Nissan Pathfinder (2006 year). Manual - part 357

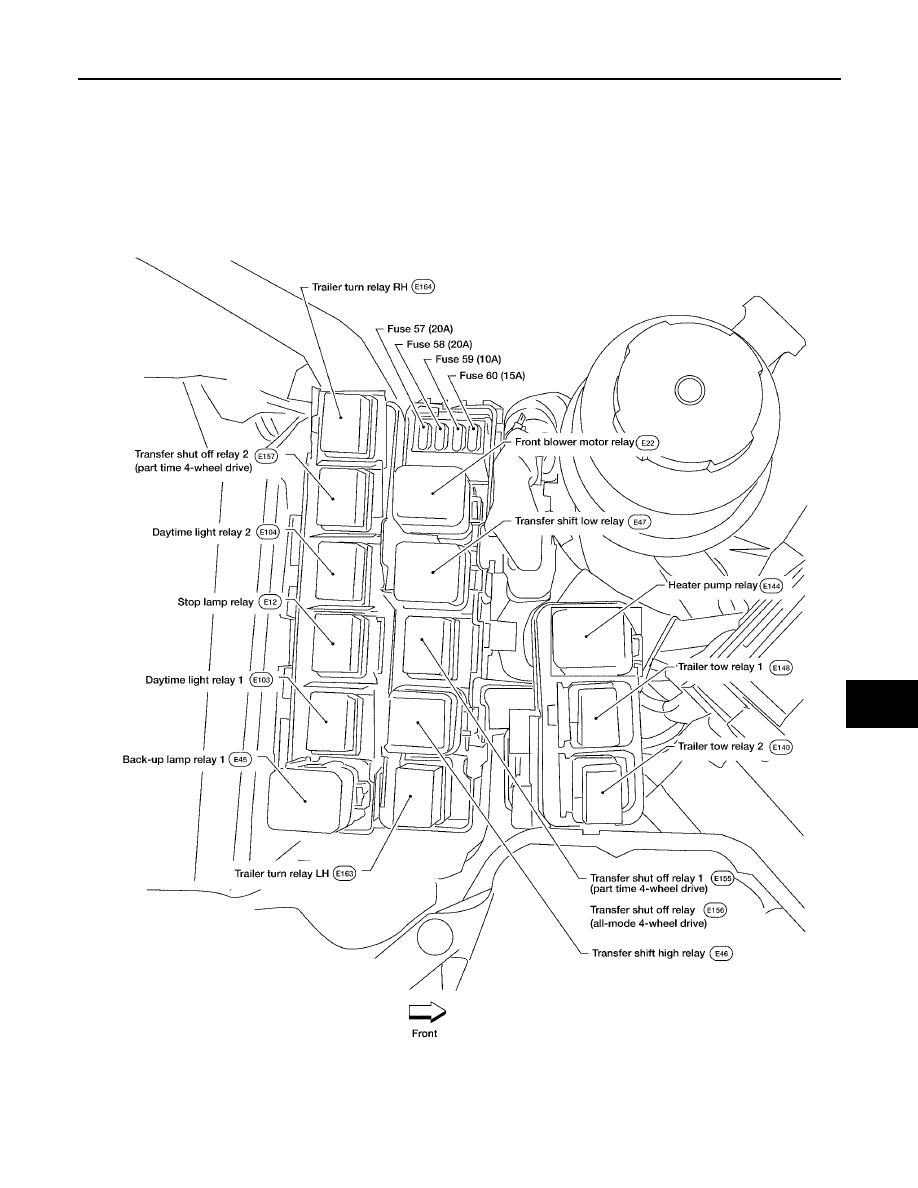

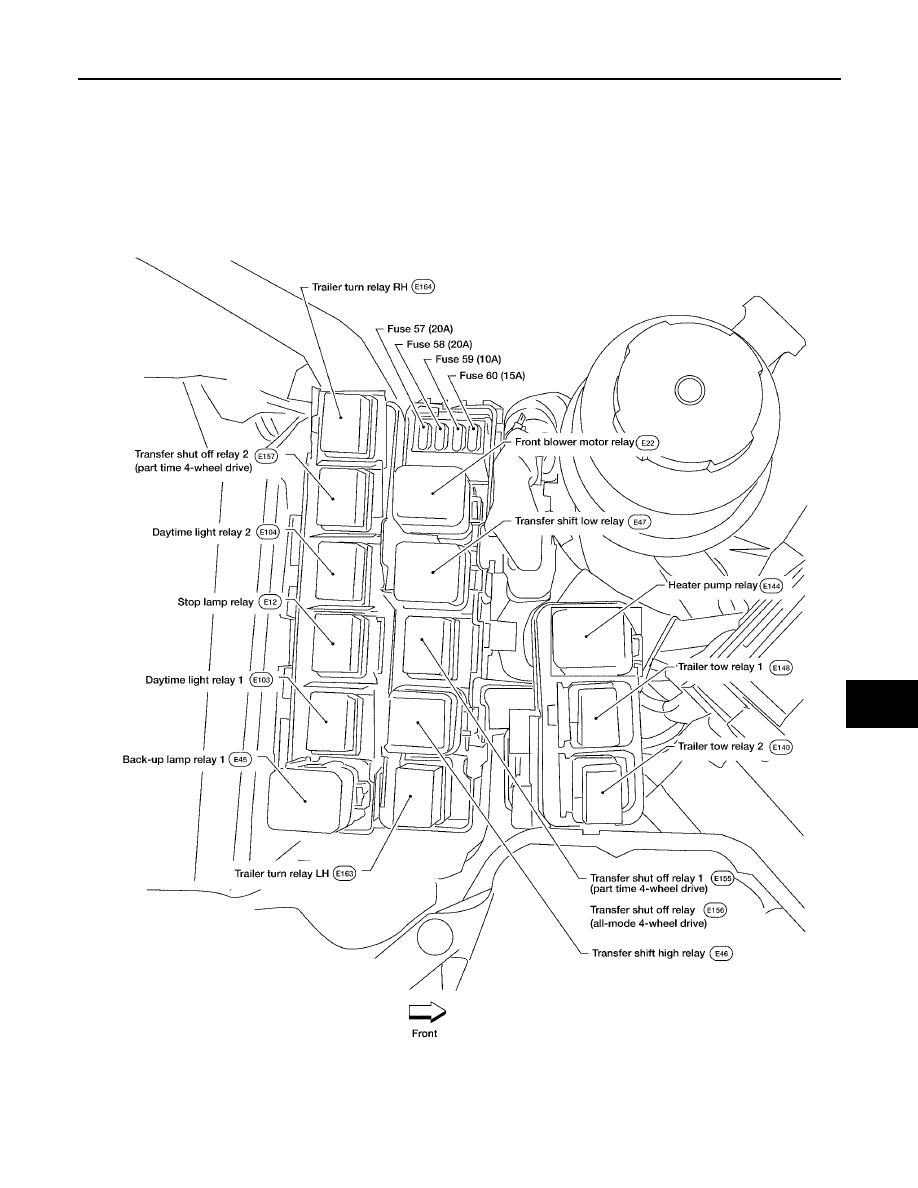

FUSE AND RELAY BOX

PG-85

C

D

E

F

G

H

I

J

L

M

A

B

PG

2006 Pathfinder

FUSE AND RELAY BOX

PFP:24012

Terminal Arrangement

EKS00G91

WKIA5014E

|

|

|

FUSE AND RELAY BOX PG-85 C D E F G H I J L M A B PG 2006 Pathfinder FUSE AND RELAY BOX PFP:24012 Terminal Arrangement EKS00G91 WKIA5014E |