Murano Cross Cabriolet Z51 (2013 year). Manual - part 56

LAN-18

< BASIC INSPECTION >

[CAN FUNDAMENTAL]

DIAGNOSIS AND REPAIR WORKFLOW

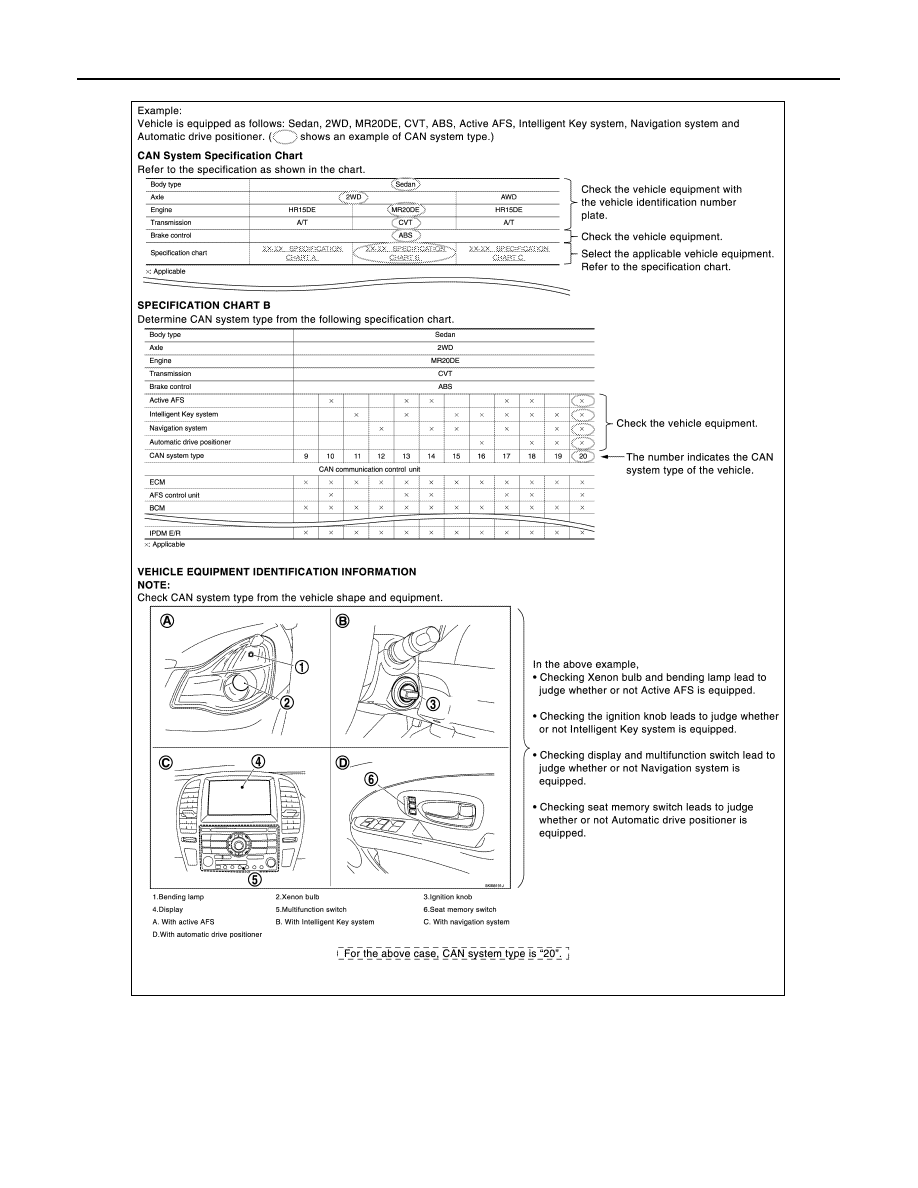

CAN system type is easily checked with the vehicle equipment identification information shown in the chart.

CREATE INTERVIEW SHEET

Fill out the symptom described by the customer, vehicle condition, and CAN system type on the interview

sheet.

JSMIA0530GB

Revision: 2012 October

2013 Murano CrossCabriolet