Content .. 1152 1153 1154 1155 ..

Nissan Teana J32. Manual - part 1154

TM-140

< PREPARATION >

[CVT: RE0F09B]

PREPARATION

PREPARATION

PREPARATION

Special Service Tools

INFOID:0000000003849074

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service Tools

INFOID:0000000003849075

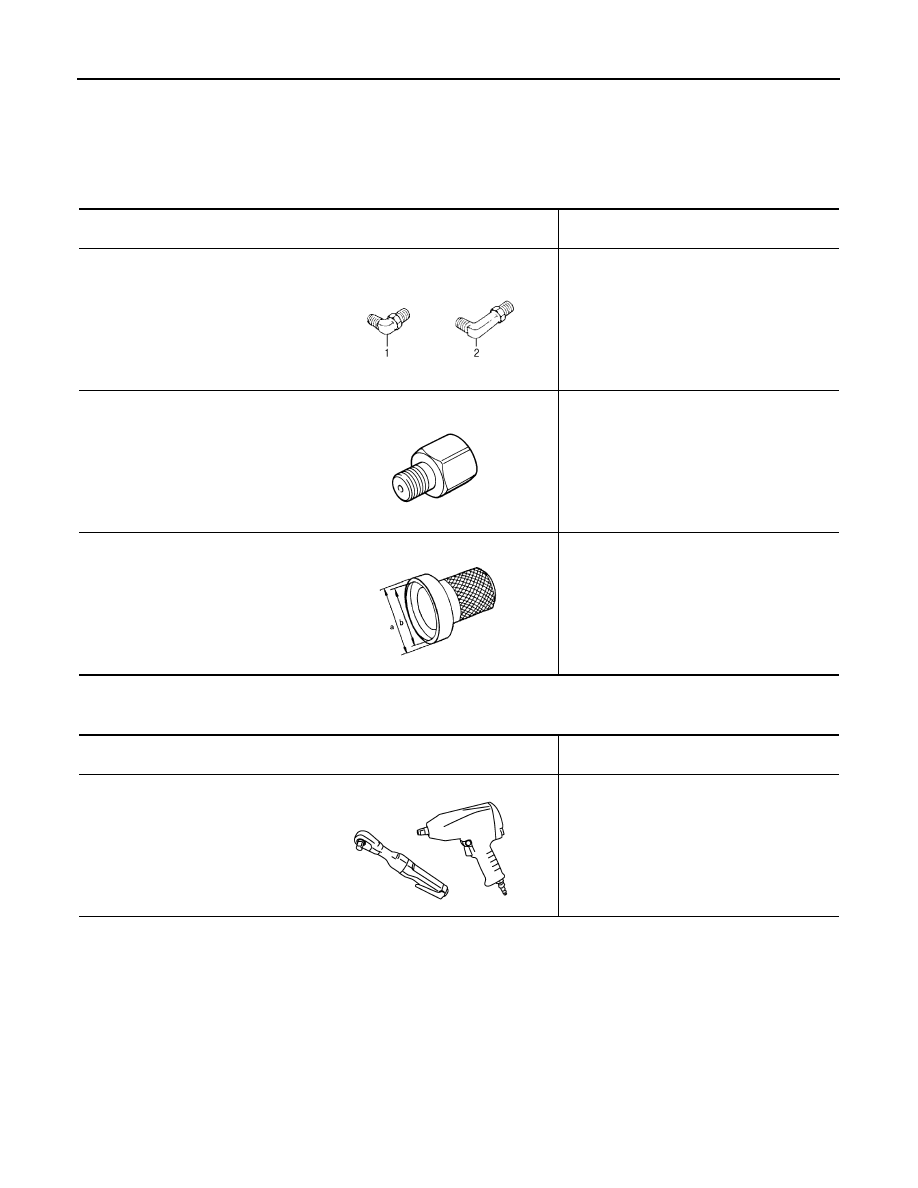

Tool number

Tool name

Description

1. ST25054000

Adapter

2. ST25055000

Adapter

Measuring line pressure

KV31103600

Joint pipe adapter

(With ST25054000)

Measuring line pressure

ST33400001

Drift

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

Installing differential side oil seal

SCIA8372J

ZZA1227D

ZZA0814D

Tool number

Tool name

Description

Power tool

Loosening nuts and bolts

PBIC0190E