Nissan Pathfinder (2010 year). Manual - part 326

EC-700

< COMPONENT DIAGNOSIS >

[VK56DE]

P0340 CMP SENSOR (PHASE)

P0340 CMP SENSOR (PHASE)

Component Description

INFOID:0000000005257663

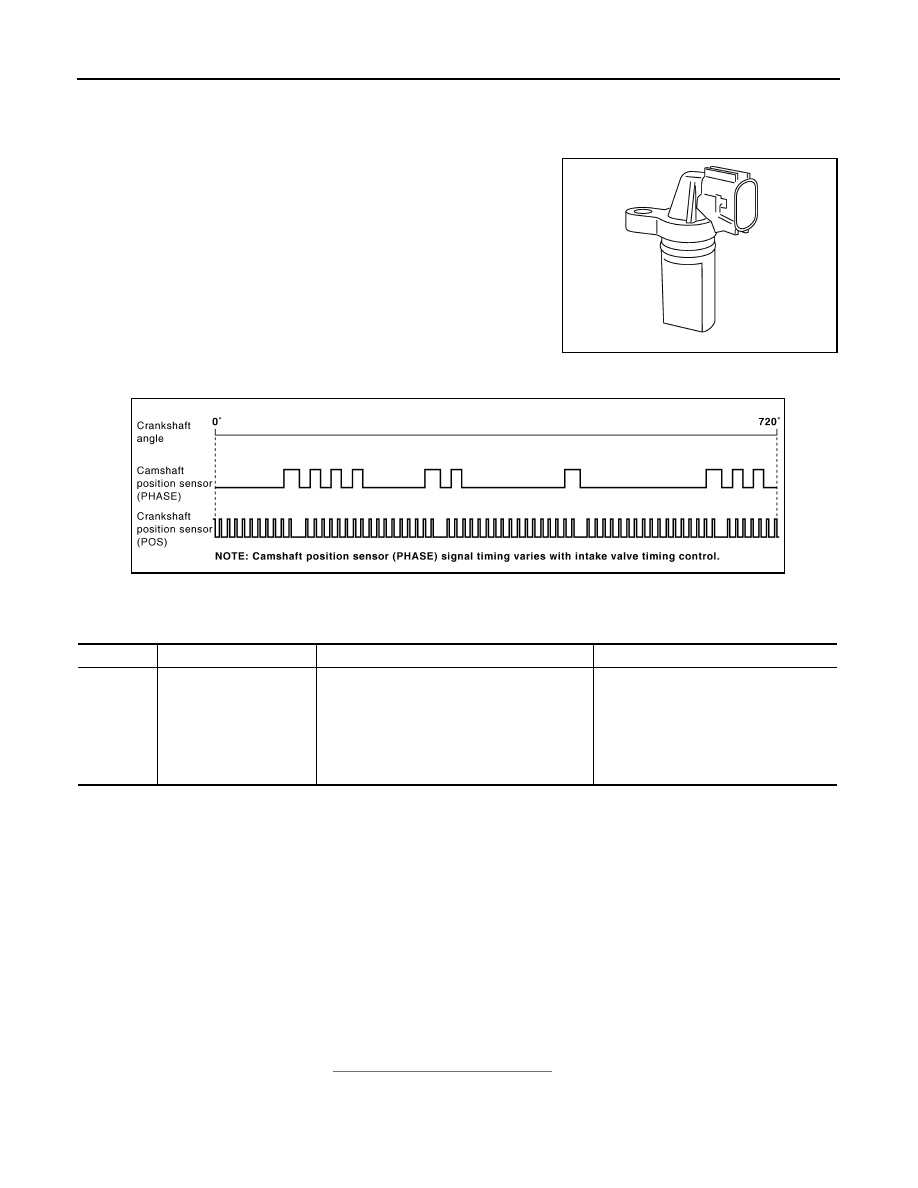

The camshaft position sensor (PHASE) senses the protrusion of

exhaust valve cam sprocket to identify a particular cylinder. The

camshaft position sensor (PHASE) senses the piston position.

When the crankshaft position sensor (POS) system becomes inoper-

ative, the camshaft position sensor (PHASE) provides various con-

trols of engine parts instead, utilizing timing of cylinder identification

signals.

The sensor consists of a permanent magnet and Hall IC.

When engine is running, the high and low parts of the teeth cause

the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor changes.

ECM receives the signals as shown in the figure.

On Board Diagnosis Logic

INFOID:0000000005257664

DTC Confirmation Procedure

INFOID:0000000005257665

NOTE:

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next step.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5 V with igni-

tion switch ON.

1. Turn ignition switch ON.

2. Crank engine for at least 2 seconds and run it for at least 5 seconds at idle speed.

3. Check 1st trip DTC.

4. If 1st trip DTC is detected, go to

If 1st trip DTC is not detected, go to next step.

5. Maintaining engine speed at more than 800 rpm for at least 5 seconds.

6. Check 1st trip DTC.

PBIB0562E

JMBIA1046GB

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0340

0340

Camshaft position sensor

(PHASE) circuit

• The cylinder No. signal is not sent to ECM for

the first few seconds during engine cranking.

• The cylinder No. signal is not sent to ECM

during engine running.

• The cylinder No. signal is not in the normal

pattern during engine running.

• Harness or connectors

(The sensor circuit is open or shorted)

• Camshaft position sensor (PHASE)

• Camshaft (Exhaust)

• Starter motor

• Starting system circuit

• Dead (Weak) battery

2010 Pathfinder