Nissan Murano Z50 (2006 year). Manual - part 187

REAR FINAL DRIVE ASSEMBLY

RFD-29

C

E

F

G

H

I

J

K

L

M

A

B

RFD

Revision: 2006 August

2006 Murano

b.

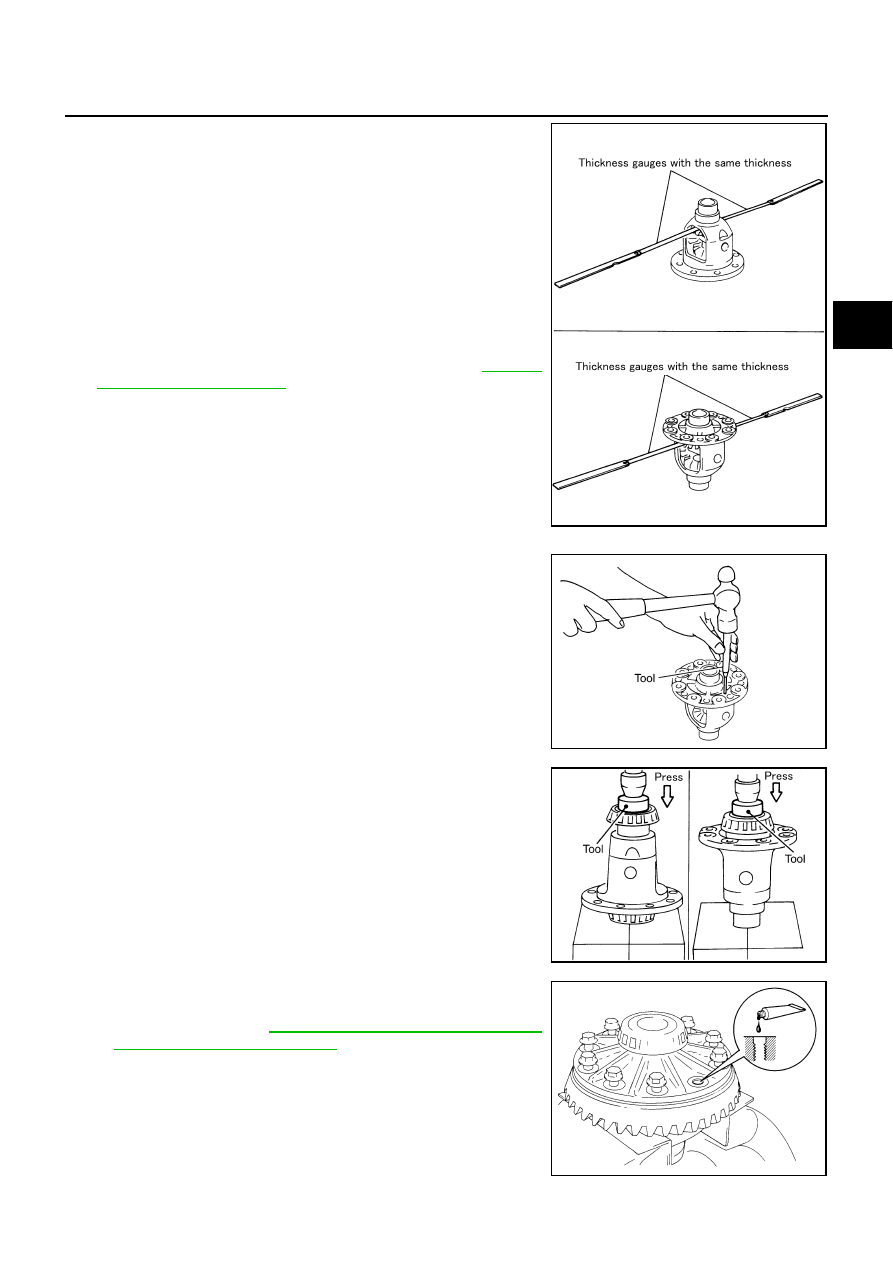

Using thickness gauges, measure the clearance between side

gear back and differential case at 3 different positions, while

rotating side gear. Average the 3 readings, and then measure

the clearance. (Measure the clearance of the other side as well.)

CAUTION:

To prevent side gear from tilting, insert thickness gauges

with the same thickness from both sides.

c.

If the back clearance is outside the specification, use a thicker/

thinner side gear thrust washer to adjust. Refer to

.

CAUTION:

Select a side gear thrust washer for right and left individu-

ally.

6.

Drive a lock pin into pinion mating shaft, using the pin punch.

CAUTION:

Do not reuse lock pin.

7.

Press side bearing inner races to differential case, using the

drift.

CAUTION:

Do not reuse side bearing inner race.

8.

Apply thread locking sealant into the thread hole of drive gear.

●

Use Genuine Medium Strength Thread Locking Sealant or

equivalent. Refer to

CAUTION:

The drive gear back and threaded holes shall be cleaned

and decreased sufficiently.

Side gear back clearance specification:

0.2 mm (0.008 in) or less.

(Each gear should rotate smoothly without excessive

resistance during differential motion.)

When the back clearance is large:

Use a thicker thrust washer.

When the back clearance is small:

Use a thinner thrust washer.

Tool number

: ST23550000 (

—

)

SDIA0583E

PDIA0062E

Tool number

: KV40105020 (

—

)

PDIA0052E

SPD554