Nissan Murano Z50 (2005 year). Manual - part 198

REAR PROPELLER SHAFT

PR-7

C

E

F

G

H

I

J

K

L

M

A

B

PR

Revision: 2005 August

2005 Murano

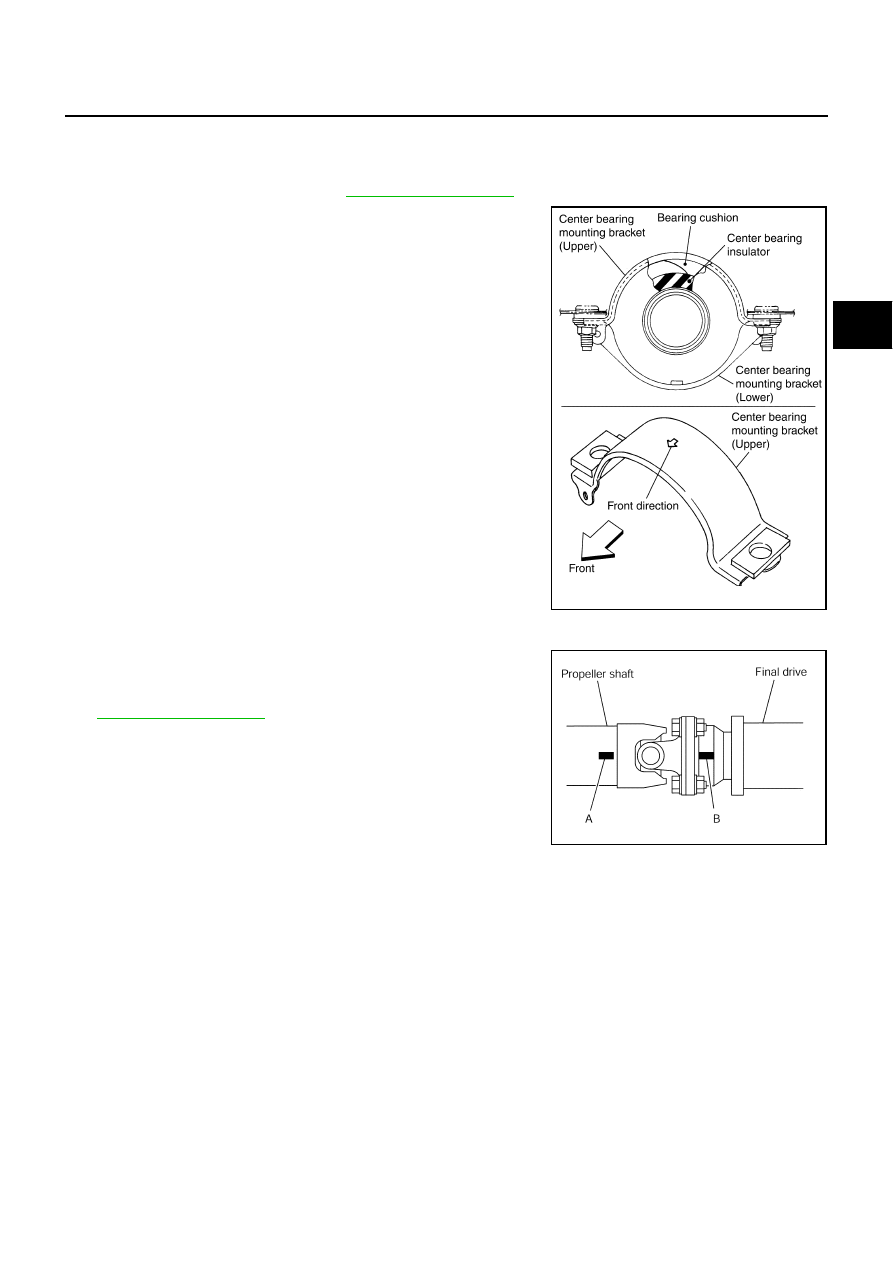

INSTALLATION

Note the following, and install in the reverse order of removal.

●

Align matching marks to install propeller shaft to final drive and transfer companion flanges, and then

tighten to specified torque. Refer to

●

Adjust position of mounting bracket sliding back and forth to pre-

vent play in thrust direction of center bearing insulator. Install

bracket to vehicle.

●

After assembly, perform a driving test to check propeller shaft

vibration. If vibration occurred, separate propeller shaft from

final drive or transfer. Reinstall companion flange after rotating it

by 90, 180, 270 degrees. Then perform driving test and check

propeller shaft vibration again at each point.

●

If propeller shaft or final drive has been replaced, install them as follows;

1.

Install propeller shaft while aligning its matching mark A with the

matching mark B on the joint as close as possible.

2.

Tighten fixing bolts and nuts to the specified torque. Refer to

PDIA0017E

PDIA0423E