содержание .. 1445 1446 1447 1448 ..

Nissan Murano Z51. Manual - part 1447

PRECAUTIONS

TM-139

< PRECAUTION >

[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

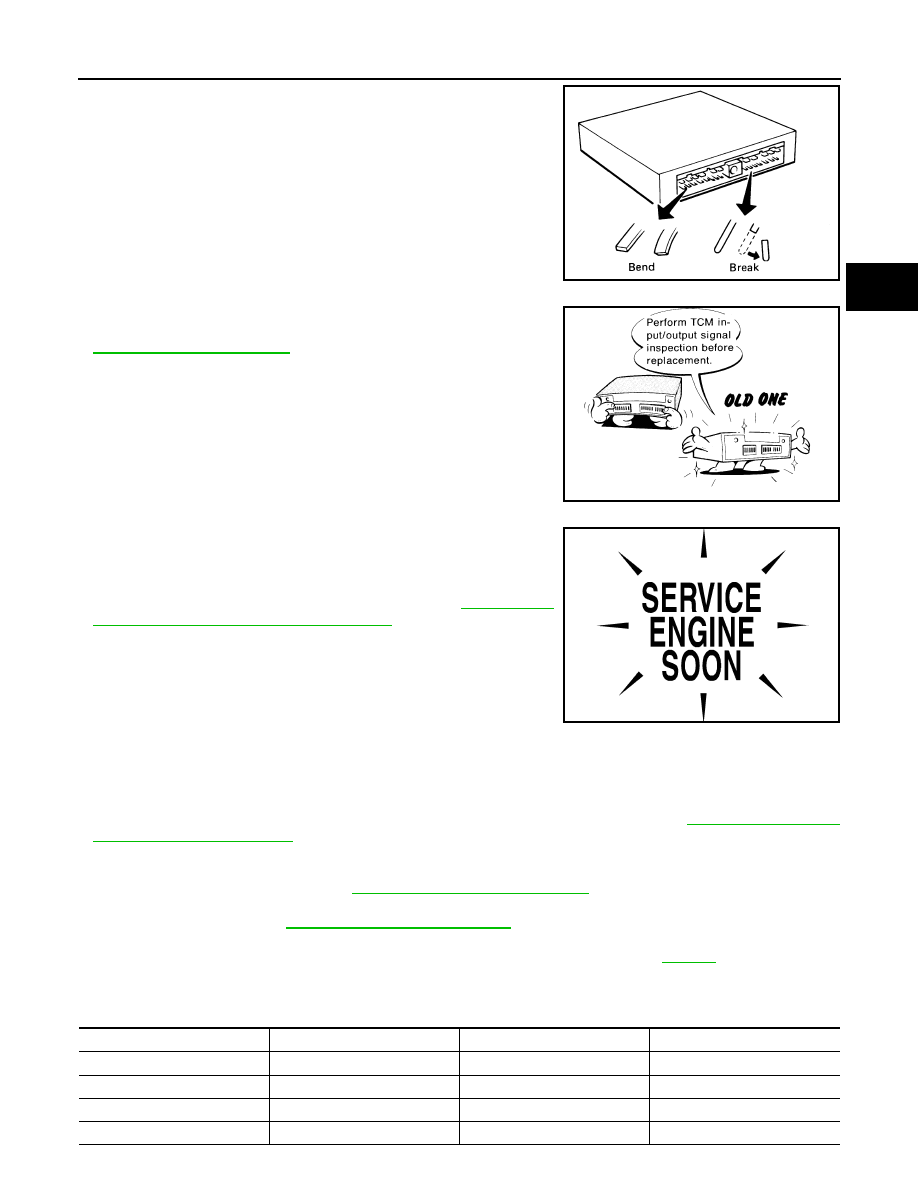

• When connecting or disconnecting pin connectors into or

from TCM, do not damage pin terminals (bend or break).

Check that there are not any bends or breaks on TCM pin ter-

minal, when connecting pin connectors.

• Perform TCM input/output signal inspection and check

whether TCM functions normally or not before replacing TCM.

.

• Perform “DTC Confirmation Procedure” after performing each

TROUBLE DIAGNOSIS.

If the repair is completed the DTC should not be displayed in

the “DTC Confirmation Procedure”.

• Always use the specified brand of CVT fluid. Refer to

NORTH AMERICA : Fluids and Lubricants"

.

• Use lint-free paper, not cloth rags, during work.

• Dispose of the waste oil using the methods prescribed by law, ordi-

nance, etc. after replacing the CVT fluid.

FOR USA AND CANADA : Service Notice or Precaution

INFOID:0000000005514089

OBD-II SELF-DIAGNOSIS

• CVT self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the Malfunction Indicator Lamp (MIL). Refer to the table on

for the indicator used to display each self diagnostic results.

• The self diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure on

TM-34, "Diagnosis Description"

to complete the repair and avoid

unnecessary blinking of the MIL.

For details of OBD-II, refer to

EC-102, "Diagnosis Description"

• Certain systems and components, especially those related to OBD, may use the new style slide-lock-

ing type harness connector. For description and how to disconnect, refer to

FOR USA AND CANADA : ATFTEMP COUNT Conversion Table

INFOID:0000000005514090

SEF291H

MEF040DA

SEF217U

ATFTEMP COUNT

Temperature

°

C (

°

F)

ATFTEMP COUNT

Temperature

°

C (

°

F)

4

–30 (–22)

177

90 (194)

8

–20 (–4)

183

95 (203)

13

–10 (14)

190

100 (212)

17

–5 (23)

196

105 (221)