содержание .. 1435 1436 1437 1438 ..

Nissan Murano Z51. Manual - part 1437

P1778 STEP MOTOR

TM-99

< DTC/CIRCUIT DIAGNOSIS >

[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

P1778 STEP MOTOR

Description

INFOID:0000000005514060

• The step motor changes the step by turning 4 coils ON/OFF according to the signal from TCM. As a result,

the flow of line pressure to primary pulley is changed and pulley ratio is controlled.

• This diagnosis item is detected when the electrical system is OK, but the mechanical system is NG.

• This diagnosis item is detected when the state of the changing of the speed mechanism in the unit does not

operate normally.

DTC Logic

INFOID:0000000005514061

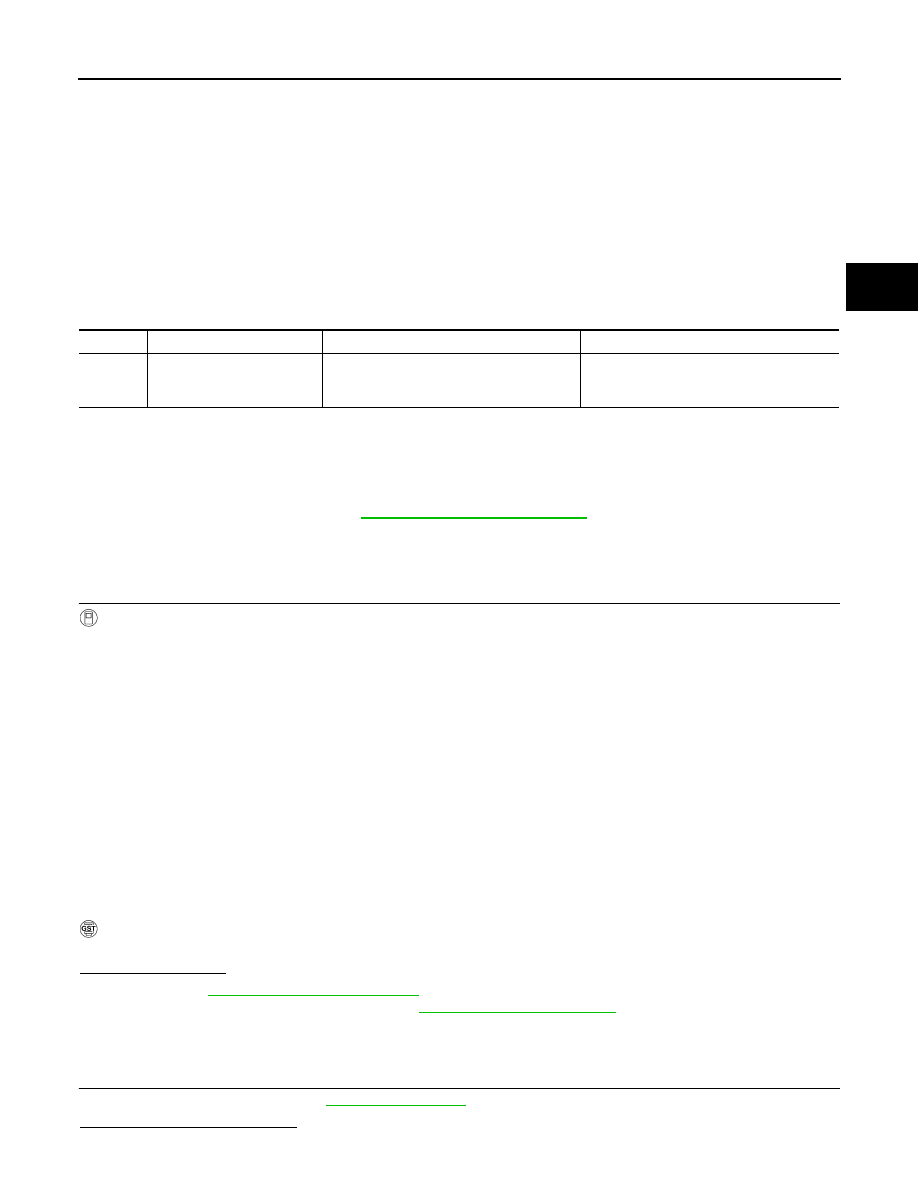

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

• Always drive vehicle at a safe speed.

• Before starting “DTC CONFIRMATION PROCEDURE”, confirm “Hi” or “Mid” or “Low” fixation by

“PRI SPEED” and “VEHICLE SPEED” in “Data Monitor”.

• If hi-geared fixation occurred, go to

NOTE:

Immediately after performing any “DTC CONFIRMATION PROCEDURE”, always turn ignition switch OFF.

Then wait at least 10 seconds before performing the next test.

1.

CHECK DTC DETECTION

With CONSULT-III

1.

Turn ignition switch ON.

2.

Select “Data Monitor” in “TRANSMISSION”.

3.

Make sure that output voltage of CVT fluid temperature sensor is within the range below.

4.

Start engine and maintain the following conditions for at least 30 consecutive seconds.

With GST

Follow the procedure “With CONSULT-III”.

Is “P1778” detected?

YES

>> Go to

NO

>> Check intermittent incident. Refer to

GI-39, "Intermittent Incident"

.

Diagnosis Procedure

INFOID:0000000005514062

1.

CHECK STEP MOTOR SYSTEM

Check step motor system. Refer to

Is the inspection result normal?

DTC

Trouble diagnosis name

DTC is detected if...

Possible cause

P1778

Step Motor Circuit Intermit-

tent

There is a big difference between the num-

ber of steps for the stepping motor and for

the actual gear ratio.

Step motor

ATF TEMP SEN

: 1.0 – 2.0 V

If it is out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to increase the voltage

(cool down the fluid)

Start test from 0 km/h (0 MPH)

Constant acceleration

: Keep 30 seconds or more

VEHICLE SPEED

: 10 km/h (6 MPH) or more

ACC PEDAL OPEN

: More than 1.0/8

RANGE

: “D” position

ENG SPEED

: 450 rpm or more