Nissan Pathfinder (2007 year). Manual - part 258

PREPARATION

FSU-3

C

D

F

G

H

I

J

K

L

M

A

B

FSU

2007 Pathfinder

PREPARATION

PFP:00002

Special Service Tools

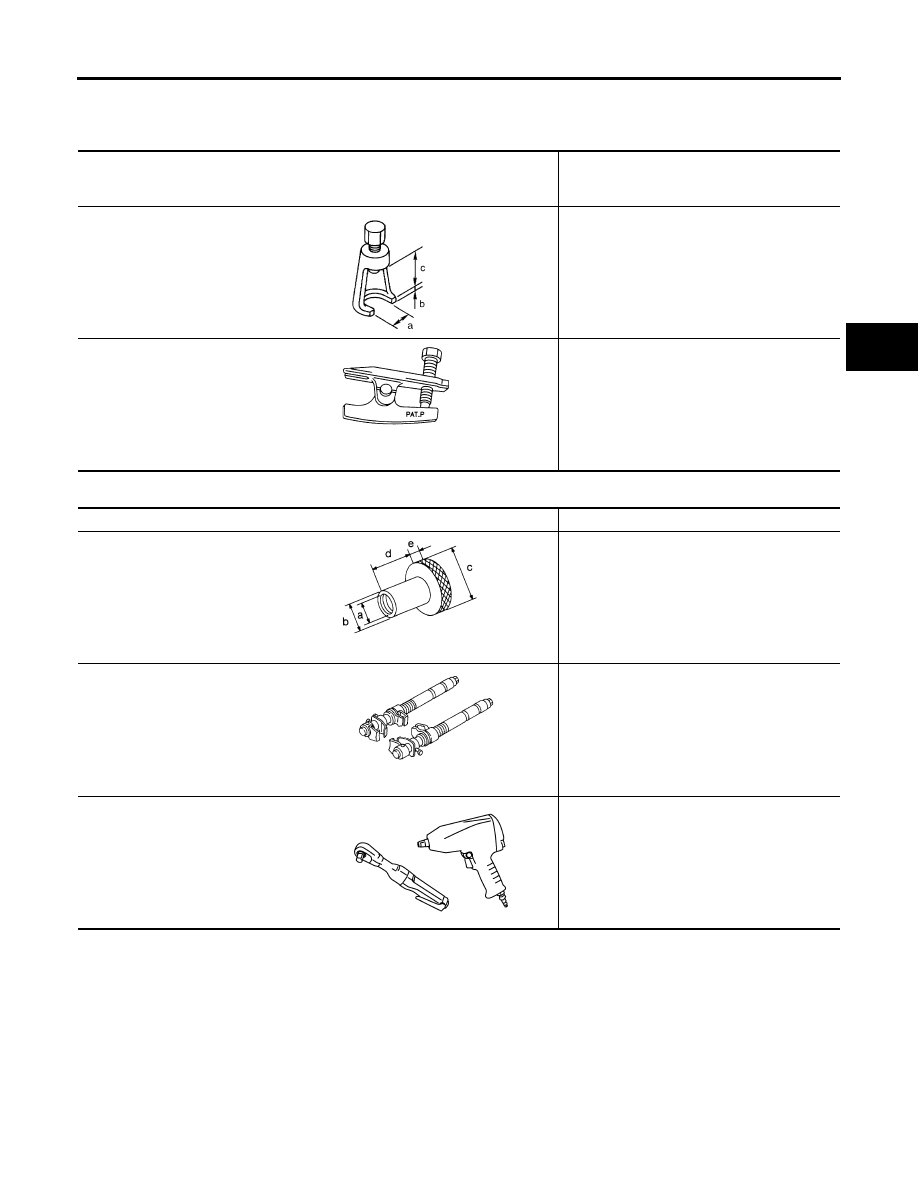

EES0022P

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service Tools

EES0022Q

Tool number

(Kent-Moore No.)

Tool name

Description

ST29020001

(J-24319-01)

Gear arm puller

Removing ball joint for knuckle

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

HT72520000

(J-25730-A)

Ball joint remover

Removing tie-rod outer end

NT694

NT146

Tool name

Description

Attachment wheel alignment

Measuring wheel alignment

a: Screw M24 x 1.5 pitch

b: 35 mm (1.38 in) dia.

c: 65 mm (2.56 in) dia.

d: 56 mm (2.20 in)

e: 12 mm (0.47 in)

Spring compressor

Removing and installing coil spring

Power tool

Loosening bolts and nuts

NT148

NT717

PBIC0190E