Nissan Murano Z51 (2012 year). Manual - part 53

MIR-28

< ECU DIAGNOSIS INFORMATION >

[WITH ADP]

AUTOMATIC DRIVE POSITIONER CONTROL UNIT

AUTOMATIC DRIVE POSITIONER CONTROL UNIT

Reference Value

INFOID:0000000007687751

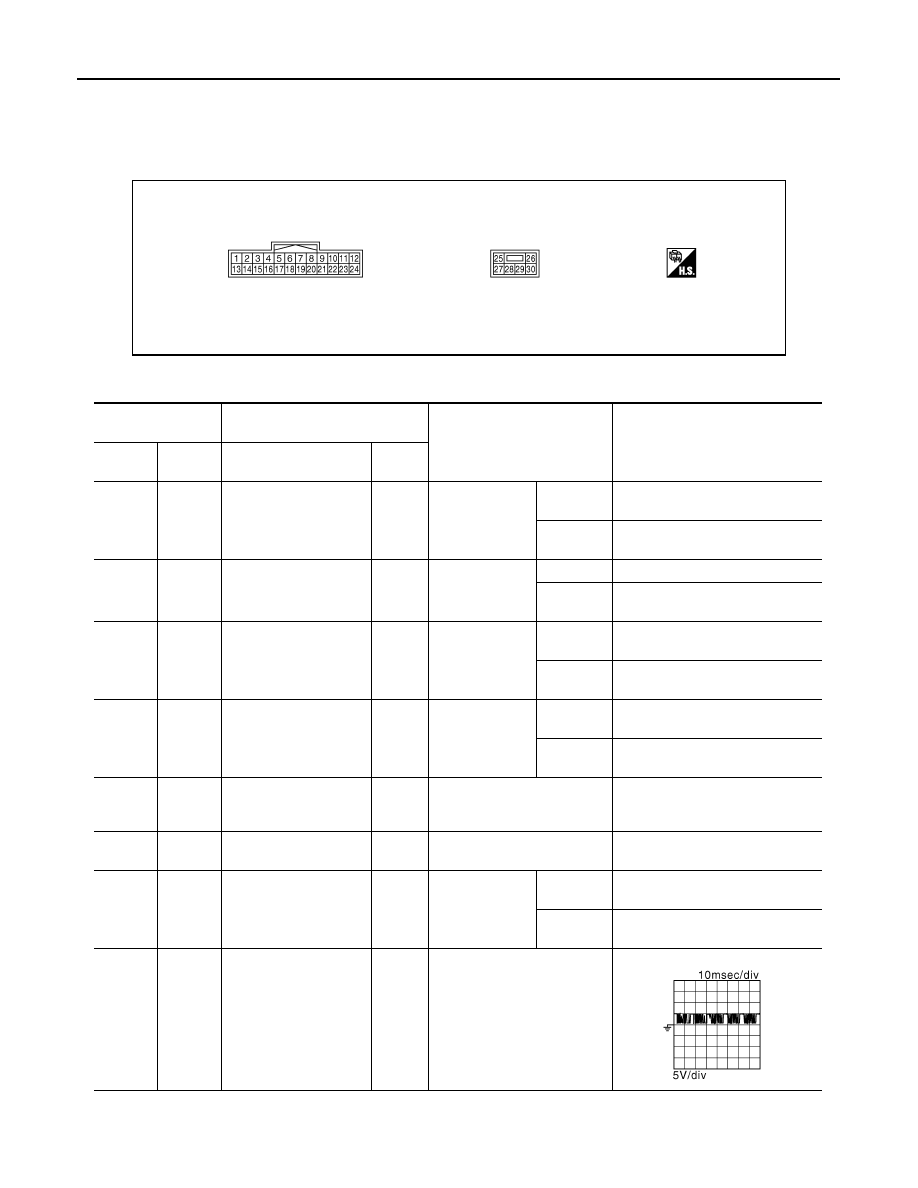

TERMINAL LAYOUT

PHYSICAL VALUES

JMJIA1389ZZ

Terminal No.

(wire color)

Description

Condition

Voltage (V)

(Approx.)

+

-

Signal name

Input/

Output

1

(Y)

Ground

Tilt switch up signal

Input

Tilt switch

Operate

(up)

0

Other than

above

5

2

(GR)

Ground

Changeover switch RH

signal

Input

Changeover

switch position

RH

0

Neutral or

LH

5

3

(SB)

Ground

Mirror switch up signal

Input

Mirror switch

Operated

(up)

0

Other than

above

5

4

(LG)

Ground

Mirror switch left signal

Input

Mirror switch

Operated

(left)

0

Other than

above

5

5

(R)

Ground

Door mirror sensor (pas-

senger side) up/down

signal

Input

Door mirror RH position

Change between 3.4 (close to

peak) 0.6 (close to valley)

6

(Y)

Ground

Door mirror sensor (driv-

er side) up/down signal

Input

Door mirror LH position

Change between 3.4 (close to

peak) 0.6 (close to valley)

7

(P)

Ground

Telescopic switch for-

ward signal

Input

Telescopic

switch

Operate

(forward)

0

Other than

above

5

8

(LG)

Ground

UART communication

(TX/RX)

Output

Ignition switch ON

JMJIA1391ZZ

Revision: 2013 February

2012 MURANO