Nissan Murano Z51 (2011 year). Manual - part 17

WHEEL SENSOR

BRC-119

< REMOVAL AND INSTALLATION >

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

REMOVAL AND INSTALLATION

WHEEL SENSOR

FRONT WHEEL SENSOR

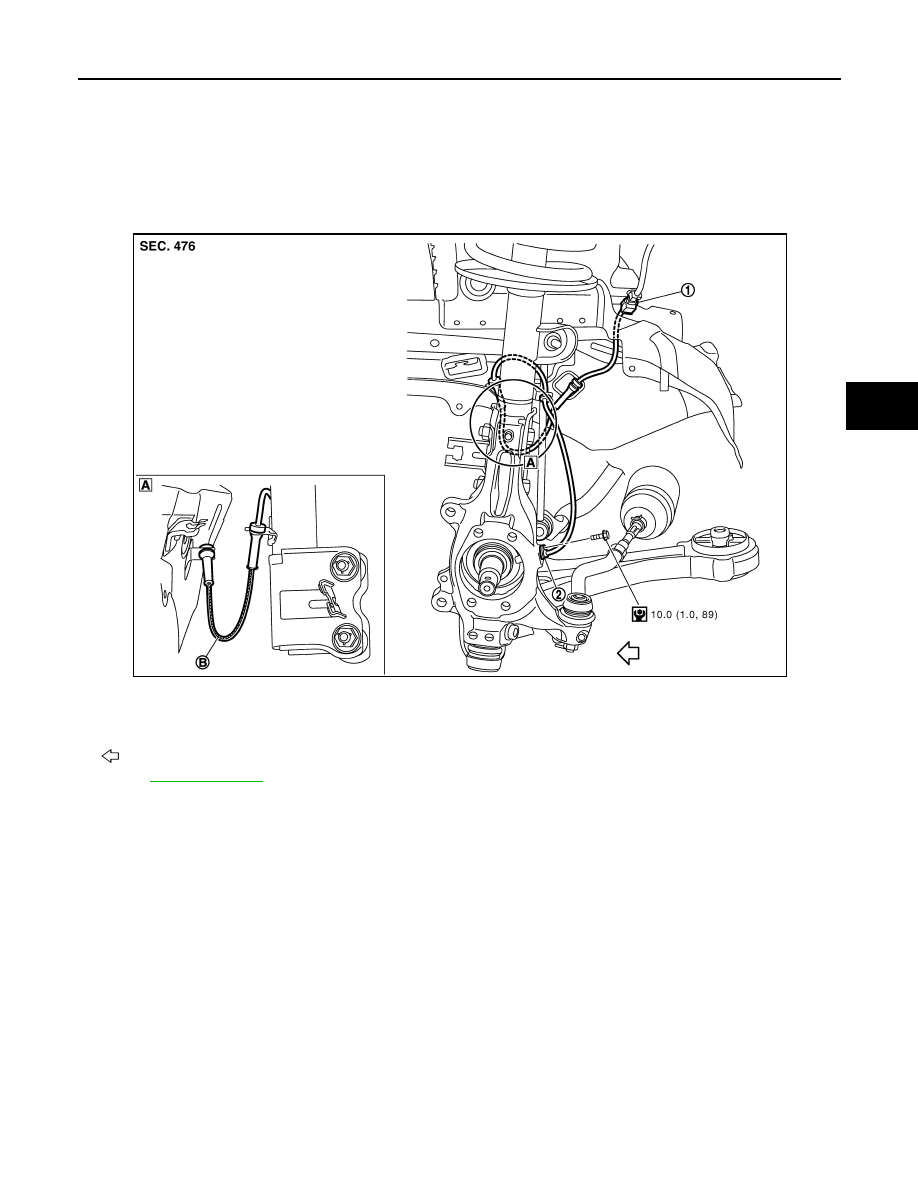

FRONT WHEEL SENSOR : Exploded View

INFOID:0000000006263544

NOTE:

The above figure (front side) shows left side. Right side is the mirror image.

FRONT WHEEL SENSOR : Removal and Installation

INFOID:0000000006263545

REMOVAL

Be careful with the following when removing sensor.

CAUTION:

• Never twist sensor harness as much as possible, when removing it. Pull sensors out without pulling

sensor harness.

• Be careful to avoid damaging sensor edges or rotor teeth. Remove wheel sensor first before remov-

ing front or rear wheel hub. This is to avoid damage to sensor wiring and loss of sensor function.

• When you see the harness of the wheel sensor from the front side of the vehicle ensure that the

white lines (B) are not twisted.

INSTALLATION

Be careful with the following when installing wheel sensor. Tighten installation bolts to the specified torques.

• When installing, make sure there is no foreign material such as iron chips on and in the mounting hole of the

wheel sensor. Make sure no foreign material has been caught in the sensor rotor. Remove any foreign mate-

rial and clean the mount.

1.

Front LH wheel sensor connector

2.

Front LH wheel sensor

B.

White line (slant line)

: Vehicle front

Refer to

JSFIA0190GB

Revision: 2011 November

2011 MURANO