Nissan Pathfinder (2007 year). Manual - part 375

AUTOMATIC DRIVE POSITIONER

SE-39

C

D

E

F

G

H

J

K

L

M

A

B

SE

2007 Pathfinder

2.

CHECK FUNCTION

With CONSULT-II

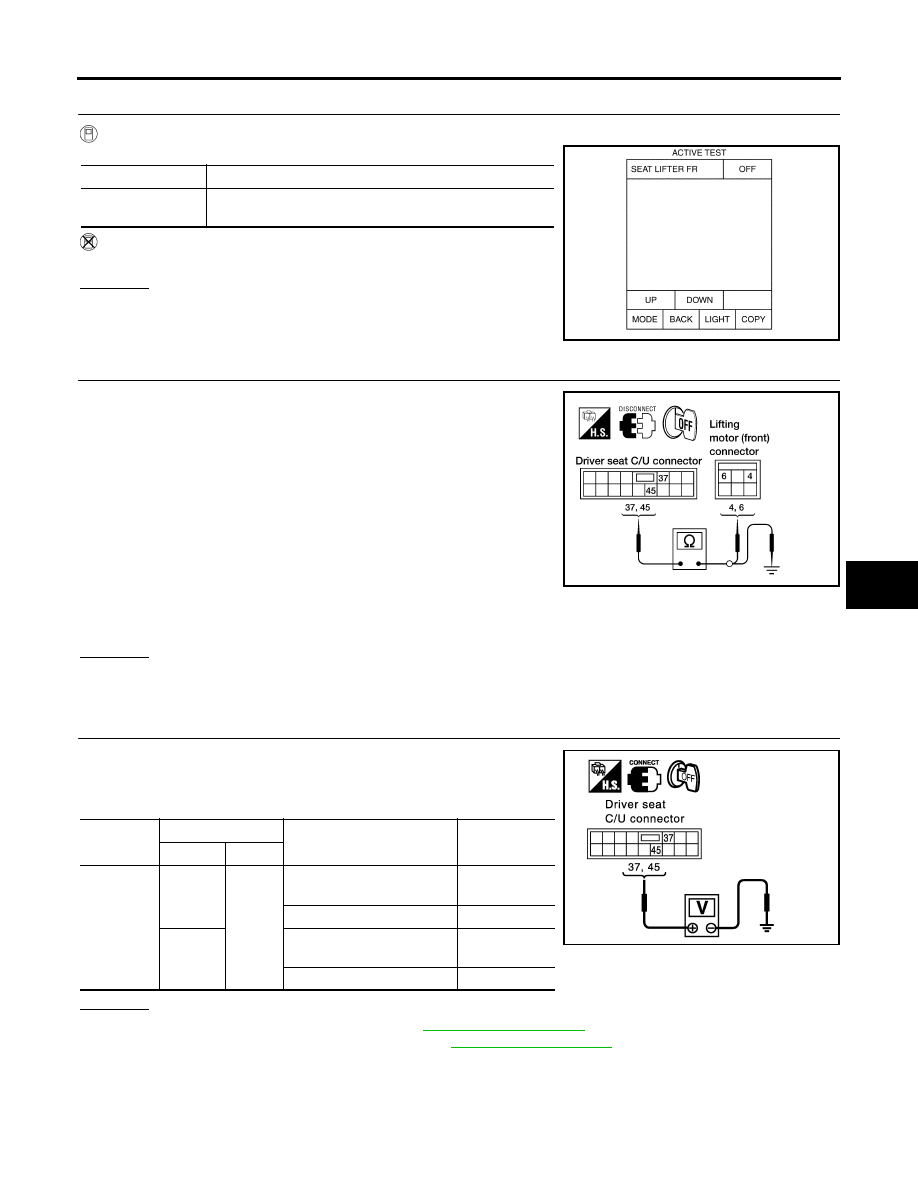

Check operation with “SEAT LIFTER FR” in ACTIVE TEST.

Without CONSULT-II

GO TO 3.

OK or NG

OK

>> Lifting motor (front) circuit is OK.

NG

>> GO TO 3.

3.

CHECK LIFTING MOTOR (FRONT) CIRCUIT HARNESS CONTINUITY

1.

Turn ignition switch OFF.

2.

Disconnect driver seat control unit and lifting motor (front).

3.

Check continuity between driver seat control unit connector P3

terminals 37, 45 and lifting motor (front) connector P6 terminals

4, 6.

4.

Check continuity between driver seat control unit connector P3

terminals 37, 45 and ground.

OK or NG

OK

>> GO TO 4.

NG

>> Repair or replace harness.

4.

CHECK DRIVER SEAT CONTROL UNIT OUTPUT SIGNAL

1.

Connect the driver seat control unit and lifting motor (front).

2.

Check voltage between driver seat control unit connector and

ground.

OK or NG

OK

>> Replace lifting motor (front). Refer to

.

NG

>> Replace driver seat control unit. Refer to

.

Test item

Description

SEAT LIFTER FR

The lifting motor (front) is activated by receiving the drive

signal.

PIIA0271E

37 - 6

: Continuity should exist.

45 - 4

: Continuity should exist.

37 - Ground

: Continuity should not exist.

45 - Ground

: Continuity should not exist.

LIIA0698E

Connector

Terminals

Condition

Voltage (V)

(Approx)

(+)

(-)

P3

37

Ground

Lifting switch (front) ON

(DOWN operation)

Battery voltage

Other than above

0

45

Llifting switch (front) ON

(UP operation)

Battery voltage

Other than above

0

PIIA4805E