Nissan Pathfinder (2006 year). Manual - part 251

WHEEL HUB

FAX-5

C

E

F

G

H

I

J

K

L

M

A

B

FAX

2006 Pathfinder

WHEEL HUB

PFP:43202

On-Vehicle Inspection and Service

EDS003AB

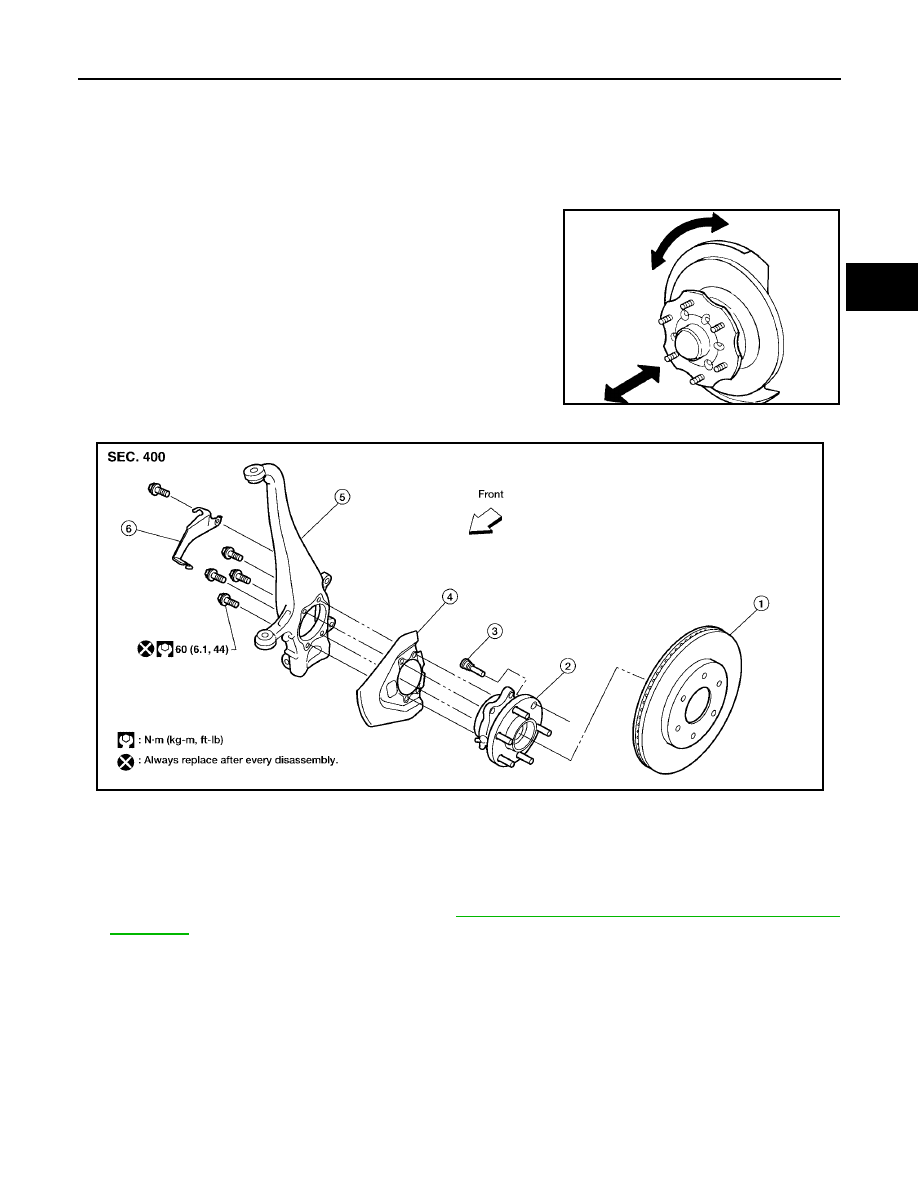

Make sure the mounting conditions (looseness, backlash) of each component and component status (wear,

damage) are normal.

WHEEL BEARING INSPECTION

●

Move wheel hub in the axial direction by hand. Make sure there

is no looseness of wheel bearing.

●

Rotate wheel hub and make sure there is no unusual noise or

other irregular conditions. If there are any irregular conditions,

replace wheel hub and bearing assembly.

Removal and Installation

EDS003AC

REMOVAL

1.

Remove wheel and tire using power tool.

2.

Without disassembling the hydraulic lines, remove caliper torque member bolts using power tool. Then

reposition brake caliper aside with wire. Refer to

BR-25, "Removal and Installation of Brake Caliper and

CAUTION:

Do not press brake pedal while brake caliper is removed.

Axial end play limit

: 0.05 mm (0.002 in) or less

SMA571A

1.

Disc rotor

2.

Wheel hub and bearing assembly

3.

Wheel stud

4.

Splash guard

5.

Steering knuckle

6.

Wheel sensor bracket

WDIA0228E