содержание .. 574 575 576 577 ..

Nissan Murano Z51. Manual - part 576

EC-312

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

P0455 EVAP CONTROL SYSTEM

EC-232, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 15.

NO

>> Replace fuel level sensor unit.

15.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-296, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 16.

NO

>> Replace EVAP control system pressure sensor.

16.

CHECK EVAP/ORVR LINE

Check EVAP/ORVR line between EVAP canister and fuel tank for clogging, kinks, looseness and improper

connection. For location, refer to

.

Is the inspection result normal?

YES

>> GO TO 17.

NO

>> Repair or replace hoses and tubes.

17.

CHECK RECIRCULATION LINE

Check recirculation line between filler neck tube and fuel tank for clogging, kinks, cracks, looseness and

improper connection.

Is the inspection result normal?

YES

>> GO TO 18.

NO

>> Repair or replace hose, tube or filler neck tube.

18.

CHECK REFUELING EVAP VAPOR CUT VALVE

EC-454, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 19.

NO

>> Replace refueling EVAP vapor cut valve with fuel tank.

19.

CHECK INTERMITTENT INCIDENT

GI-39, "Intermittent Incident"

>> INSPECTION END

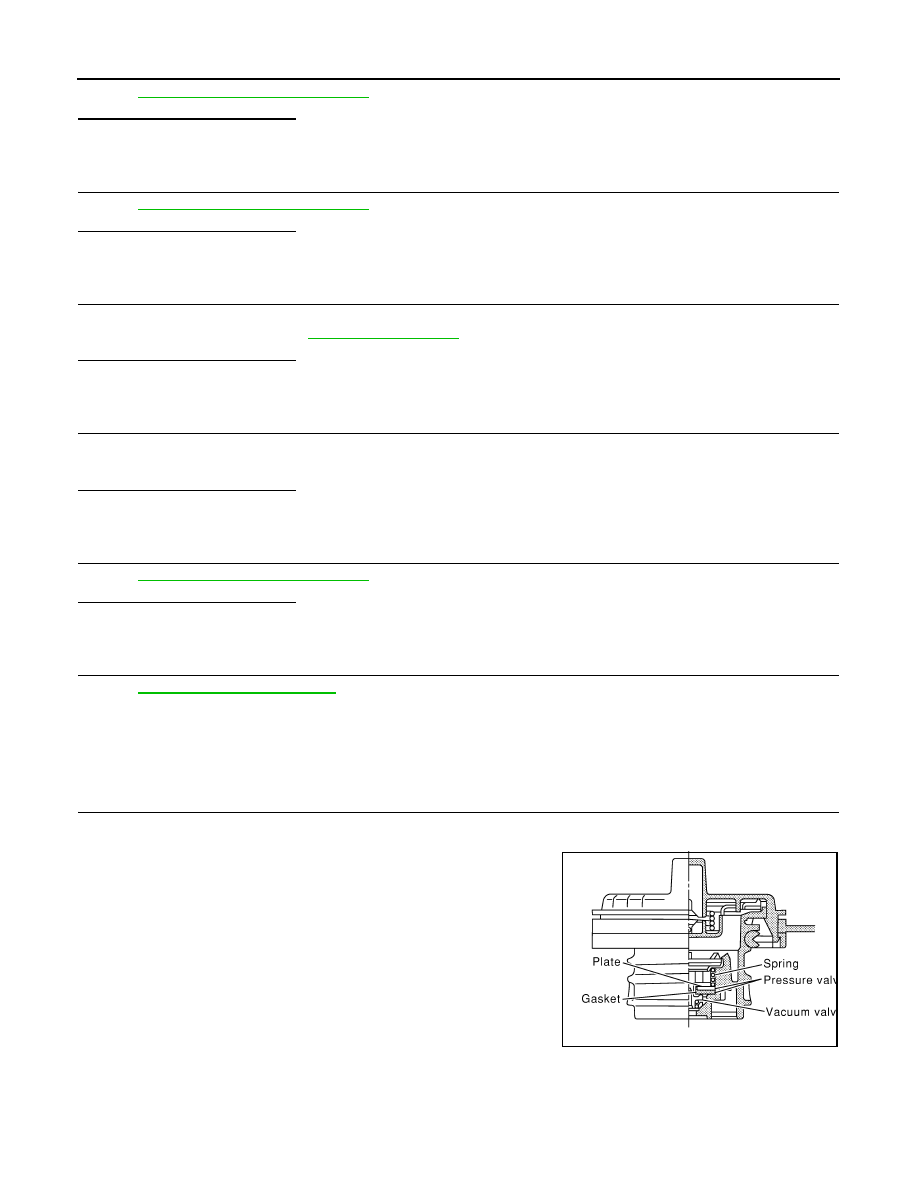

Component Inspection

INFOID:0000000005536700

1.

CHECK FUEL FILLER CAP

1.

Turn ignition switch OFF.

2.

Remove fuel filler cap.

3.

Wipe clean valve housing.

4.

Install fuel filler cap adapter (commercial service tool) to fuel filler cap.

SEF445Y