Content .. 1191 1192 1193 1194 ..

Nissan Teana J32. Manual - part 1193

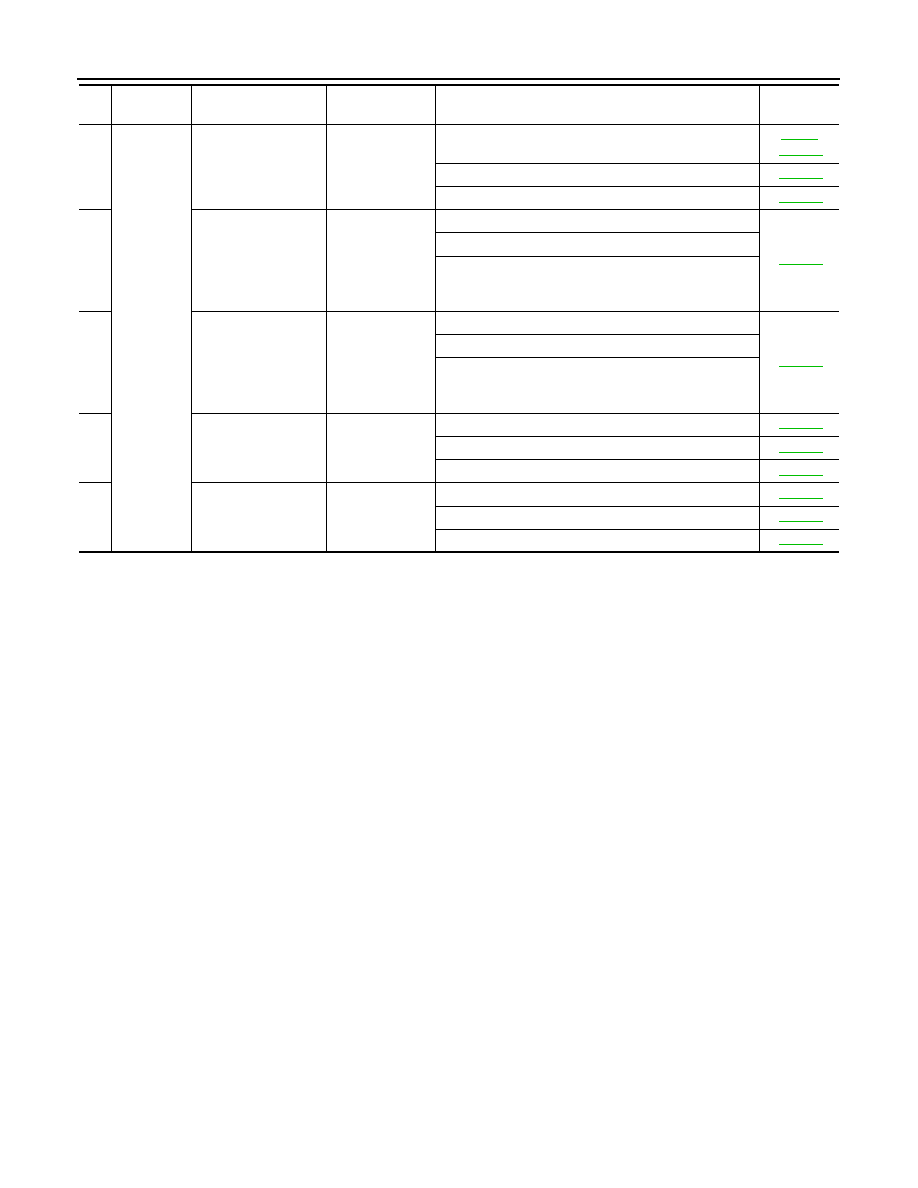

TM-296

< SYMPTOM DIAGNOSIS >

[CVT: RE0F10A]

SYSTEM SYMPTOM

30

Others

Engine starts in posi-

tions other than “N” or

“P”.

ON vehicle

1. Ignition switch and starter

2. CVT position

3. PNP switch

31

When brake pedal is

depressed with igni-

tion switch ON, selec-

tor lever cannot be

shifted from “P” posi-

tion to other position.

ON vehicle

1. Stop lamp switch

2. Shift lock solenoid

3. Control device

32

When brake pedal is

not depressed with ig-

nition switch ON, se-

lector lever can be

shifted from “P” posi-

tion to other position.

ON vehicle

1. Stop lamp switch

2. Shift lock solenoid

3. Control device

33

Cannot be changed to

sport mode.

ON vehicle

1. Sport mode switch

2. CAN communication line

3. Combination meters

33

CVT indicator lamp is

not turned ON.

ON vehicle

1. CAN communication line

2. Combination meters

3. TCM power supply and ground

No

.

Item

Symptom

Condition

Diagnostic Item

Reference