Nissan Pathfinder (2010 year). Manual - part 114

BRC-124

< PREPARATION >

[VDC/TCS/ABS]

PREPARATION

Commercial Service Tool

INFOID:0000000005258783

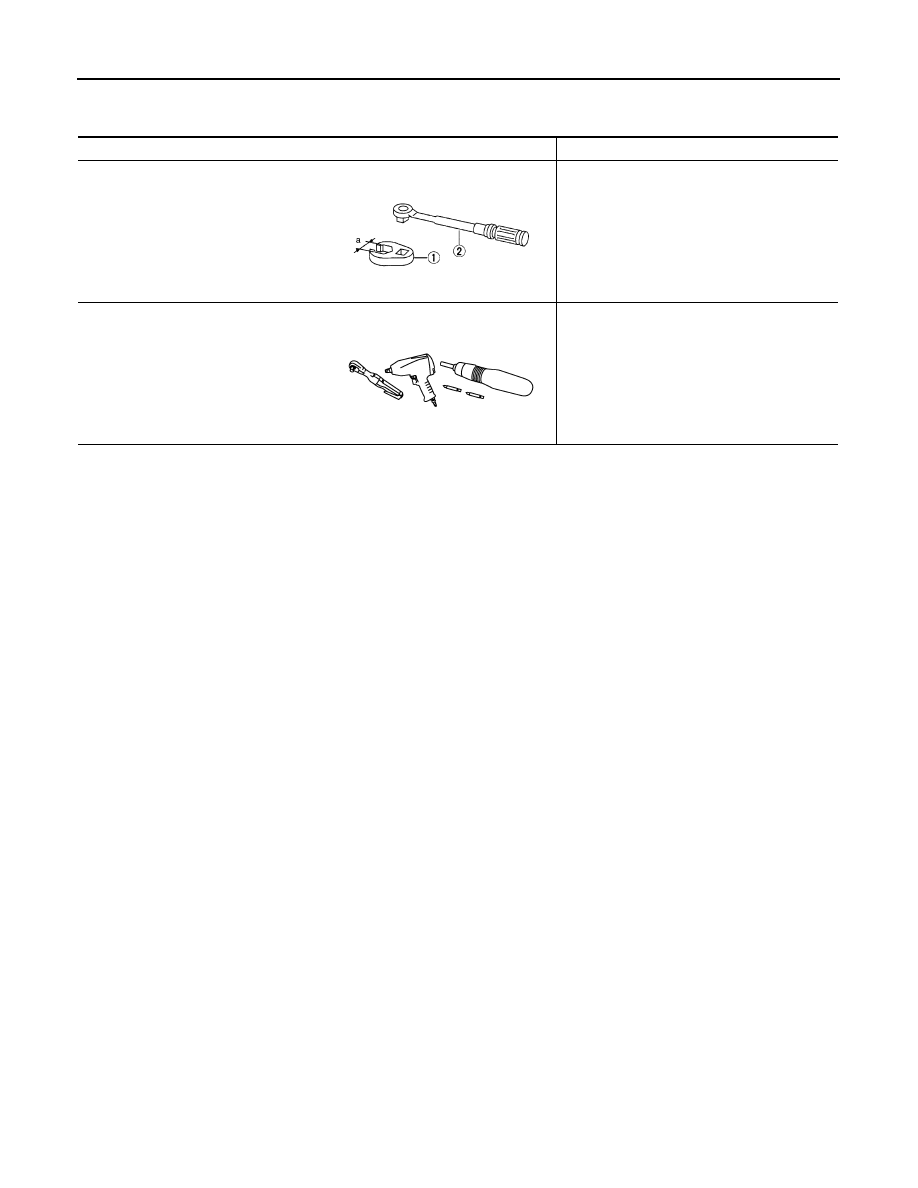

Tool name

Description

1. Flare nut crowfoot

2. Torque wrench

Removing and installing brake piping

a: 10 mm (0.39 in)/12 mm (0.47 in)

Power tool

Removing nuts, bolts and screws

S-NT360

PIIB1407E

2010 Pathfinder