Nissan Pathfinder (2006 year). Manual - part 261

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-25

C

D

E

F

G

H

I

J

K

L

M

B

GI

2006 Pathfinder

●

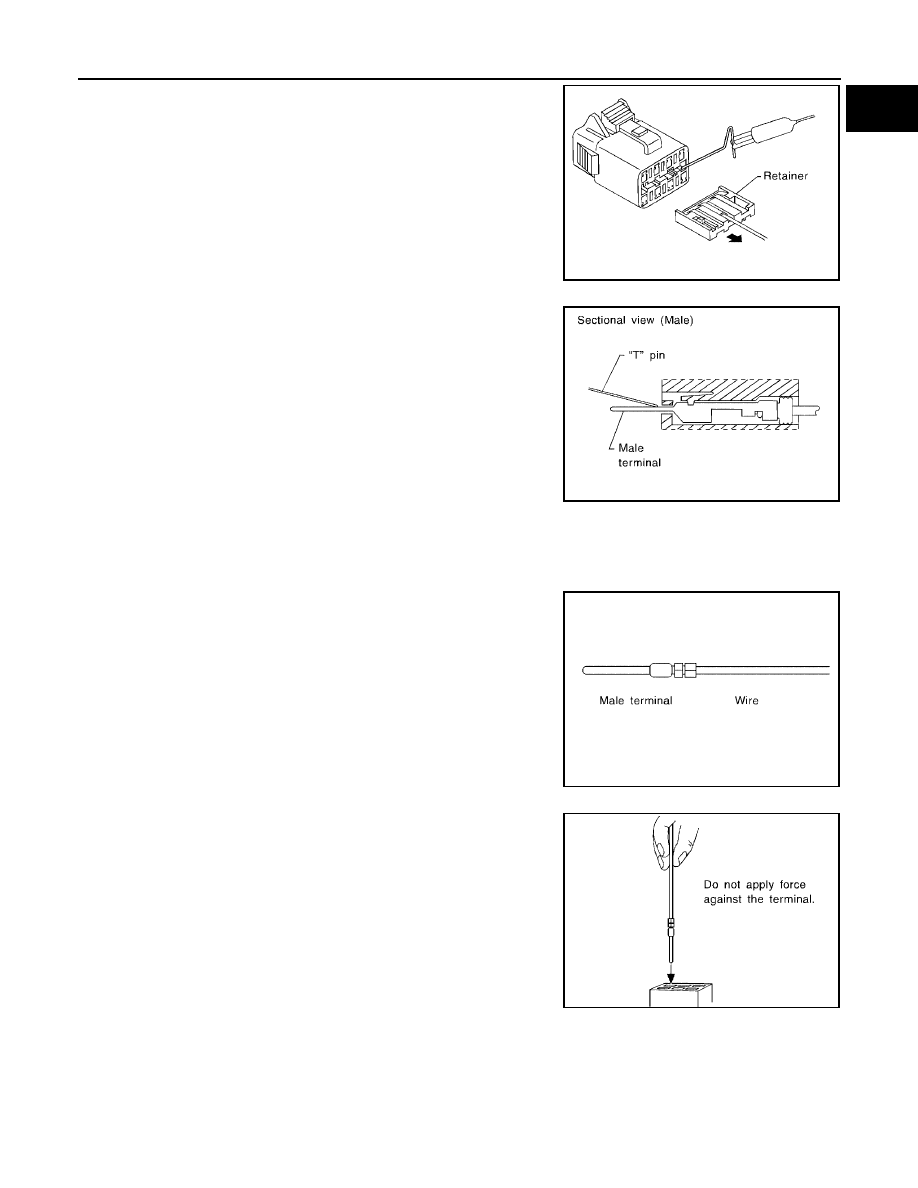

Some connectors do not have a notch above each terminal. To

probe each terminal, remove the connector retainer to make

contact space for probing.

MALE TERMINAL

Carefully probe the contact surface of each terminal using a “T” pin.

Do not bend terminal.

How to Check Enlarged Contact Spring of Terminal

An enlarged contact spring of a terminal may create intermittent signals in the circuit.

If the intermittent open circuit occurs, follow the procedure below to inspect for open wires and enlarged con-

tact spring of female terminal.

1.

Assemble a male terminal and approx. 10 cm (3.9 in) of wire.

Use a male terminal which matches the female terminal.

2.

Disconnect the suspected faulty connector and hold it terminal

side up.

3.

While holding the wire of the male terminal, try to insert the male

terminal into the female terminal.

Do not force the male terminal into the female terminal with

your hands.

SEL266V

SEL267V

SEL270V

SEL271V