содержание .. 572 573 574 575 ..

Nissan Murano Z51. Manual - part 574

EC-304

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> GO TO 5.

5.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors B4, E104

• Harness for open or short between EVAP control system pressure sensor and ECM

>> Repair open circuit.

6.

CHECK SENSOR POWER SUPPLY CIRCUIT

Check harness for short to power and short to ground, between the following terminals.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Repair short to ground or short to power in harness or connectors.

7.

CHECK COMPONENTS

Check the following.

• Crankshaft position sensor (POS) (Refer to

EC-257, "Component Inspection"

• Refrigerant pressure sensor (Refer to

.)

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Replace malfunctioning components.

8.

CHECK APP SENSOR

EC-409, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 15.

NO

>> GO TO 9.

9.

REPLACE ACCELERATOR PEDAL ASSEMBLY

1.

Replace accelerator pedal assembly.

2.

EC-409, "Special Repair Requirement"

>> INSPECTION END

10.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND

SHORT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between EVAP control system pressure sensor harness connector and ECM har-

ness connector.

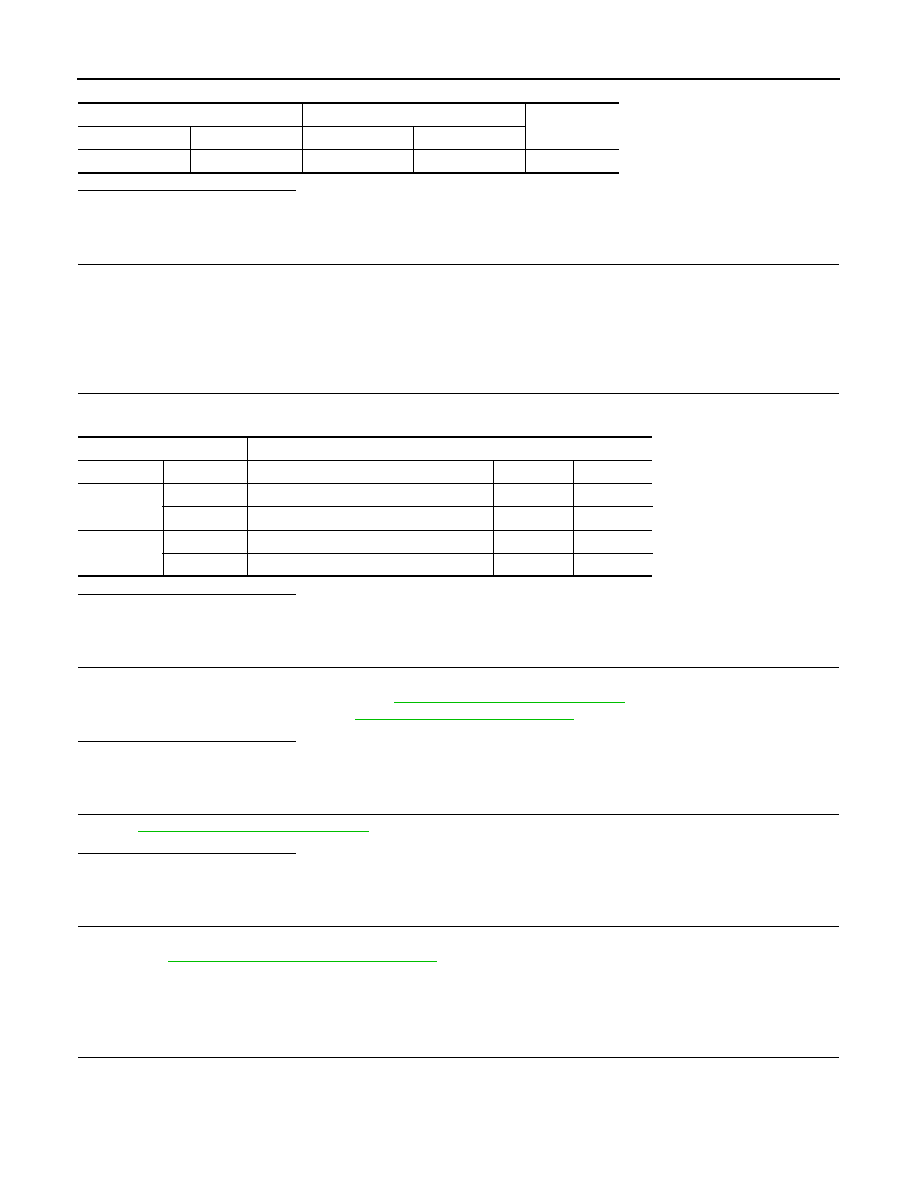

EVAP control system pressure sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

B17

3

E16

91

Existed

ECM

Sensor

Connector

Terminal

Name

Connector

Terminal

F8

72

Refrigerant pressure sensor

E300

1

76

CKP sensor (POS)

F20

1

E16

87

APP sensor

E110

5

91

EVAP control system pressure sensor

B17

3