Nissan Murano Z50 (2004 year). Manual - part 178

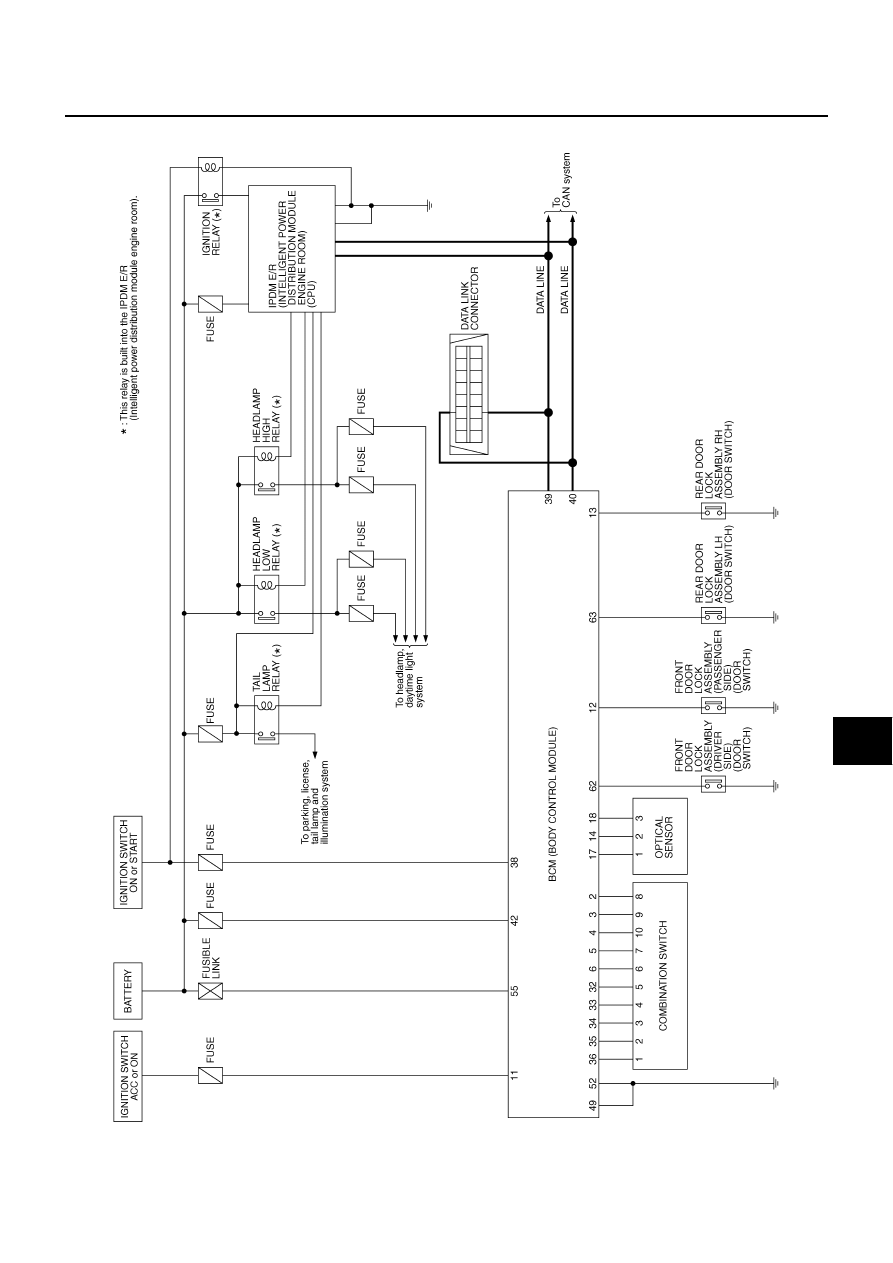

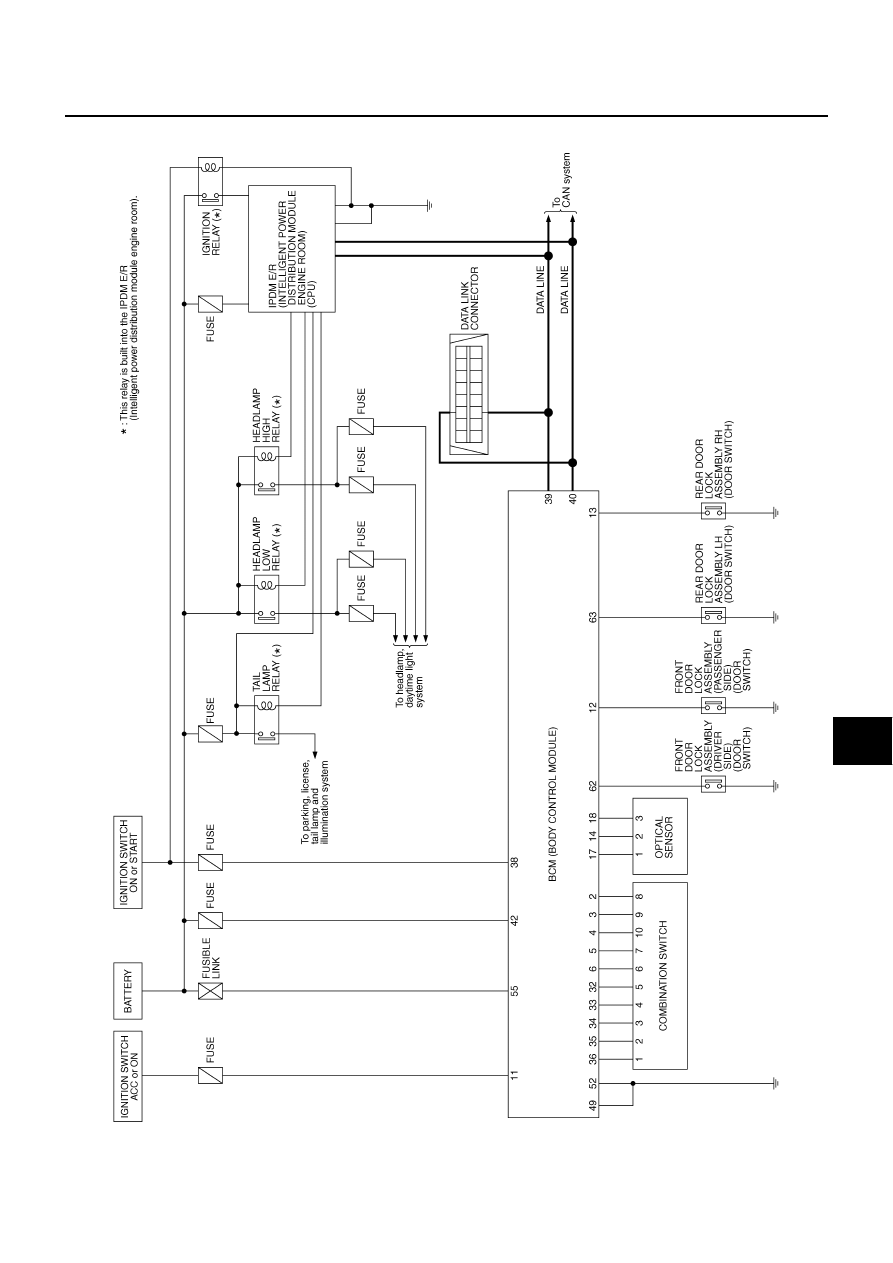

AUTO LIGHT SYSTEM

LT-89

C

D

E

F

G

H

I

J

L

M

A

B

LT

Revision: 2004 November

2004 Murano

Schematic

AKS004JM

TKWA1683E

|

|

|

AUTO LIGHT SYSTEM LT-89 C D E F G H I J L M A B LT Revision: 2004 November 2004 Murano Schematic AKS004JM TKWA1683E |