Nissan Pathfinder (2007 year). Manual - part 356

SUNROOF

RF-25

C

D

E

F

G

H

J

K

L

M

A

B

RF

2007 Pathfinder

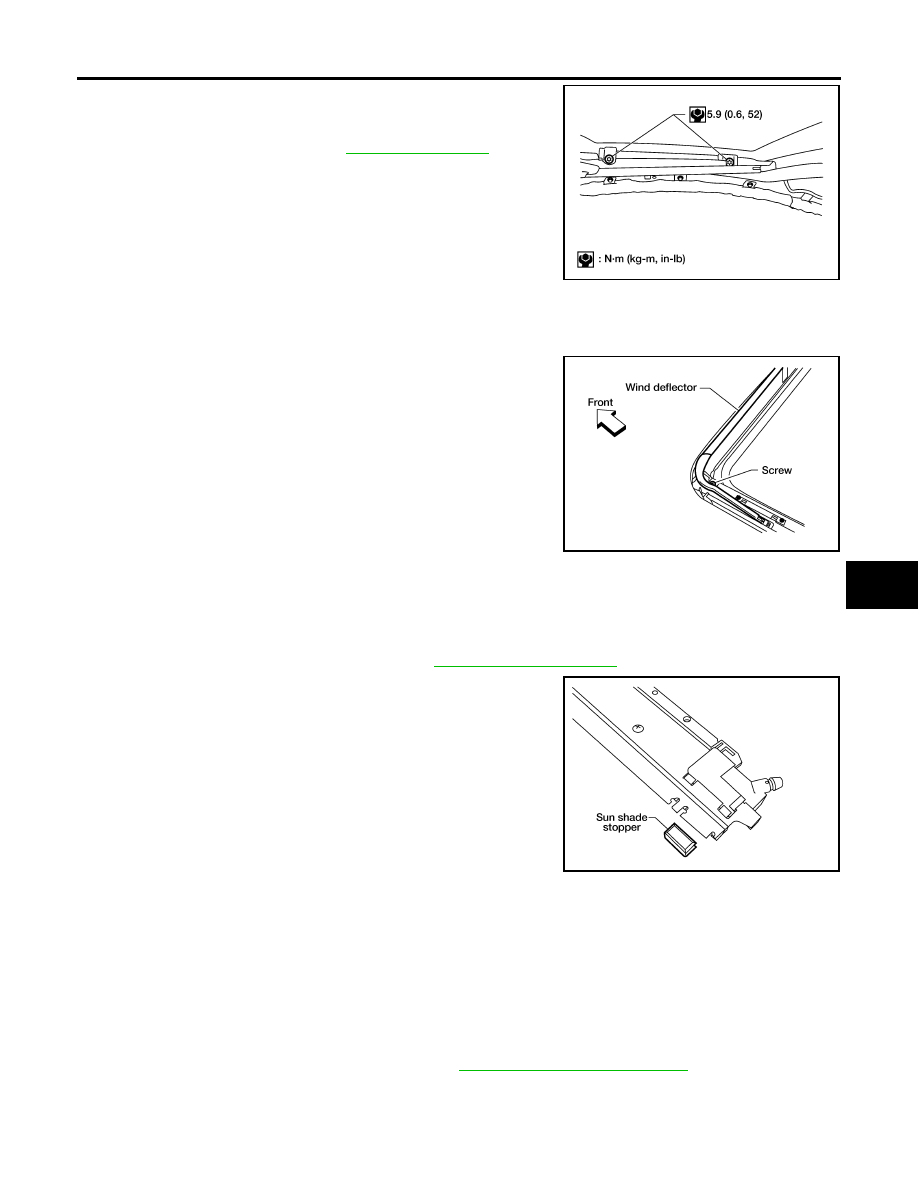

2.

Install the glass lid assembly screws. (First tighten left front bolt,

then tighten right rear bolt on glass lid to prevent lid from moving

while tightening other bolts.)

3.

Adjust the sunroof glass. Refer to

WIND DEFLECTOR

Removal

1.

Open the sunroof.

2.

Remove screws from the left, center, and right side wind deflec-

tor holders.

3.

Remove the wind deflector from the sunroof frame assembly.

Installation

Installation is in the reverse order of removal.

SUNSHADE

Removal

1.

Remove the sunroof frame assembly. Refer to

2.

Remove the sunshade stoppers (2 points) from the rear end of

the sunroof frame assembly.

3.

Remove the sunshade assembly from the rear end of the sun-

roof frame assembly.

Installation

Installation is in the reverse order of removal.

SUNROOF MOTOR

Removal

CAUTION:

●

When removing the sunroof motor, be sure that the sunroof is in the fully closed position.

●

Never run the removed motor as a single unit.

1.

Position the sunroof assembly in the fully closed position.

2.

Remove the front roof console assembly. Refer to

EI-31, "Removal and Installation"

WIIA0252E

WIIA0424E

LIIA1672E