Nissan Pathfinder (2006 year). Manual - part 329

ENGINE MAINTENANCE

MA-19

C

D

E

F

G

H

I

J

K

M

A

B

MA

2006 Pathfinder

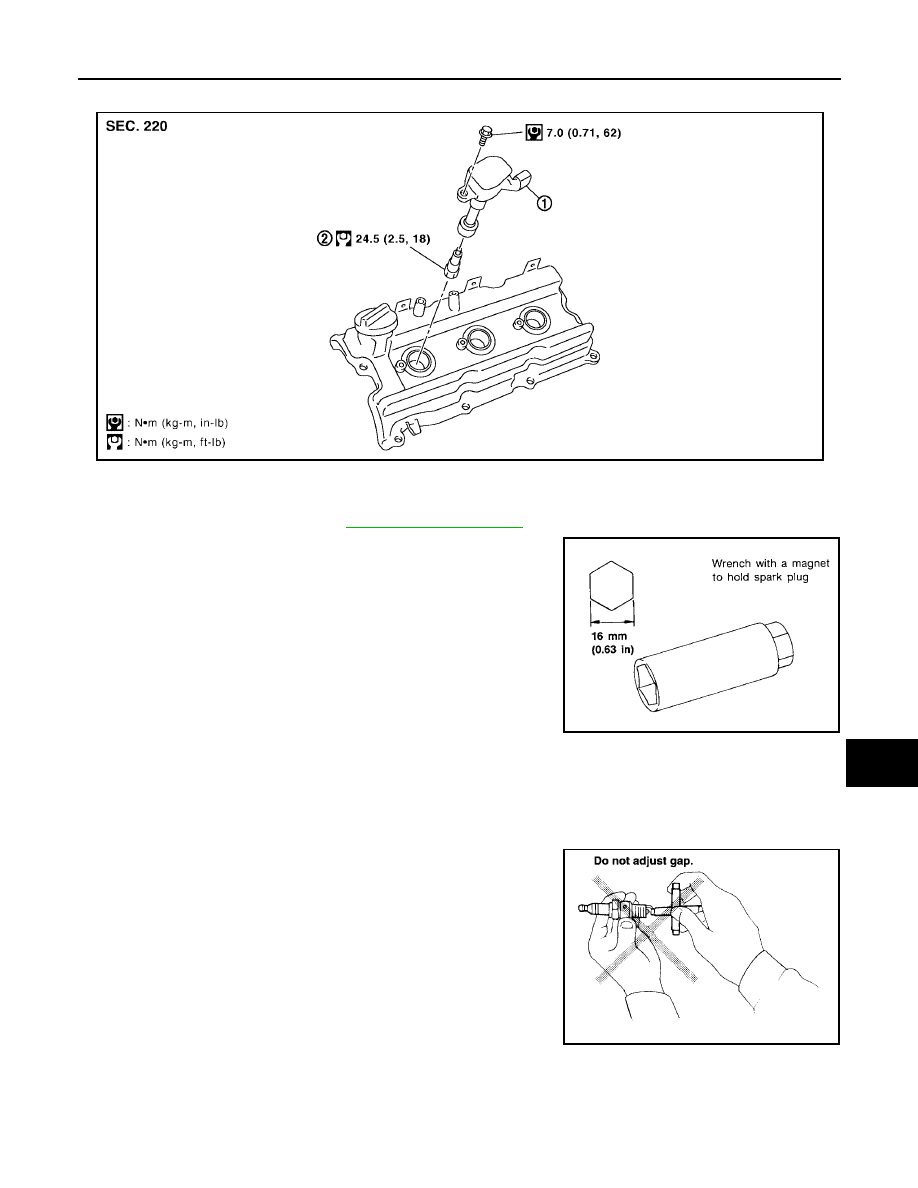

Changing Spark Plugs

ELS001OM

REMOVAL

1.

Remove the ignition coil. Refer to

.

2.

Remove the spark plug using a suitable tool as shown.

CAUTION:

Do not drop or shock the spark plug if reusing it.

INSPECTION AFTER REMOVAL

●

If plug tip is covered with carbon, spark plug cleaner may be used.

●

Checking and adjusting plug gap is not required between

change intervals.

1.

Ignition coil

2.

Spark plug

PBIC2901E

SEM294A

Cleaner air pressure

: Less than 588 kPa (6 kg/cm

2

, 85 psi)

Cleaning time

: Less than 20 seconds

SMA806CA