Nissan Murano Z50 (2005 year). Manual - part 205

REAR FINAL DRIVE ASSEMBLY

RFD-15

C

E

F

G

H

I

J

K

L

M

A

B

RFD

Revision: 2005 August

2005 Murano

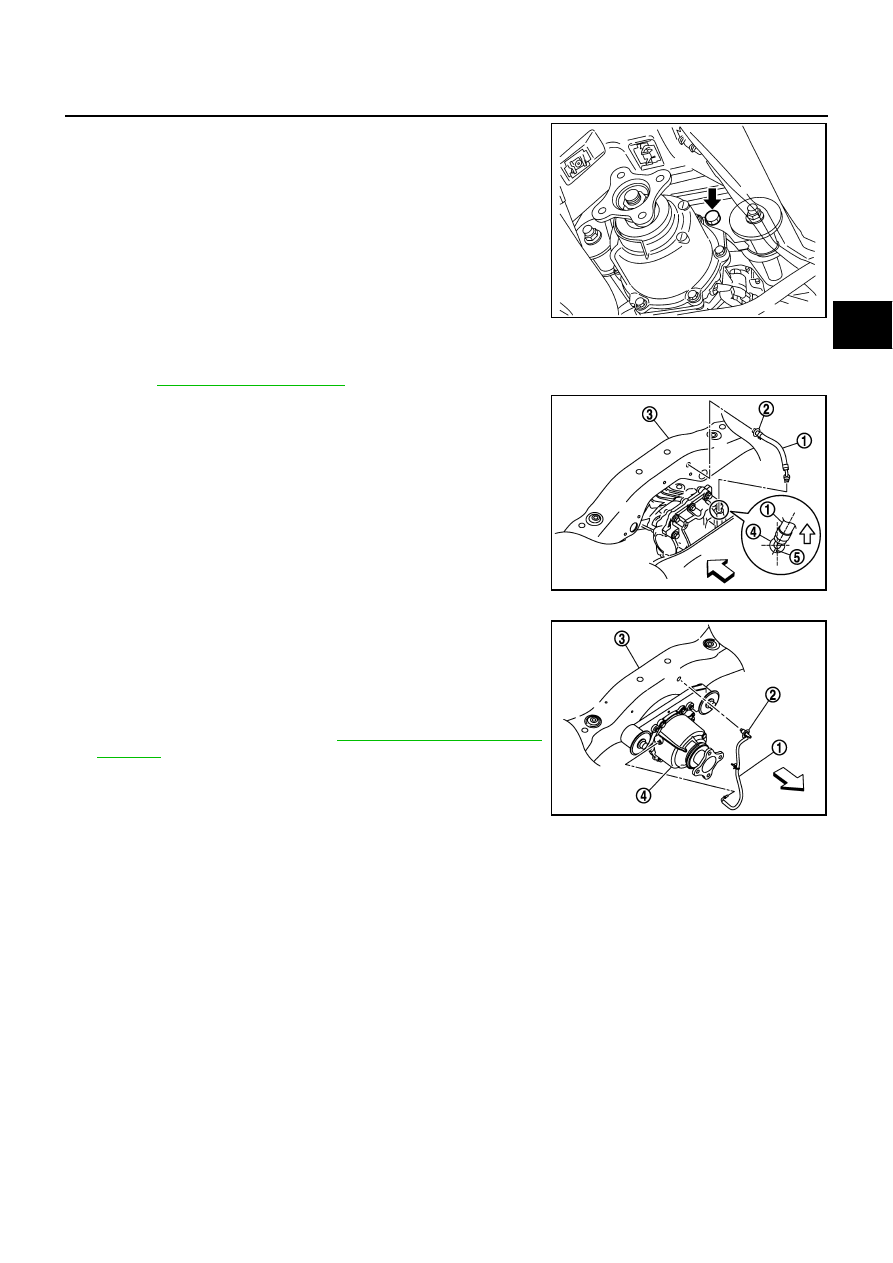

8.

Remove rear final drive mounting bolts at final drive mounting

bracket with power tool, and then remove rear final drive assem-

bly.

If necessary, remove final drive mounting bracket.

CAUTION:

Secure rear final drive assembly to a suitable jack while

removing it.

INSTALLATION

Note the following, and install in the reverse order of removal.

●

Refer to

about each tightening torque.

●

When installing breather hoses, refer to the figure and following.

CAUTION:

Make sure there are no pinched or restricted areas on the

breather hose caused by bending or winding when install-

ing it.

–

For installation of rear final drive breather hose (1), the vehicle

side end breather connector (2) shall be inserted to rear suspen-

sion member (3). Install metal connector (4) side of this hose to

rear cover by inserting it with aiming painted marking (5) to the

rear of vehicle.

CAUTION:

Do not reuse breather connector.

–

For installation of electric controlled coupling breather hose (1),

the vehicle side end breather connector (2) shall be inserted to

rear suspension member (3). Install its metal tube to rear final

drive assembly (4) and direct the metal tube hose side end to

the front of vehicle.

●

When oil leaks while removing final drive assembly, check oil

level after the installation. Refer to

.

CAUTION:

Do not reuse breather connector.

PDIA0040E

PDIA1104E

PDIA1105E