Nissan Murano Z50 (2005 year). Manual - part 204

SUNROOF

RF-45

C

D

E

F

G

H

J

K

L

M

A

B

RF

Revision: 2005 August

2005 Murano

CAUTION:

●

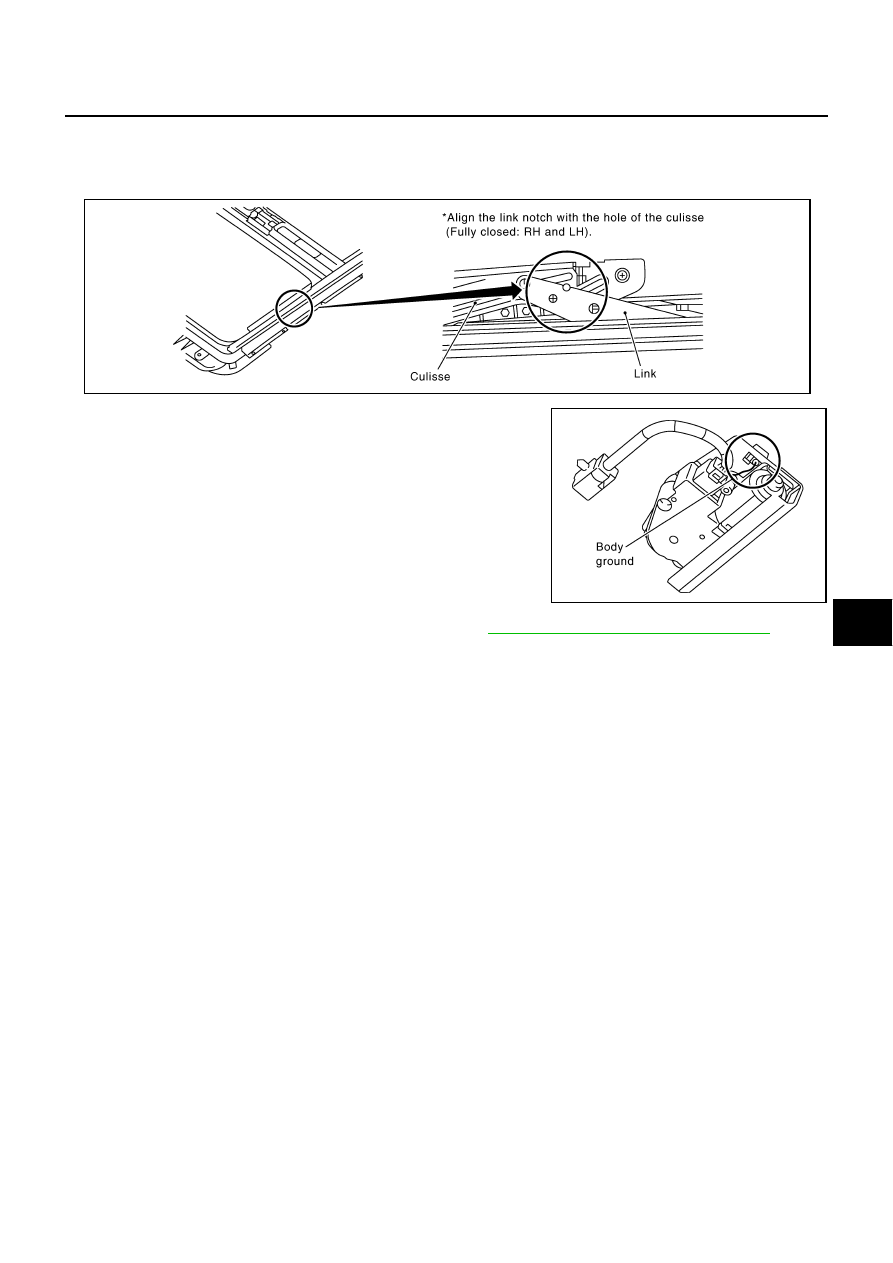

Before installing the sunroof motor assembly, be sure to place the link and wire assembly in the

symmetrical and fully closed position.

●

Align the link notch with the hole of the culisse (fully closed : RH and LH).

2.

Confirm the body ground of the noise cover is connected.

3.

Initialization it after installing the sunroof motor. Refer to

RF-12, "INITIALIZATION PROCEDURE"

.

PIIA5062E

PIIA5063E