Murano Cross Cabriolet Z51 (2013 year). Manual - part 107

WT-46

< REMOVAL AND INSTALLATION >

TIRE PRESSURE SENSOR

TIRE PRESSURE SENSOR

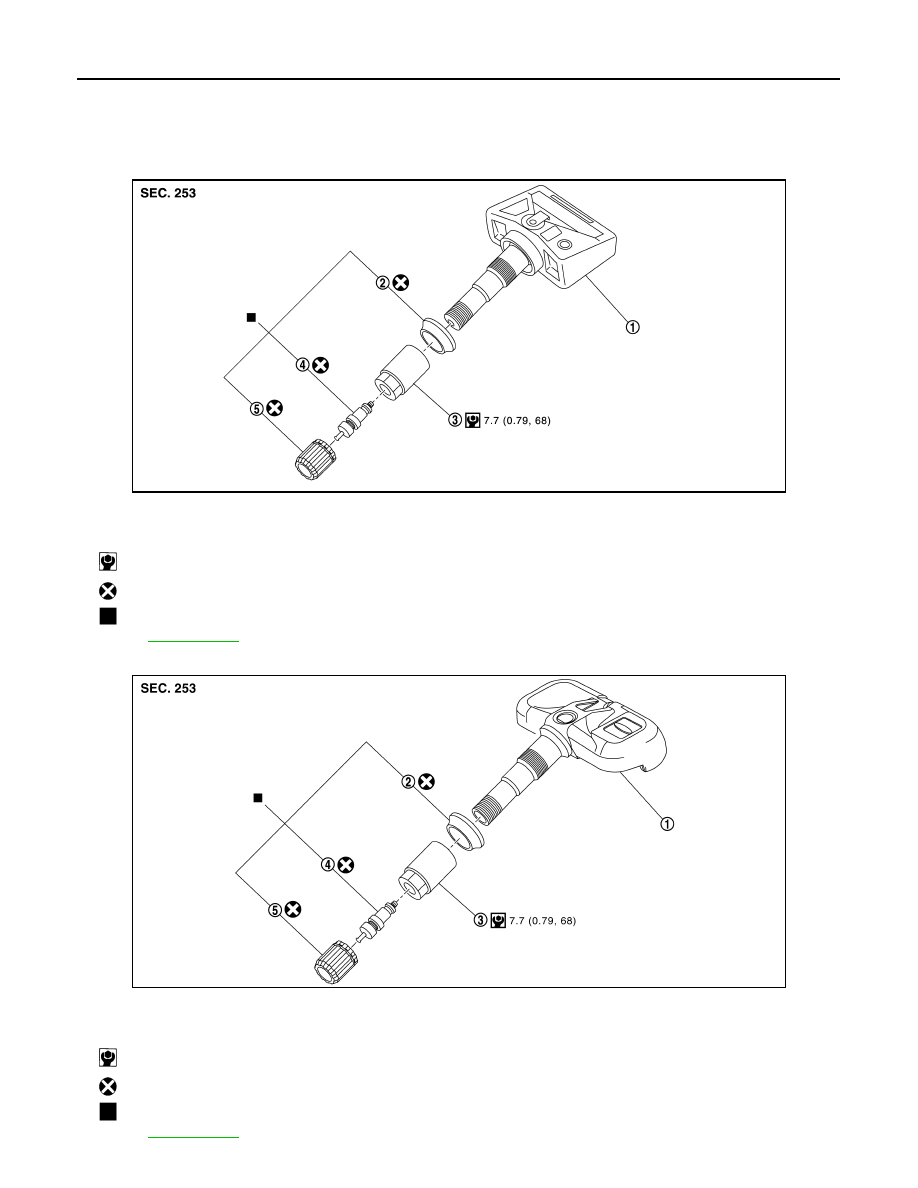

Exploded View

INFOID:0000000008462665

FOR SCHRADER TYPE

FOR PACIFIC TYPE

JSEIA0384GB

1.

Tire pressure sensor

2.

Grommet seal

3.

Valve nut

4.

Valve core

5.

Valve cap

: N·m (kg-m, in-lb)

: Always replace after every disassembly.

: Parts that are replaced as a set when the tire is replaced.

Refer to

for symbols not described above.

JSEIA0572GB

1.

Tire pressure sensor

2.

Grommet seal

3.

Valve nut

4.

Valve core

5.

Valve cap

: N·m (kg-m, in-lb)

: Always replace after every disassembly.

: Parts that are replaced as a set when the tire is replaced.

Refer to

for symbols not described above.

Revision: 2012 October

2013 Murano CrossCabriolet