Nissan Pathfinder (2007 year). Manual - part 161

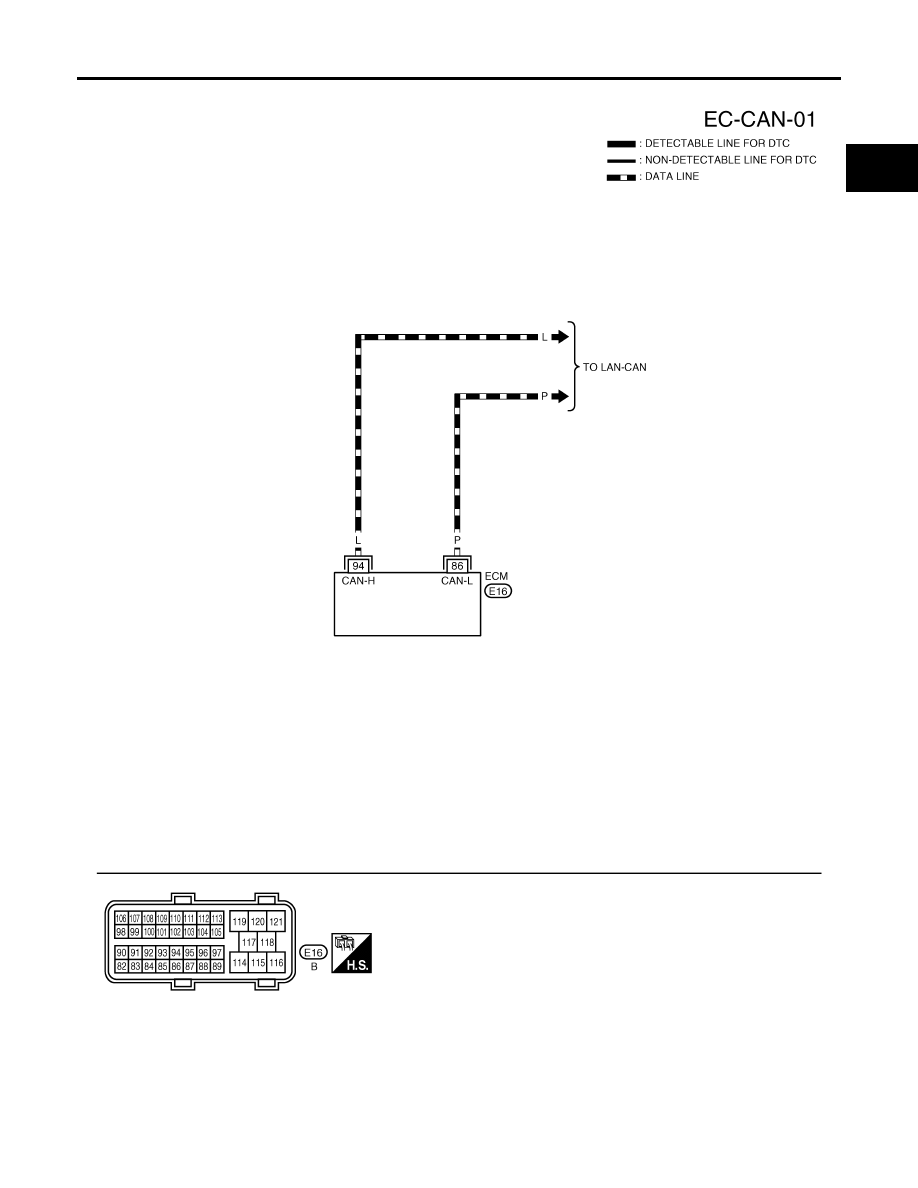

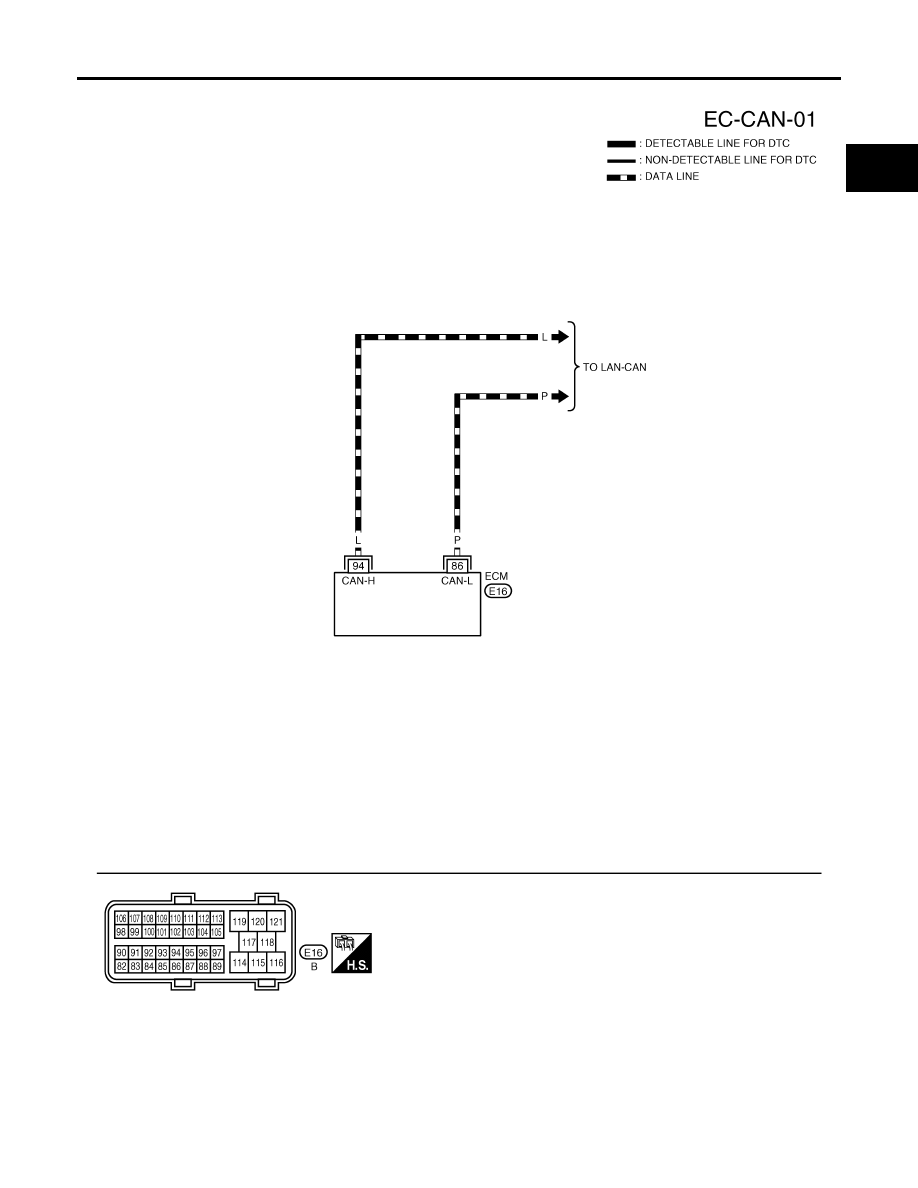

DTC U1000, U1001 CAN COMMUNICATION LINE

EC-155

C

D

E

F

G

H

I

J

K

L

M

A

EC

2007 Pathfinder

Wiring Diagram

UBS00K4S

BBWA2359E

|

|

|

DTC U1000, U1001 CAN COMMUNICATION LINE EC-155 C D E F G H I J K L M A EC 2007 Pathfinder Wiring Diagram UBS00K4S BBWA2359E |