Nissan Pathfinder (2010 year). Manual - part 116

BODY REPAIR

BRM-9

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

M

A

B

BRM

N

O

P

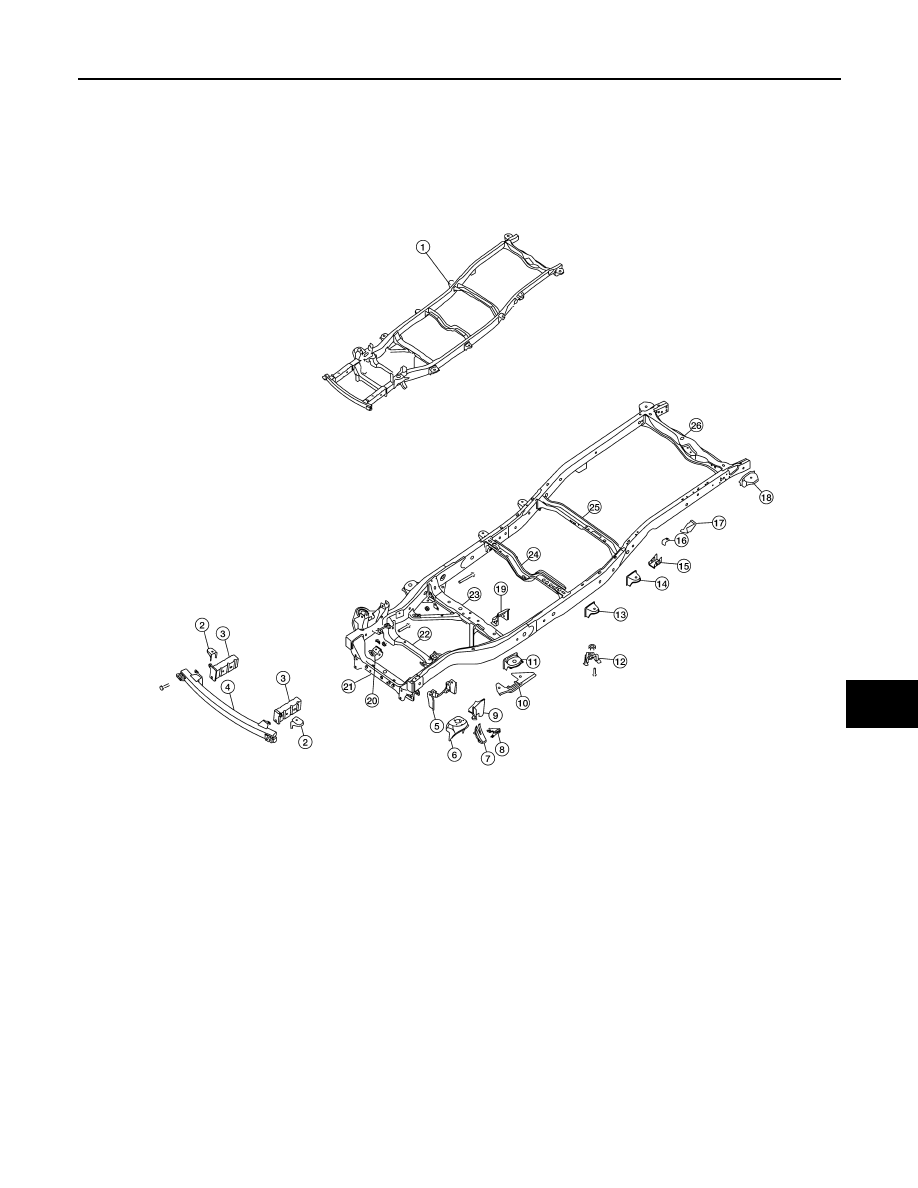

FRAME COMPONENT PARTS

1. Frame assembly

2. 1st cab mounting bracket RH/LH

3. Front side member extension assembly RH/LH

4. 1st crossmember assembly

5. Front upper link mounting bracket RH/LH

LIIA1789E

2010 Pathfinder