Nissan Teana J32. Manual - part 487

EM-72

< REMOVAL AND INSTALLATION >

ENGINE ASSEMBLY

• VQ25DE

• VQ35DE

5.

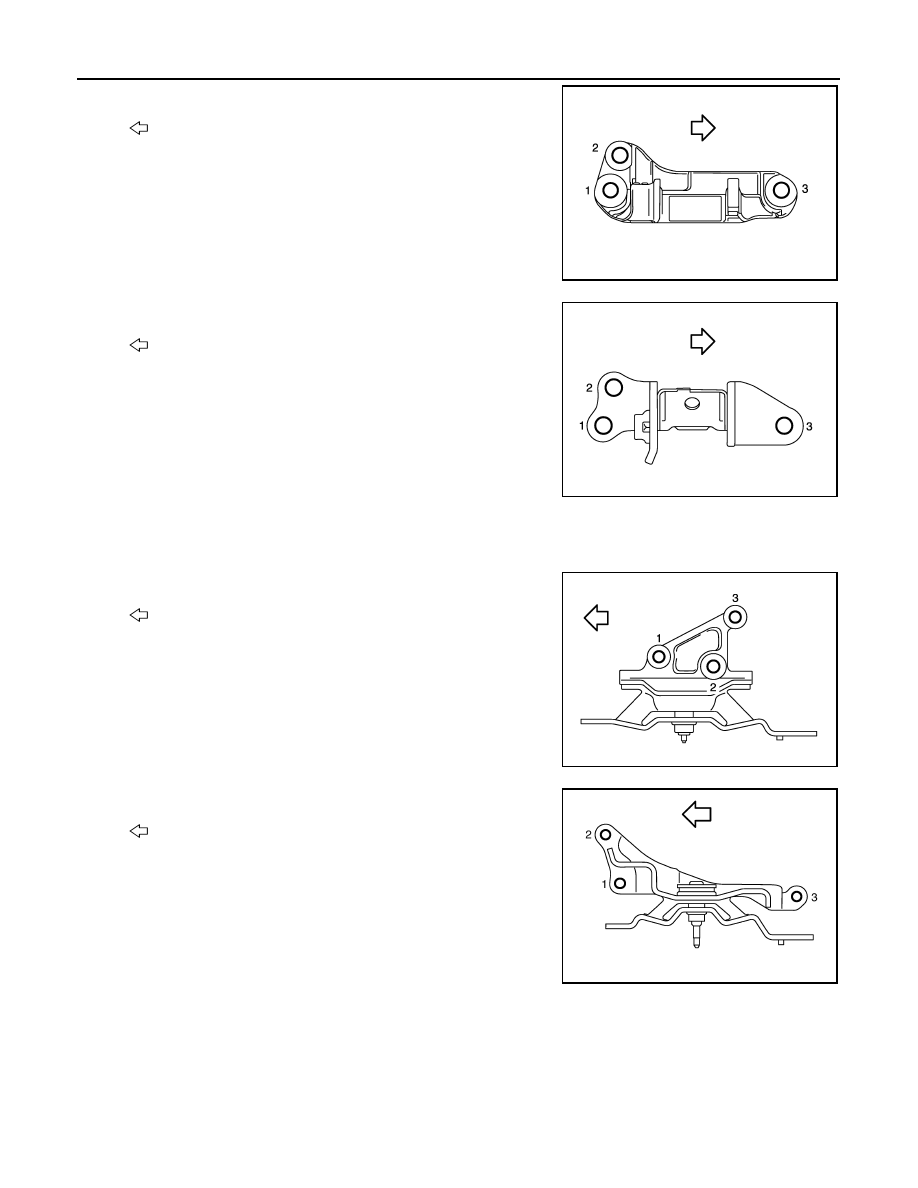

Install the engine mounting insulator (LH) to the transaxle as follows:

a.

Tighten the bolt No. 3 as shown in the figure. (temporarily)

b.

Tighten the bolts in numerical order as shown in the figure. (specified torque)

• VQ25DE

• VQ35DE

6.

Install the engine mounting insulator (front) to the front suspension member as follows:

: Engine front

JPBIA2376ZZ

: Engine front

JPBIA2377ZZ

: Vehicle front

JPBIA2196ZZ

: Vehicle front

JPBIA1734ZZ