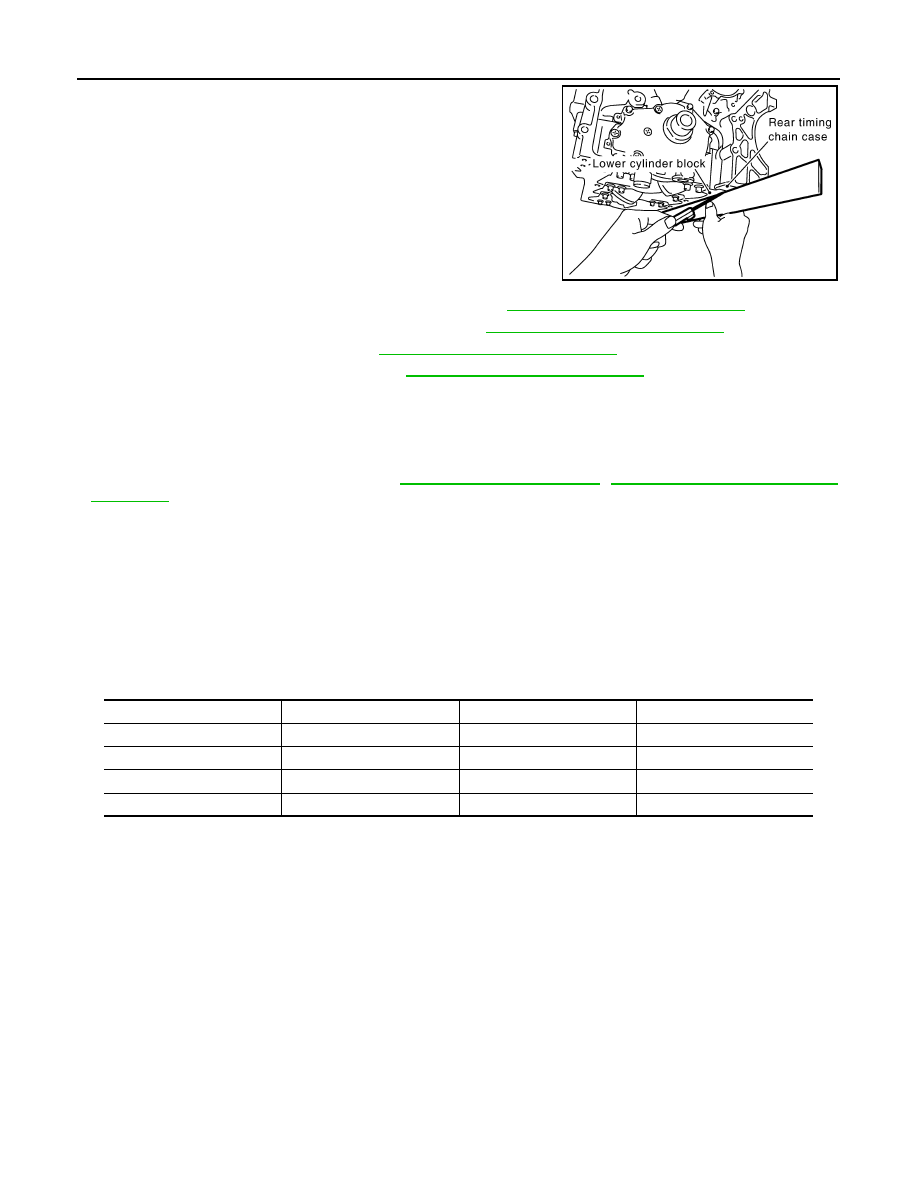

g. After installing rear timing chain case, check the surface height

difference between following parts on oil pan (upper) mounting

surface.

• If not within the standard, repeat the installation procedure.

2. Install water pump with new O-rings, if removed. Refer to

CO-22, "Removal and Installation"

.

3. Install timing chains and related components. Refer to

EM-60, "Removal and Installation"

.

4. Install front timing chain case. Refer to

EM-51, "Removal and Installation"

.

5. Install oil pan (upper) and (lower). Refer to

EM-36, "Removal and Installation"

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluid leaks, lubricant leaks and exhaust gases leaks.

• Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to

MA-17, "For Mexico: Fluids and

• Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may

generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after

hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

* Transmission fluid, power steering fluid, brake fluid, etc.

Standard

Rear timing chain case to lower cylinder block:

–0.24 to 0.14 mm (–0.0094 to 0.0055 in)

PBIC2925E

Item

Before starting engine

Engine running

After engine stopped

Engine coolant

Level

Leakage

Level

Engine oil

Level

Leakage

Level

Other oils and fluid*

Level

Leakage

Level

Fuel

Leakage

Leakage

Leakage

2010 Pathfinder