Nissan Pathfinder (2010 year). Manual - part 327

EC-708

< COMPONENT DIAGNOSIS >

[VK56DE]

P0441 EVAP CONTROL SYSTEM

P0441 EVAP CONTROL SYSTEM

System Description

INFOID:0000000005257672

NOTE:

If DTC P0441 is displayed with other DTC such as P2122, P2123, P2127, P2128 or P2138, first perform

the trouble diagnosis for other DTC.

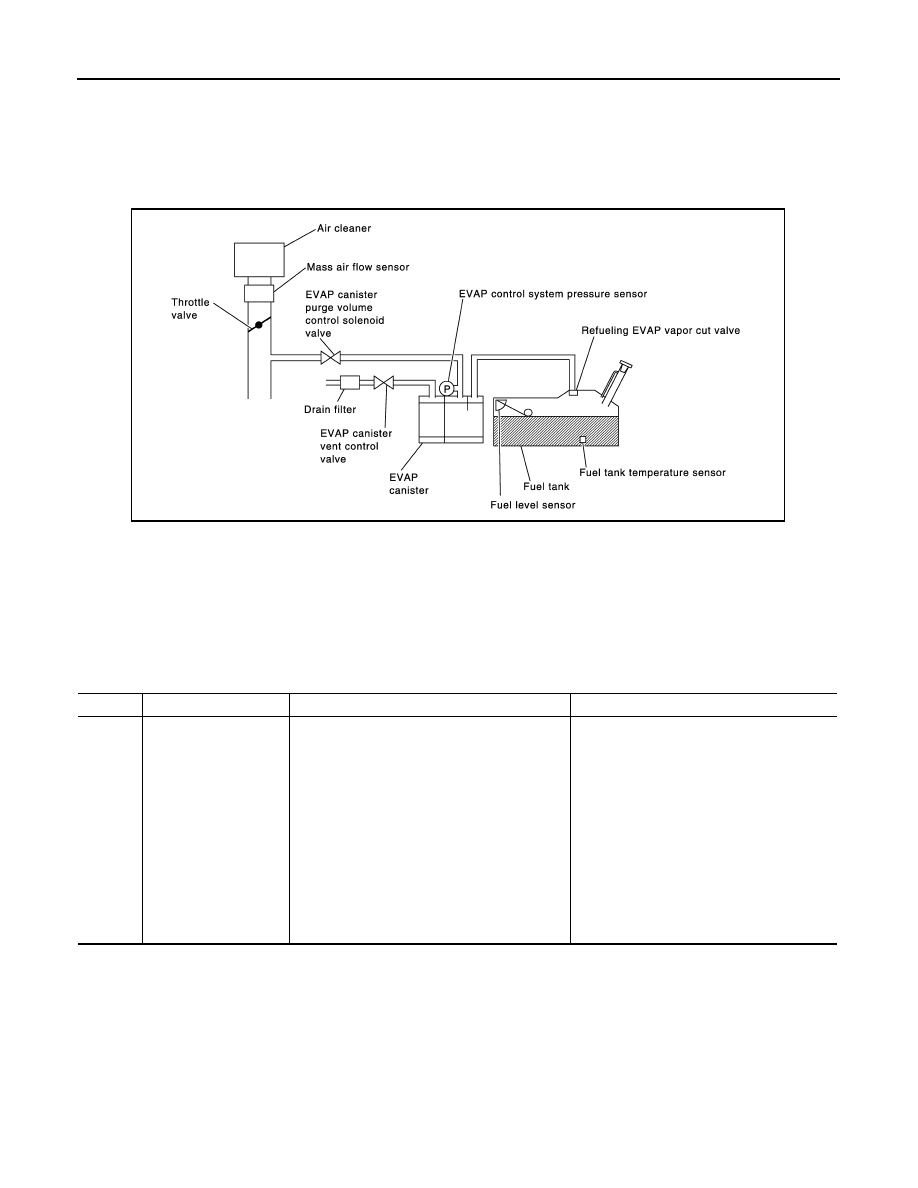

In this evaporative emission (EVAP) control system, purge flow occurs during non-closed throttle conditions.

Purge volume is related to air intake volume. Under normal purge conditions (non-closed throttle), the EVAP

canister purge volume control solenoid valve is open to admit purge flow. Purge flow exposes the EVAP con-

trol system pressure sensor to intake manifold vacuum.

On Board Diagnosis Logic

INFOID:0000000005257673

Under normal conditions (non-closed throttle), sensor output voltage indicates if pressure drop and purge flow

are adequate. If not, a malfunction is determined.

DTC Confirmation Procedure

INFOID:0000000005257674

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next step.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

PBIB3640E

DTC No. Trouble diagnosis name

DTC detecting condition

Possible cause

P0441

0441

EVAP control system in-

correct purge flow

EVAP control system does not operate properly.

EVAP control system has a leak between intake

manifold and EVAP control system pressure

sensor.

• EVAP canister purge volume control sole-

noid valve stuck closed

• EVAP control system pressure sensor and

the circuit

• Loose, disconnected or improper connec-

tion of rubber tube

• Blocked rubber tube

• Cracked EVAP canister

• EVAP canister purge volume control sole-

noid valve circuit

• Accelerator pedal position sensor

• Blocked purge port

• EVAP canister vent control valve

• Drain filter

2010 Pathfinder