Nissan Pathfinder (2006 year). Manual - part 263

CONSULT-II CHECKING SYSTEM

GI-41

C

D

E

F

G

H

I

J

K

L

M

B

GI

2006 Pathfinder

NOTE:

The DDL1 circuits (CAN lines) from DLC pins 6 and 14 as well as the DDL2 circuit (K-line) from DLC pin 7 are

connected to more than one system. A short in a DDL circuit connected to a control unit in one system may

affect CONSULT-II access to other systems.

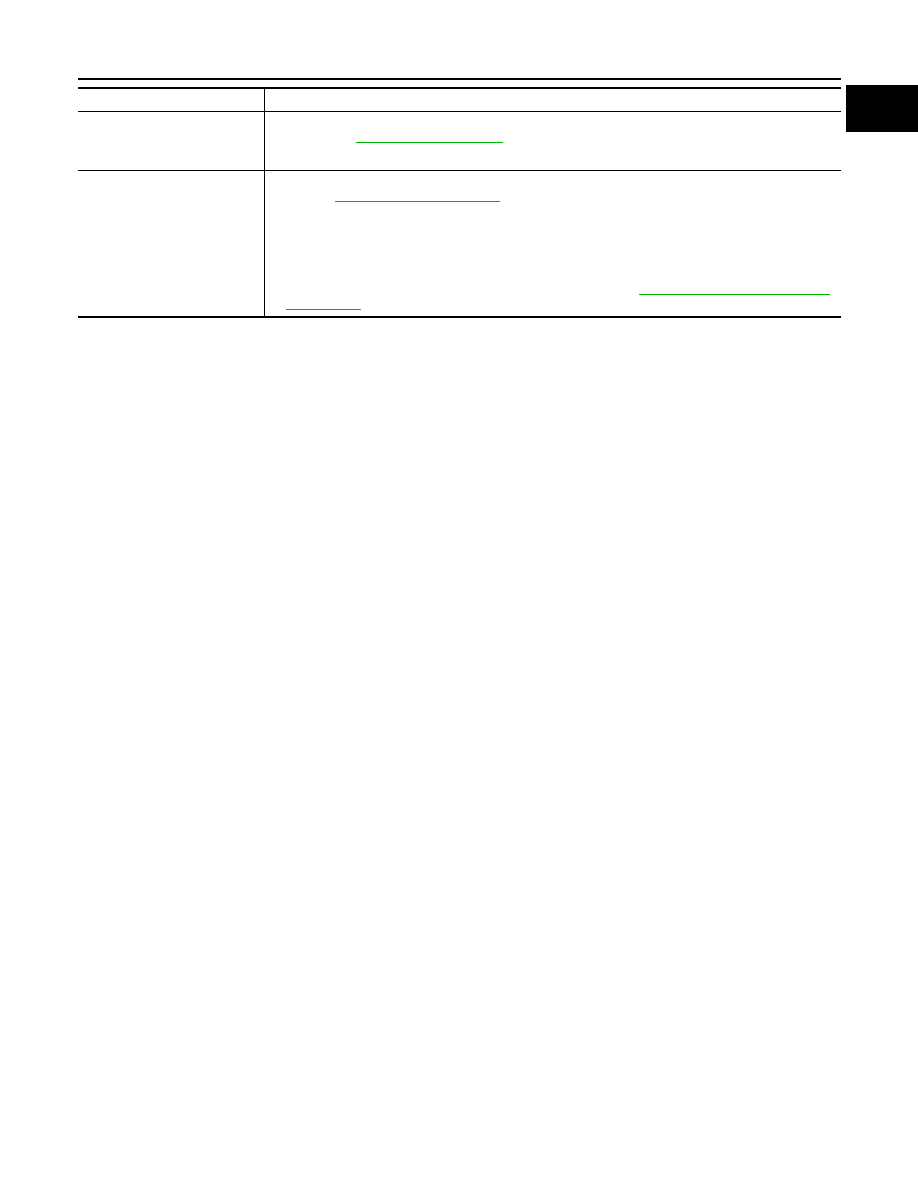

Symptom

Check item

CONSULT-II cannot access

any system.

●

CONSULT-II DLC power supply circuit (Terminal 8) and ground circuit (Terminal 4). For detailed cir-

cuit, refer to

.

●

CONSULT-II DLC cable and CONSULT-II CONVERTER.

CONSULT-II cannot access

individual system. (Other sys-

tems can be accessed.)

●

CONSULT-II program card (Check the appropriate CONSULT-II program card for the system.

Refer to

●

Power supply and ground circuit for the control unit of the system (For detailed circuit, refer to wir-

ing diagram for each system.)

●

Open or short circuit between the system and CONSULT-II DLC (For detailed circuit, refer to wiring

diagram for each system.)

●

Open or short circuit in CAN or K communication line. Refer to

LAN-3, "Precautions When Using

.