Nissan Teana J32. Manual - part 675

BLOWER MOTOR

HAC-69

< COMPONENT DIAGNOSIS >

[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

2.

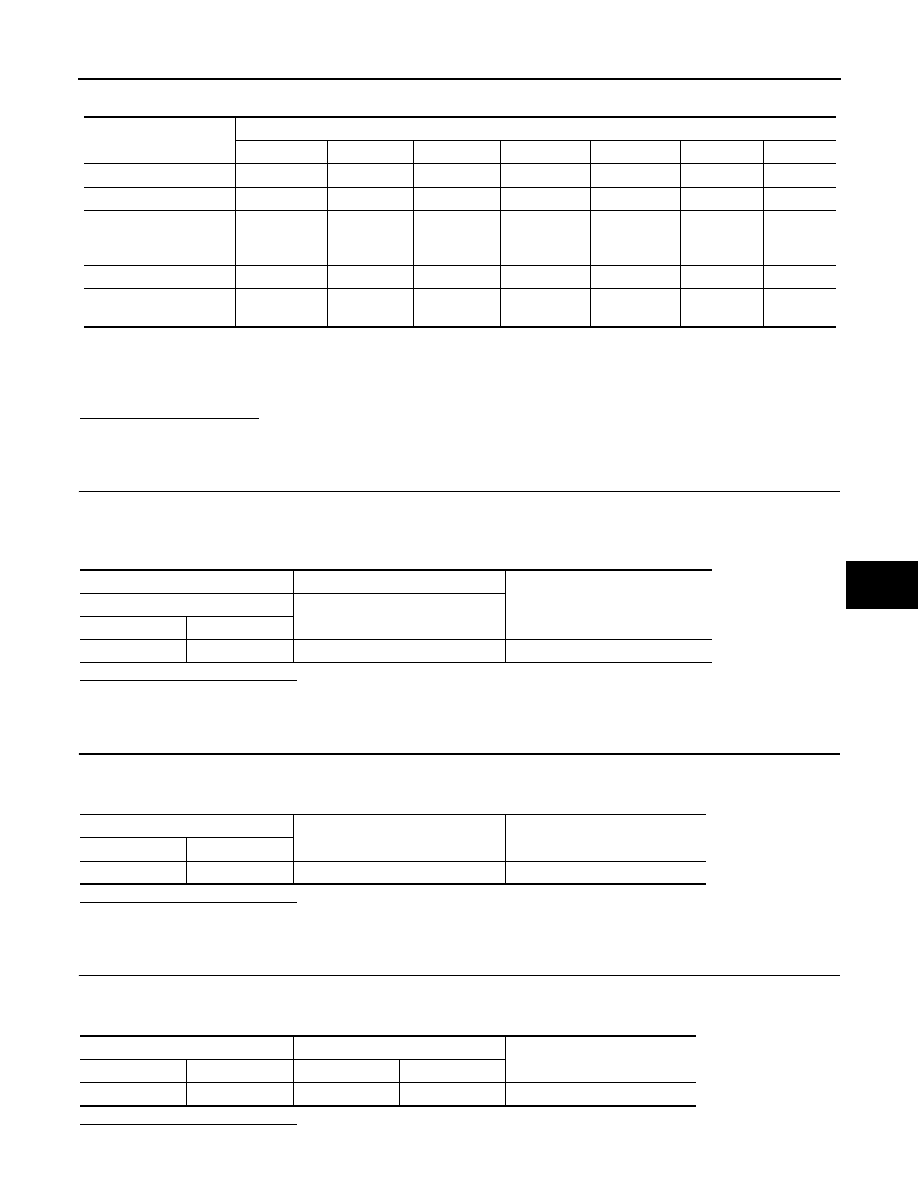

Check that the blower motor control signal changes according to each indicator signal.

NOTE:

• Perform the inspection of each output device after starting the engine because the compressor is oper-

ated.

• When choosing to “MODE 7”, error message is displayed but it is not malfunction.

Does it operate normally?

YES

>> INSPECTION END

NO

>> GO TO 3.

3.

CHECK POWER SUPPLY FOR BLOWER MOTOR

1.

Disconnect blower motor connector.

2.

Turn ignition switch ON.

3.

Check voltage between blower motor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> GO TO 7.

4.

CHECK BLOWER MOTOR GROUND CIRCUIT

1.

Turn ignition switch OFF.

2.

Check continuity between blower motor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair harness or connector.

5.

CHECK BLOWER MOTOR CIRCUIT CONTINUITY

1.

Disconnect A/C auto amp. connector.

2.

Check continuity between blower motor harness connector and A/C auto amp. harness connector.

Is the inspection result normal?

Test item

MODE 1

MODE 2

MODE 3

MODE 4

MODE 5

MODE 6

MODE 7

Mode door position

VENT

B/L1

B/L2

AUTO FOOT

D/F

DEF

-

Intake door position

REC

REC

20% FRE

FRE

FRE

FRE

-

Air mix door position

(driver & passenger

side)

FULL COLD

FULL COLD

FULL HOT

FULL HOT

FULL HOT

FULL HOT

-

Blower motor duty ratio

37%

91%

65%

65%

65%

91%

-

Compressor (Magnet

clutch)

ON

ON

OFF

OFF

ON

ON

-

(+)

(

−

)

Voltage

Blower motor

—

Connector

Terminal

M98

1

Ground

Battery voltage

Blower motor

—

Continuity

Connector

Terminal

M98

3

Ground

Existed

Blower motor

A/C auto amp.

Continuity

Connector

Terminal

Connector

Terminal

M98

2

M50

32

Existed