Nissan Murano Z50 (2007 year). Manual - part 35

BODY REPAIR

BL-305

C

D

E

F

G

H

J

K

L

M

A

B

BL

Revision: 2006 July

2007 Murano

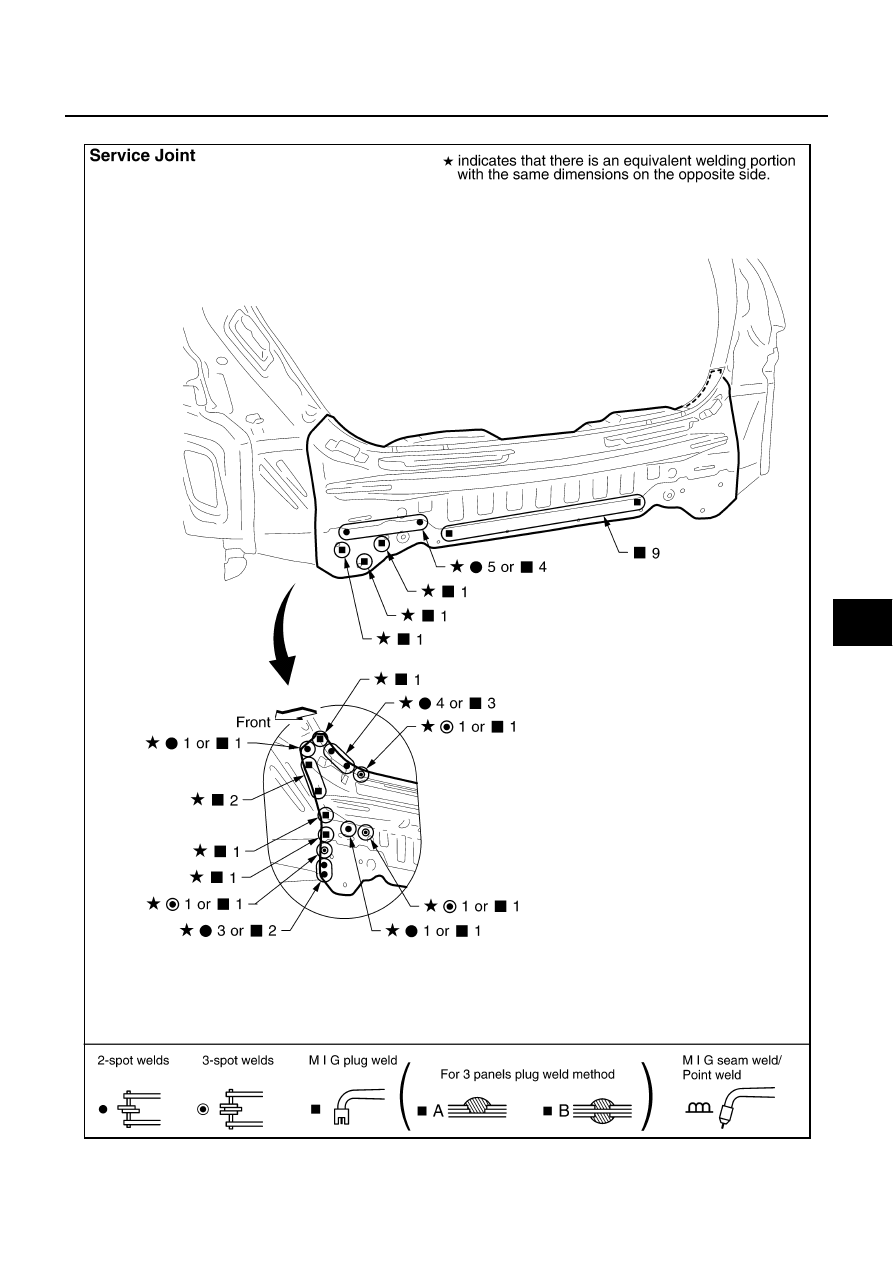

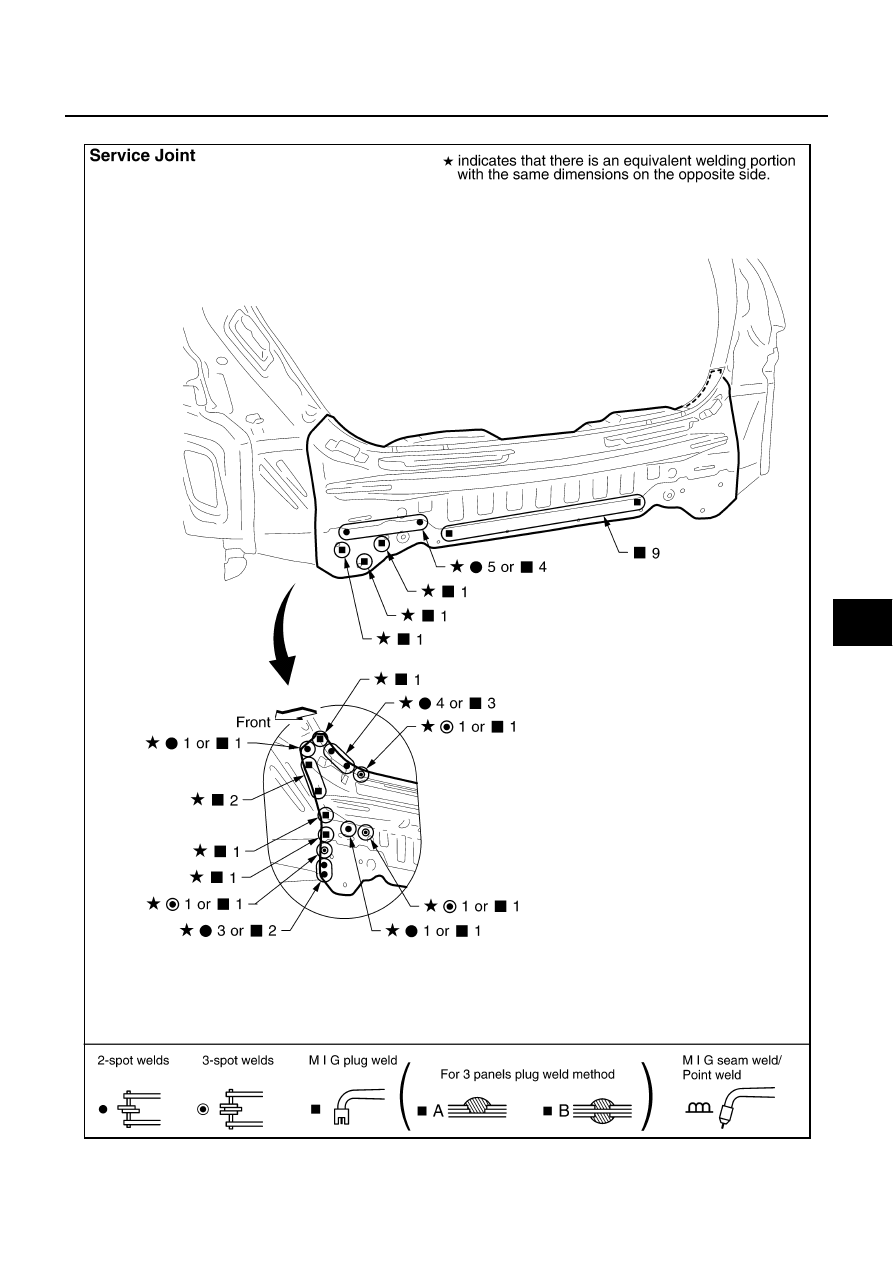

REAR PANEL

Change parts

●

Rear panel assembly

SIIA2192E

|

|

|

BODY REPAIR BL-305 C D E F G H J K L M A B BL Revision: 2006 July 2007 Murano REAR PANEL Change parts ● Rear panel assembly SIIA2192E |