Nissan Pathfinder (2010 year). Manual - part 232

REAR FINAL DRIVE

DLN-429

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R200]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

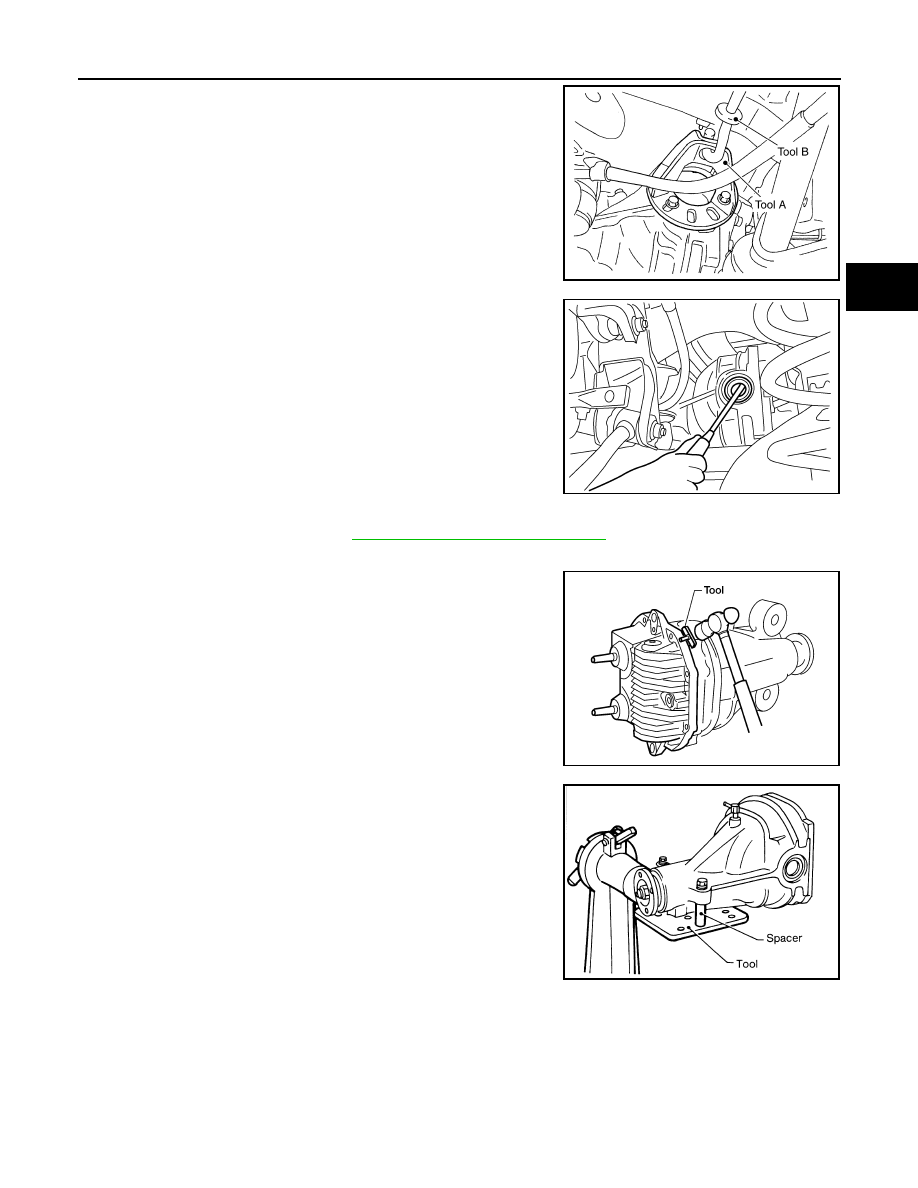

2. Remove the side flange using Tools.

NOTE:

Circular clip installation position: Rear final drive side

3. Remove the side oil seal using suitable tool.

CAUTION:

Do not to damage gear carrier.

Differential Assembly

1. Remove the side flanges. Refer to

DLN-419, "Removal and Installation"

.

2. Remove the carrier cover bolts.

3. Remove the carrier cover bolts and separate the carrier cover

from the gear carrier using Tool.

CAUTION:

• Do not damage the mating surface.

• Do not insert flat-bladed screwdriver, this will damage the

mating surface.

4. Mount the carrier on the Tool using two 45 mm (1.77 in) spacers.

Tool numbers

A: KV40104100 ( — )

B: ST36230000 (J-25840-A)

WDIA0115E

SDIA0495E

Tool number

: KV10111100 (J-37228)

WDIA0123E

Tool number

: KV38100800 (J-25604-01)

SPD888

2010 Pathfinder