Nissan Teana J32. Manual - part 807

CHASSIS MAINTENANCE

MA-37

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

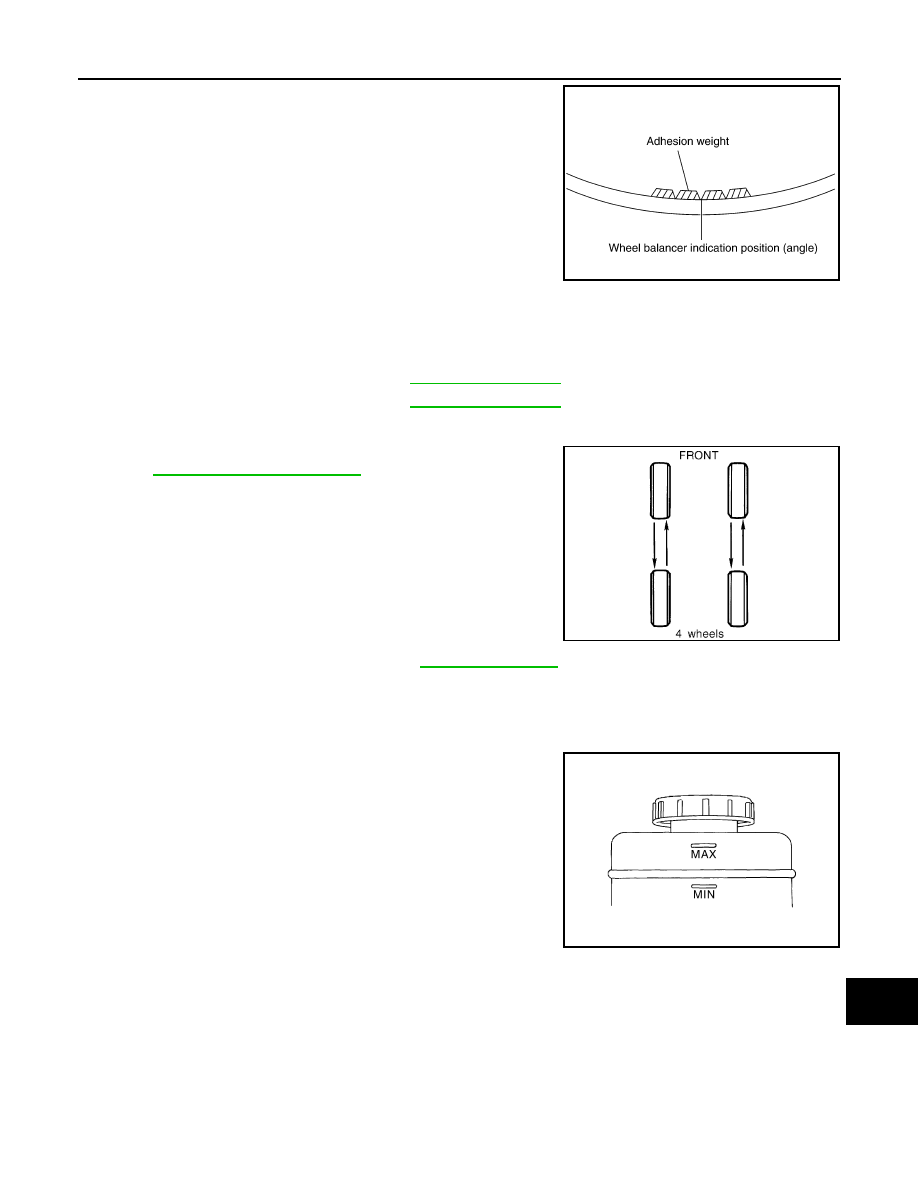

c.

If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Do not install one balance weight sheet on top of another.

3.

Start the tire balance machine again.

4.

Install drive-in balance weight on inner side of road wheel in the

tire balance machine indication position (angle).

CAUTION:

Do not install more than two balance weight.

5.

Start the tire balance machine. Make sure that inner and outer

residual unbalance values are 5 g (0.17 oz) each or below.

6.

If either residual unbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

TIRE ROTATION

• Follow the maintenance schedule for tire rotation service intervals.

• When installing the wheel, tighten wheel nuts to the specified

torque.

CAUTION:

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wheel nut at torque exceeding the

criteria for preventing strain of disc rotor.

• Use NISSAN genuine wheel nuts for aluminum wheels.

BRAKE FLUID LEVEL AND LEAKS

BRAKE FLUID LEVEL AND LEAKS : Inspection

INFOID:0000000003858309

• If fluid level is extremely low, check brake system for leaks.

BRAKE LINES AND CABLES

Limit

Dynamic (At rim flange):

.

Static (At rim flange):

.

PEIA0033E

Wheel nuts tighting torque

: Refer to

SMA829C

JPFIA0007ZZ