Nissan Murano Z50 (2005 year). Manual - part 199

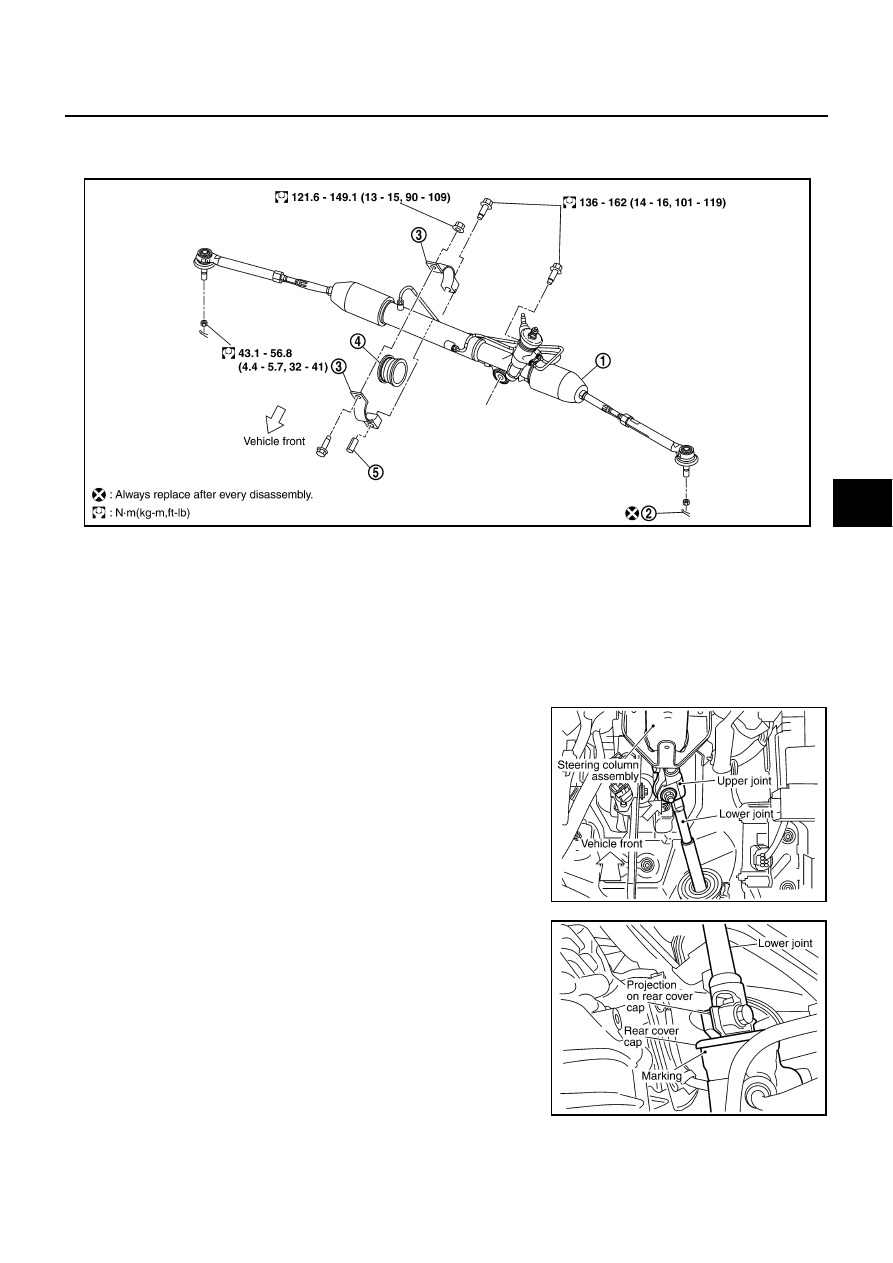

POWER STEERING GEAR AND LINKAGE

PS-15

C

D

E

F

H

I

J

K

L

M

A

B

PS

Revision: 2005 August

2005 Murano

POWER STEERING GEAR AND LINKAGE

PFP:49001

Removal and Installation

AGS000CO

CAUTION:

Spiral cable may snap due to steering operation if steering column is separated from steering gear

assembly. Therefore fix steering wheel with a string to avoid turns.

REMOVAL

2WD

1.

Set wheels in the straight-ahead position.

2.

Remove lock nut and bolt, then separate lower joint from upper

joint.

3.

Remove tires from vehicle with power tool.

4.

Confirm slit of lower joint fits with the projection on rear cover

cap, furthermore marking position on steering gear assembly

nearly fits with the projection on rear cover cap.

5.

Remove cotter pin at steering knuckle, then loosen mounting

nut.

1.

Steering gear assembly

2.

Cotter pin

3.

Rack mounting bracket

4.

Rack mounting insulator

5.

Sleeve

SGIA0486E

SGIA0471E

SGIA0487E