Nissan Teana J32. Manual - part 998

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-125

< SYMPTOM DIAGNOSIS >

[WITHOUT VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

M

A

B

SE

N

O

P

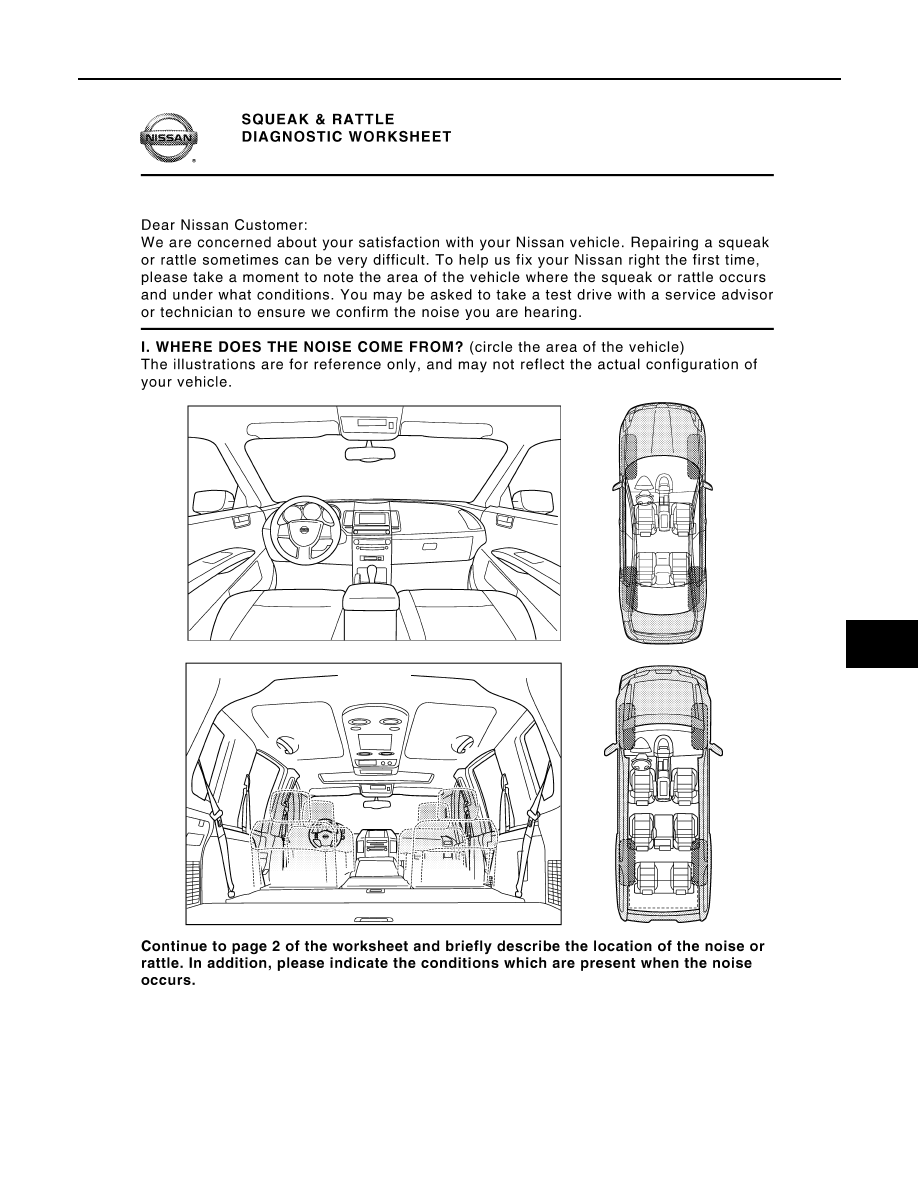

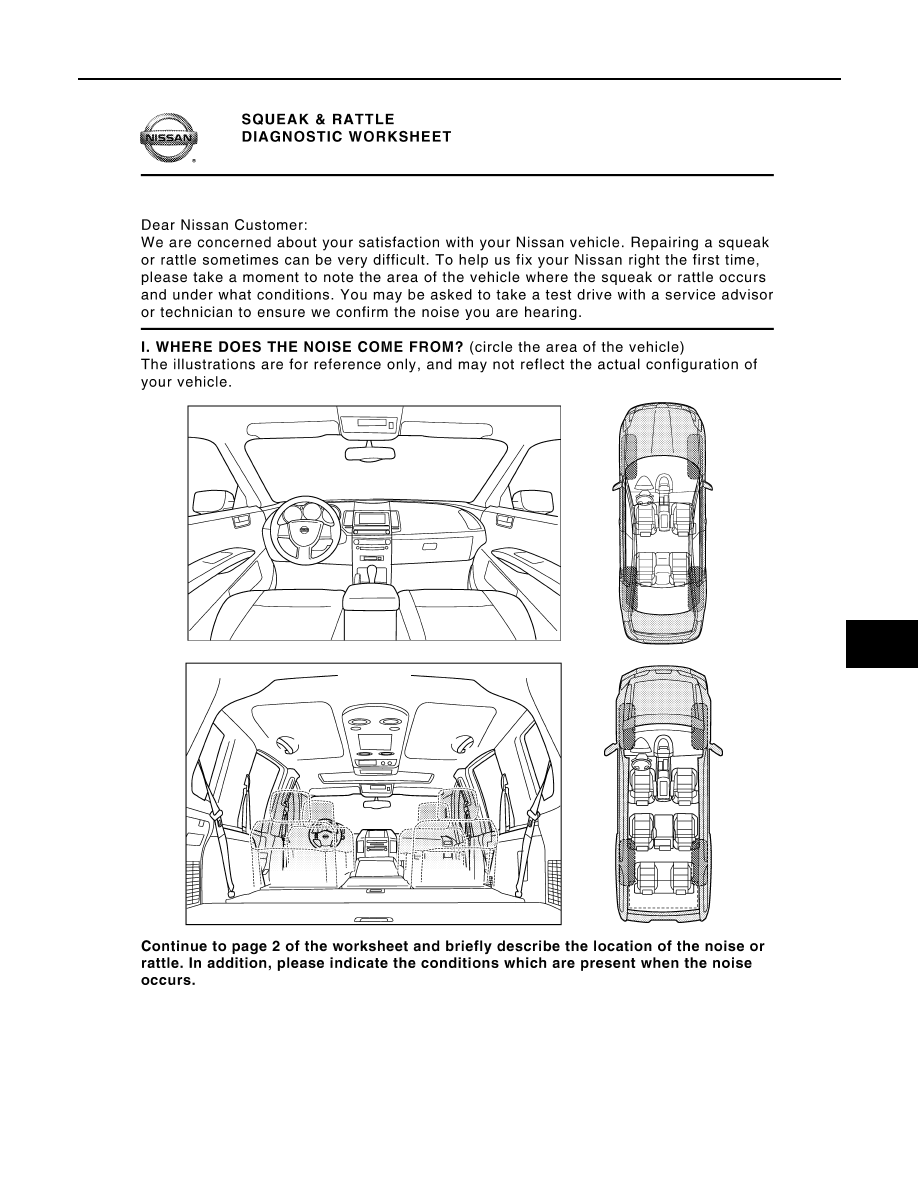

Diagnostic Worksheet

INFOID:0000000003940142

PIIB8740E

|

|

|

SQUEAK AND RATTLE TROUBLE DIAGNOSES SE-125 < SYMPTOM DIAGNOSIS > [WITHOUT VENTILATION SEAT] C D E F G H I K L M A B SE N O P Diagnostic Worksheet INFOID:0000000003940142 PIIB8740E |