Content .. 1159 1160 1161 1162 ..

Nissan Teana J32. Manual - part 1161

TM-168

< REMOVAL AND INSTALLATION >

[CVT: RE0F09B]

TRANSAXLE ASSEMBLY

REMOVAL AND INSTALLATION

TRANSAXLE ASSEMBLY

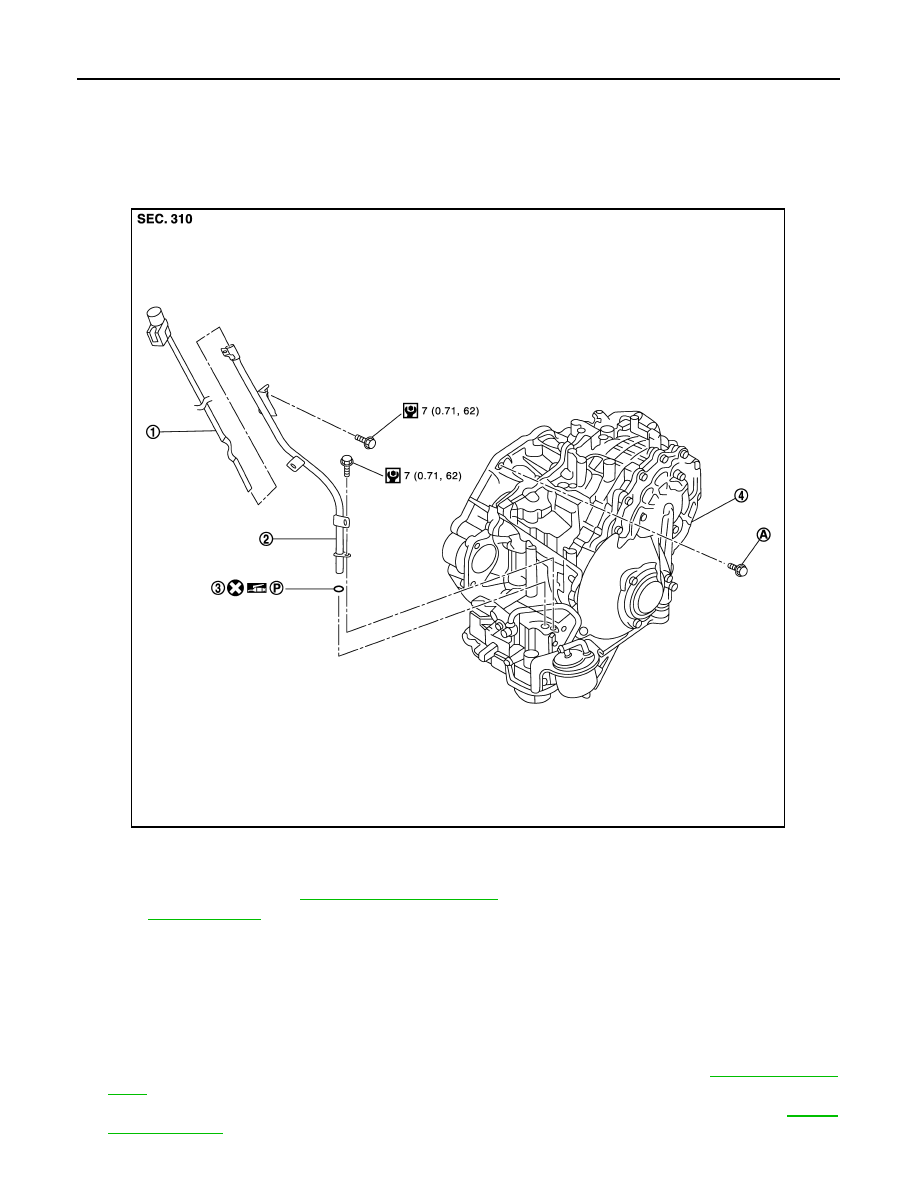

Exploded View

INFOID:0000000003849108

Removal and Installation

INFOID:0000000003849109

WARNING:

Never remove the reservoir tank cap when the engine is hot. Serious burns could occur from high

pressure engine coolant escaping from the reservoir tank.

REMOVAL

1.

Remove the engine, the transaxle assembly and front suspension member. Refer to

.

2.

Lift with hoist and separate engine, transaxle assembly from front suspension member. Refer to

1.

CVT fluid level gauge

2.

CVT fluid charging pipe

3.

O-ring

4.

Transaxle assembly

A.

For tightening torque, refer to

TM-168, "Removal and Installation"

.

for symbols in the figure.

JPDIA0799GB