Nissan Pathfinder (2007 year). Manual - part 121

TROUBLE DIAGNOSES FOR SYMPTOMS

BRC-53

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

2007 Pathfinder

Unexpected Pedal Action

EFS0065O

1.

CHECK WARNING LAMP ACTIVATION

Make sure warning lamp remains off while driving.

OK or NG

OK

>> GO TO 2.

NG

>> Carry out self-diagnosis. Refer to

.

2.

CHECK BRAKE PEDAL STROKE

Check brake pedal stroke.

Is pedal stroke excessive?

YES

>> Perform Basic Inspection. Refer to

NO

>> GO TO 3.

3.

CHECK CONNECTOR AND BRAKING PERFORMANCE

1.

Disable ABS by disconnecting ABS actuator and electric unit (control unit) connector.

2.

Drive vehicle and check brake operation.

NOTE:

●

Stopping distance may be longer than vehicles without ABS when road condition is slippery.

●

Driving the vehicle with the ABS actuator and electric unit (control unit) disconnected may induce DTCs

in electrical control units using CAN communication. After the inspection, clear all DTCs. Refer to

.

OK or NG

OK

>> GO TO 4.

NG

>> Perform Basic Inspection. Refer to

4.

CHECK WHEEL SENSORS

Check the following.

●

Wheel sensor mounting for looseness

●

Wheel sensors for physical damage

●

Wheel sensor connectors for terminal damage or loose connections

OK or NG

OK

>> Check ABS actuator and electric unit (control unit) connector terminals for deformation, discon-

nection, looseness or damage. Reconnect ABS actuator and electric unit (control unit) harness

connector. Then retest.

NG

>> Repair or replace as necessary.

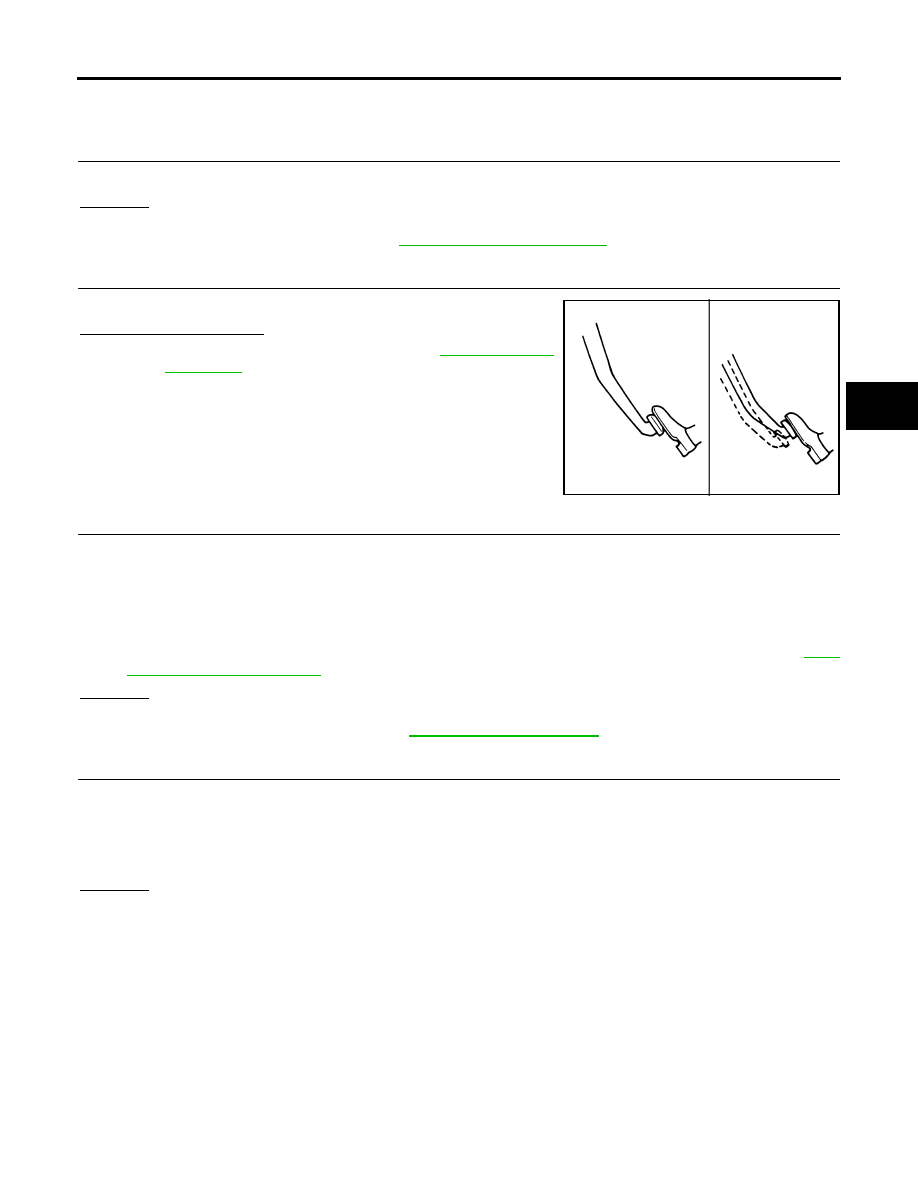

SBR540A