Nissan Pathfinder (2010 year). Manual - part 234

SERVICE DATA AND SPECIFICATIONS (SDS)

DLN-445

< SERVICE DATA AND SPECIFICATIONS (SDS)

[REAR FINAL DRIVE: R200]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

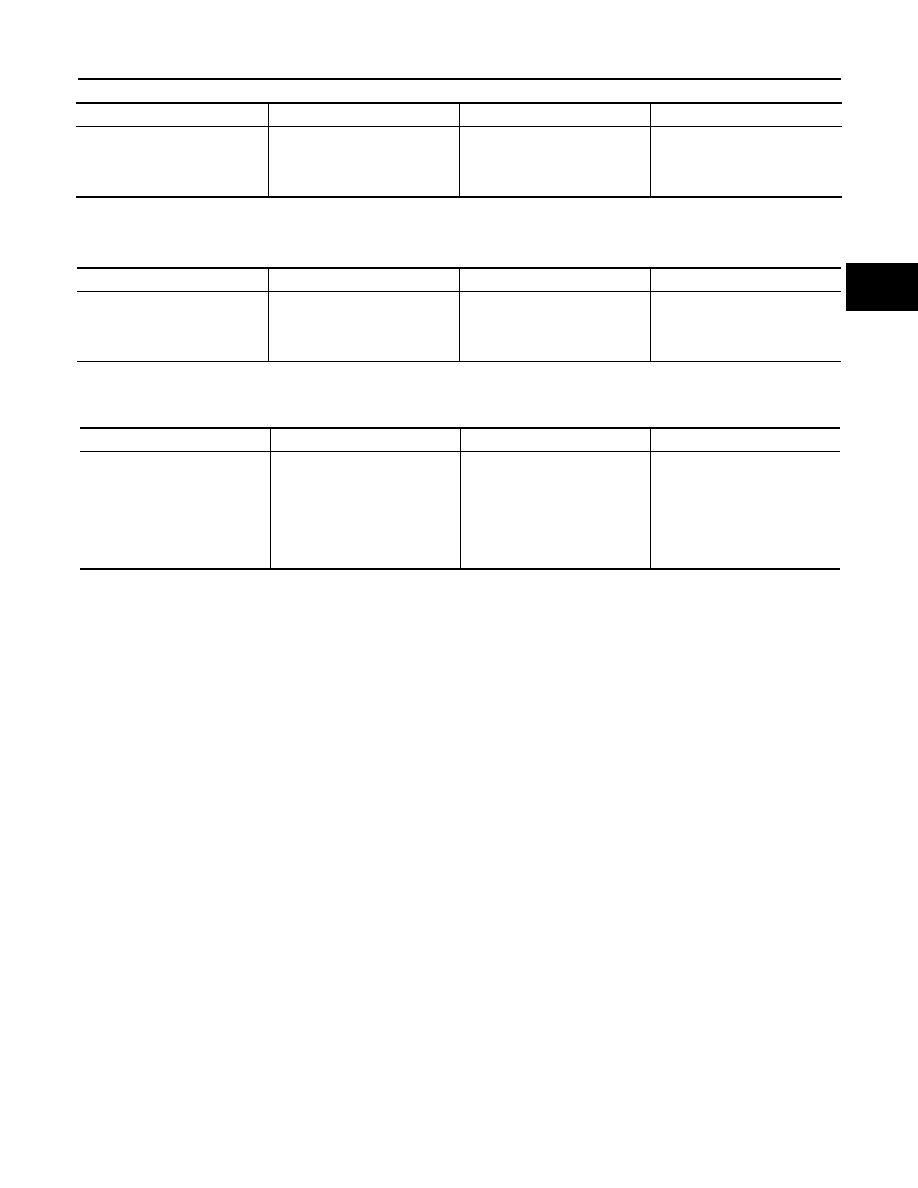

Drive Pinion Height Adjusting Washer

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Side Bearing Adjusting Washer

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Thickness Part

number*

Thickness Part

number*

0.75 (0.0295)

0.78 (0.0307)

0.81 (0.0319)

0.84 (0.0331)

38424 0C000

38424 0C001

38424 0C002

38424 0C003

0.87 (0.0343)

0.90 (0.0350)

0.93 (0.0366)

38424 0C004

38424 0C005

38424 0C006

Thickness Part

number*

Thickness Part

number*

3.05 (0.1201)

3.08 (0.1213)

3.11 (0.1224)

3.14 (0.1236)

38154 0C000

38154 0C001

38154 0C002

38154 0C003

3.17 (0.1248)

3.20 (0.1260)

3.23 (0.1272)

3.26 (0.1283)

38154 0C004

38154 0C005

38154 0C006

38154 0C007

Thickness

Part number*

Thickness

Part number*

2.00 (0.0787)

2.05 (0.0807)

2.10 (0.0827)

2.15 (0.0846)

2.20 (0.0866)

2.25 (0.0886)

2.30 (0.0906)

38453 N3100

38453 N3101

38453 N3102

38453 N3103

38453 N3104

38453 N3105

38453 N3106

2.35 (0.0925)

2.40 (0.0945)

2.45 (0.0965)

2.50 (0.0984)

2.55 (0.1004)

2.60 (0.1024)

2.65 (0.1043)

38453 N3107

38453 N3108

38453 N3109

38453 N3110

38453 N3111

38453 N3112

38453 N3113

2010 Pathfinder