Nissan Murano Z51 (2013 year). Manual - part 67

REAR LOWER LINK & COIL SPRING

RSU-9

< REMOVAL AND INSTALLATION >

C

D

F

G

H

I

J

K

L

M

A

B

RSU

N

O

P

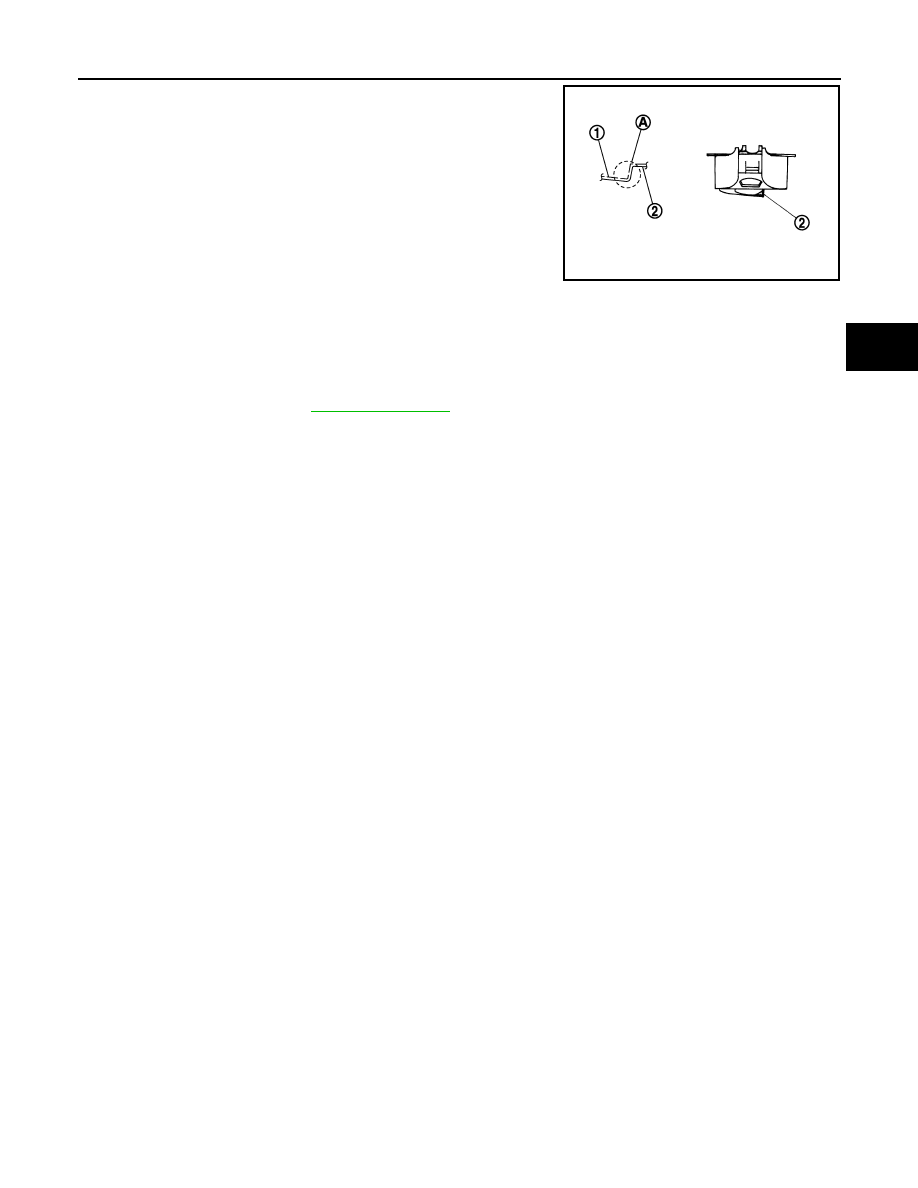

• Install coil spring by aligning lower end of the coil spring to step (A)

between rubber seat (1) and rear lower link (2).

CAUTION:

Set coil spring so that its paint marks are aligned with the

positions of 3.5 turns (2 places) and 4.5 turns (1 place) from

the bottom end of the coil spring.

• Perform the final tightening of rear suspension member and axle

installation position (rubber bushing) under unladen condition with

tires on level ground.

Inspection

INFOID:0000000008459238

INSPECTION AFTER REMOVAL

Check rear lower link, bushing and coil spring for deformation, crack, and damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

Check wheel alignment. Refer to

.

JPEIB0013ZZ

Revision: 2012 September

2013 MURANO