Nissan Pathfinder (2010 year). Manual - part 272

EC-268

< COMPONENT DIAGNOSIS >

[VQ40DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

5. Select “DATA MONITOR” mode with CONSULT-III.

6. Make sure that “FUEL T/TMP SE” is more than 0

°

C (32

°

F).

7. Start engine and wait at least 20 seconds.

8. Check 1st trip DTC.

9. If 1st trip DTC is detected, go to

With GST

1. Start engine and warm it up to normal operating temperature.

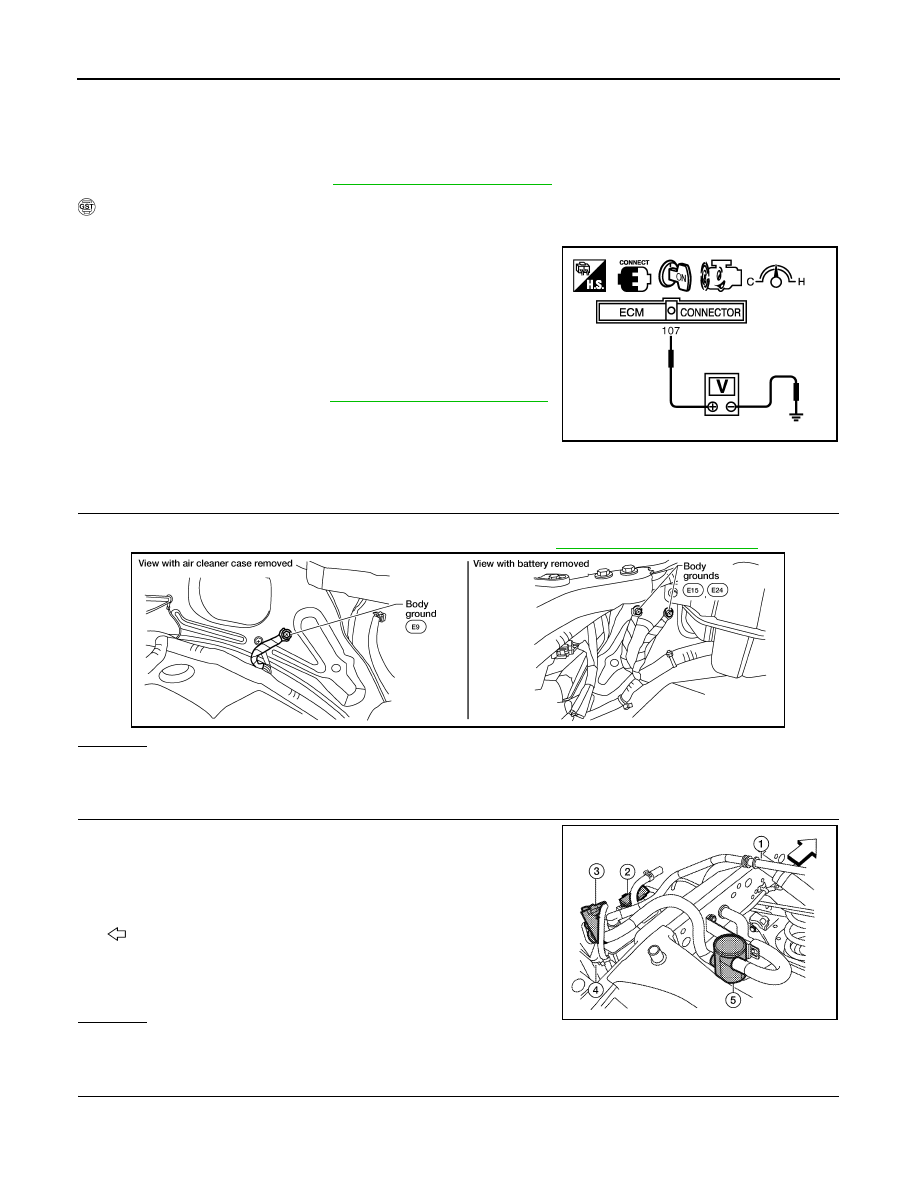

2. Check that voltage between ECM terminal 107 (Fuel tank tem-

perature sensor signal) and ground is less than 4.2V.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON.

5. Turn ignition switch OFF and wait at least 10 seconds.

6. Start engine and wait at least 20 seconds.

7. Select Service $07 with GST.

If 1st trip DTC is detected, go to

.

Diagnosis Procedure

INFOID:0000000005257253

1.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body. Refer to

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace ground connections.

2.

CHECK CONNECTOR

1. Disconnect EVAP control system pressure sensor (2) harness

connector.

-

Fuel filler pipe (top of frame view) (1)

-

EVAP canister vent control valve (3)

-

EVAP canister (4)

-

Drain filter (5)

-

: Vehicle front

2. Check sensor harness connector for water.

OK or NG

OK

>> GO TO 3.

NG

>> Repair or replace harness connector.

3.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

PBIB1110E

BBIA0539E

Water should not exist.

AWBIA0134ZZ

2010 Pathfinder