Nissan Pathfinder (2007 year). Manual - part 131

G SENSOR

BRC-133

[HDC/HSA/VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

2007 Pathfinder

G SENSOR

PFP:47930

Removal and Installation

EFS0067R

REMOVAL

1.

Remove center console. Refer to

2.

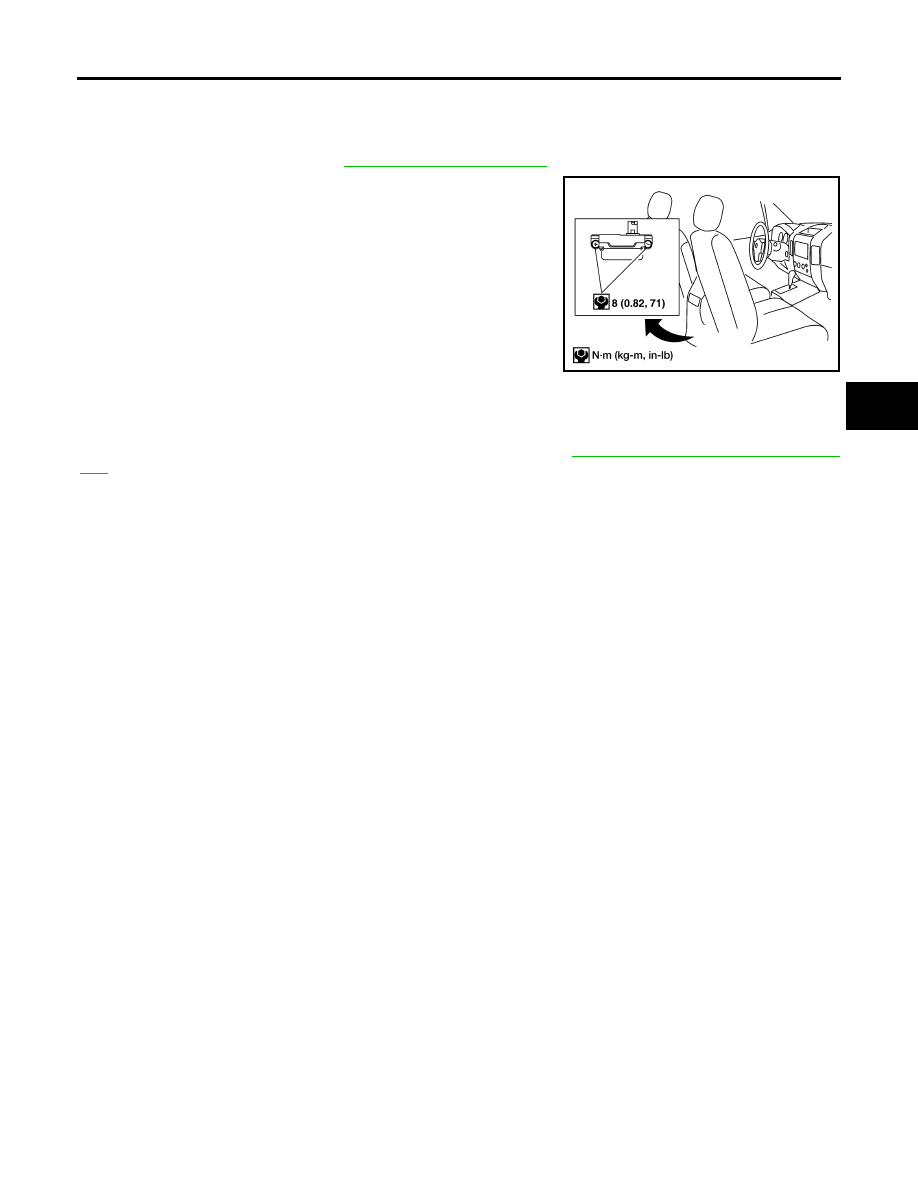

Remove yaw rate/side/decel G sensor nuts as shown.

●

The location of the sensor is the same for all models.

CAUTION:

●

Do not use power tools to remove or install yaw rate/side/

decel G sensor.

●

Do not drop or strike the yaw rate/side/decel G sensor.

3.

Disconnect harness connector and remove the yaw rate/side/

decel G sensor.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

After performing the above work, calibrate the decel G sensor. Refer to

BRC-126, "Calibration of Decel G Sen-

WFIA0230E