Nissan Murano Z50 (2006 year). Manual - part 85

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-139

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2006 August

2006 Murano

20.

CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1”, “A/F ALPHA-B2”, and “B/FUEL SCHDL” in “DATA MONITOR (SPEC)” mode, and

make sure that the each indication is within the SP value.

OK or NG

OK

>> INSPECTION END

NG (“B/FUEL SCHDL” is more, “A/F ALPHA-B1”, “A/F ALPHA-B2” are less than the SP value)>>GO TO 21.

21.

DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

1.

Stop the engine.

2.

Disconnect mass air flow sensor harness connector. Check pin terminal and connector for damage and

then reconnect it again.

>> GO TO 22.

22.

CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1.

Start engine.

2.

Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “DATA MONITOR (SPEC)” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK

>> 1. Detect malfunctioning part of mass air flow sensor circuit and repair it. Refer to

2. GO TO 29.

NG

>> GO TO 23.

23.

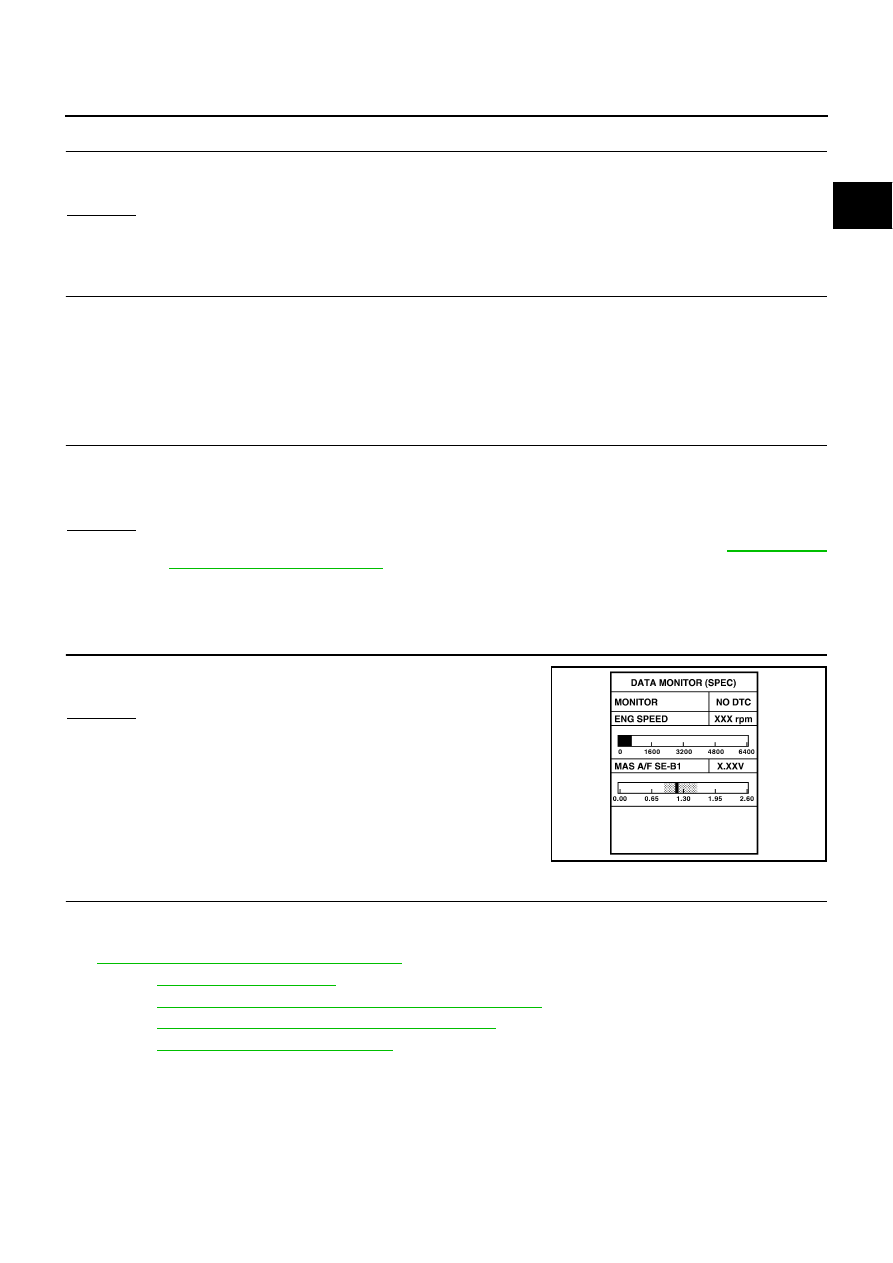

CHECK “MAS A/F SE-B1”

Select “MAS A/F SE-B1” in “DATA MONITOR (SPEC)” mode, and

make sure that the indication is within the SP value.

OK or NG

OK

>> GO TO 24.

NG (More than the SP value)>>Replace mass air flow sensor, and

then GO TO 29.

24.

REPLACE ECM

1.

Replace ECM.

2.

Perform initialization of NVIS(NATS) system and registration of all NVIS(NATS) ignition key IDs. Refer to

BL-238, "ECM Re-communicating Function"

.

3.

Perform

.

4.

Perform

EC-75, "Accelerator Pedal Released Position Learning"

5.

Perform

EC-76, "Throttle Valve Closed Position Learning"

6.

Perform

EC-76, "Idle Air Volume Learning"

>> GO TO 29.

PBIB2370E