Nissan Pathfinder (2007 year). Manual - part 268

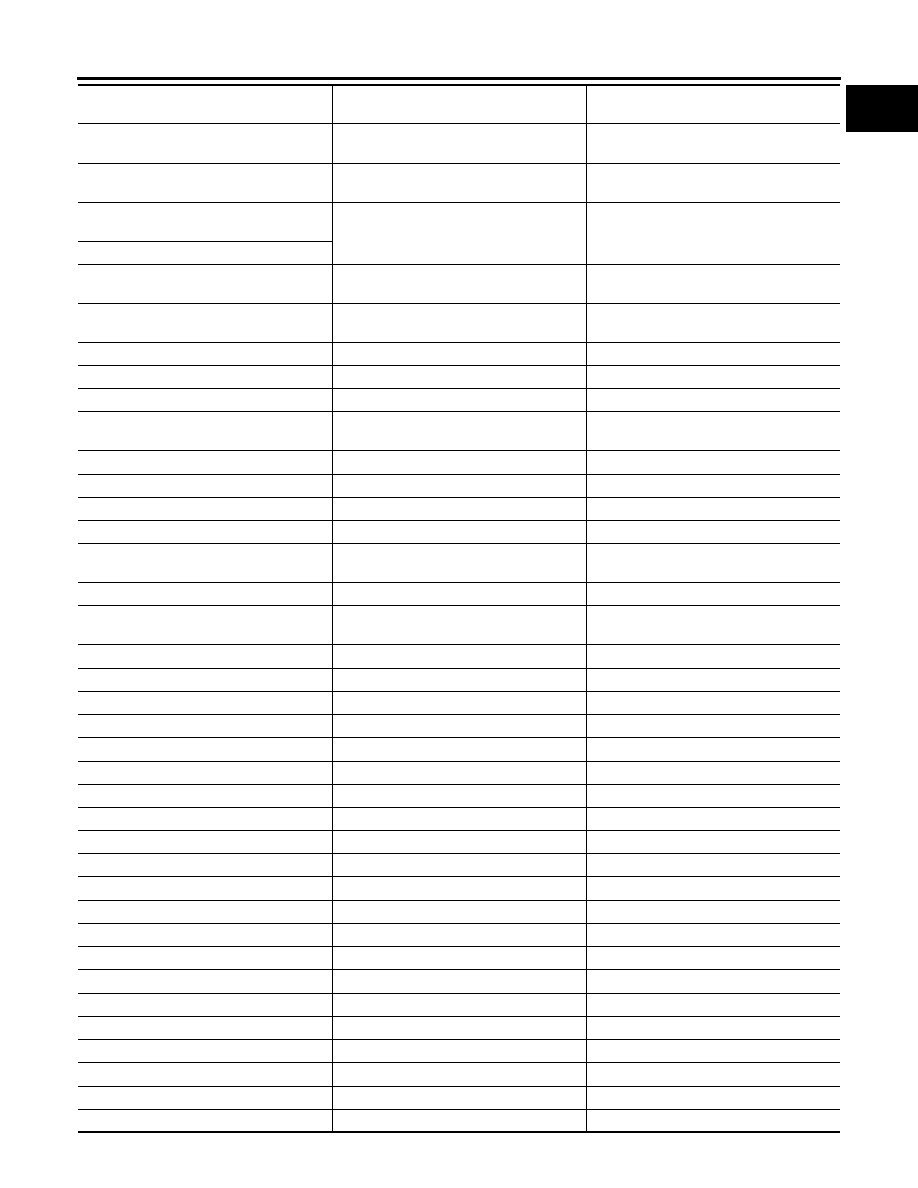

TERMINOLOGY

GI-53

C

D

E

F

G

H

I

J

K

L

M

B

GI

2007 Pathfinder

Exhaust gas recirculation control-BPT

valve

EGRC-BPT valve

BPT valve

Exhaust gas recirculation control-solenoid

valve

EGRC-solenoid valve

EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor

EGRT sensor

Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memory

FEEPROM

***

Flash erasable programmable read only

memory

FEPROM

***

Flexible fuel sensor

FFS

***

Flexible fuel system

FF system

***

Fuel pressure regulator

***

Pressure regulator

Fuel pressure regulator control solenoid

valve

***

PRVR control solenoid valve

Fuel trim

FT

***

Heated Oxygen sensor

HO2S

Exhaust gas sensor

Idle air control system

IAC system

Idle speed control

Idle air control valve-air regulator

IACV-air regulator

Air regulator

Idle air control valve-auxiliary air control

valve

IACV-AAC valve

Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve

IACV-FICD solenoid valve

FICD solenoid valve

Idle air control valve-idle up control sole-

noid valve

IACV-idle up control solenoid valve

Idle up control solenoid valve

Idle speed control-FI pot

ISC-FI pot

FI pot

Idle speed control system

ISC system

***

Ignition control

IC

***

Ignition control module

ICM

***

Indirect fuel injection system

IFI system

***

Intake air

IA

Air

Intake air temperature sensor

IAT sensor

Air temperature sensor

Knock

***

Detonation

Knock sensor

KS

Detonation sensor

Malfunction indicator lamp

MIL

Check engine light

Manifold absolute pressure

MAP

***

Manifold absolute pressure sensor

MAPS

***

Manifold differential pressure

MDP

***

Manifold differential pressure sensor

MDPS

***

Manifold surface temperature

MST

***

Manifold surface temperature sensor

MSTS

***

Manifold vacuum zone

MVZ

***

Manifold vacuum zone sensor

MVZS

***

Mass air flow sensor

MAFS

Air flow meter

Mixture control solenoid valve

MC solenoid valve

Air-fuel ratio control solenoid valve

Multiport fuel injection System

MFI system

Fuel injection control

NEW TERM

NEW ACRONYM /

ABBREVIATION

OLD TERM