содержание .. 861 862 863 864 ..

Nissan Murano Z51. Manual - part 863

A/C AUTO AMP.

HAC-107

< ECU DIAGNOSIS INFORMATION >

[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

*: Perform self-diagnosis under sunshine. When performing indoors, aim a light (more than 60 W) at sunload sensor, otherwise self-diag-

nosis indicates even though the sunload sensor is functioning normally.

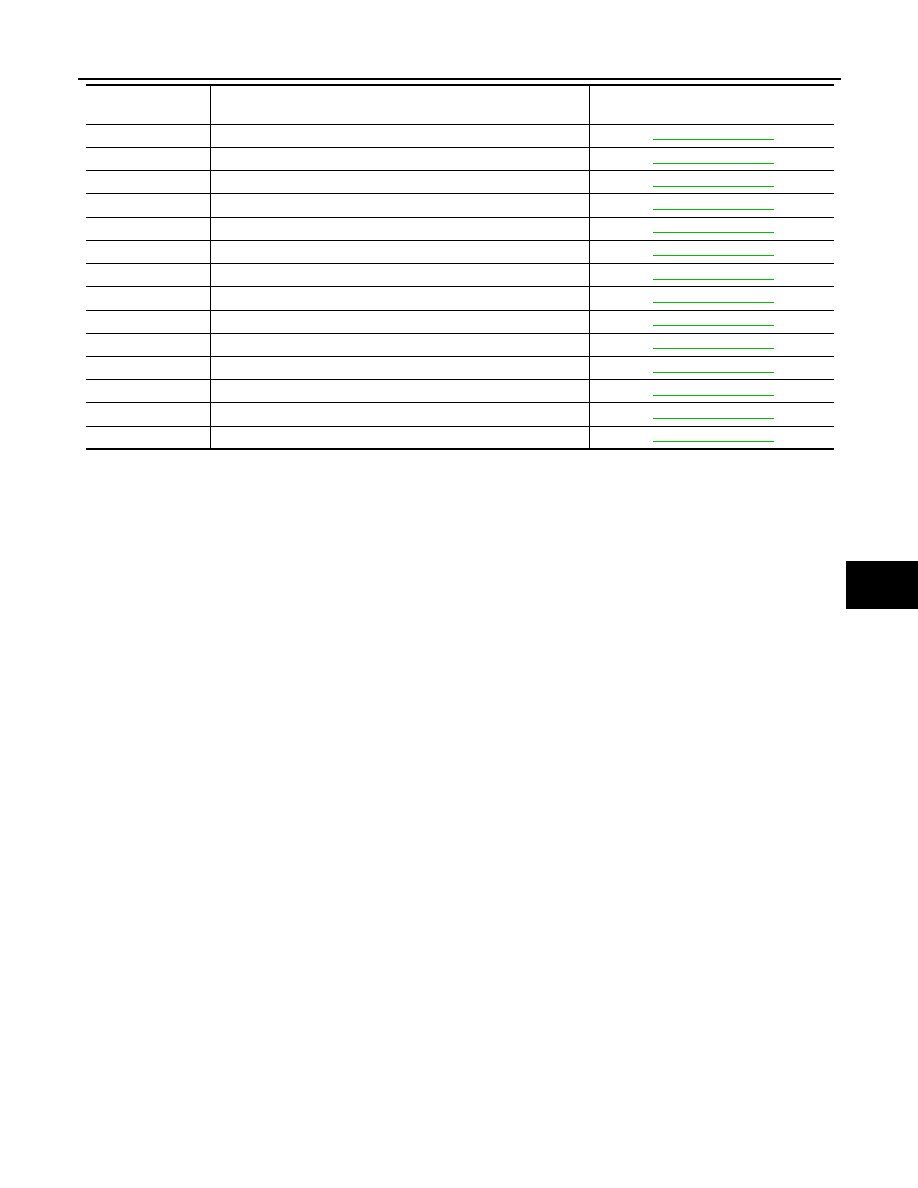

B2634

PASS AIRMIX ACTR SHORT

B2635

PASS AIRMIX ACTR OPEN

B2636

DR VENT DOOR FAIL

B2637

DR B/L DOOR FAIL

B2638

DR D/F1 DOOR FAIL

B2639

DR DEF DOOR FAIL

B263D

FRE DOOR FAIL

B263E

20P FRE DOOR FAIL

B263F

REC DOOR FAIL

B2654

D/F2 DOOR FAIL

B2655

B/L2 DOOR FAIL

B2661

UPPER VENT DOOR OPEN POSI FAIL

B2662

UPPER VENT DOOR MID POSI FAIL

B2663

UPPER VENT DOOR SHUT POSI FAIL

DTC

Items

(CONSULT-III screen terms)

Reference