Nissan Murano Z50 (2004 year). Manual - part 176

HEADLAMP -CONVENTIONAL TYPE-

LT-57

C

D

E

F

G

H

I

J

L

M

A

B

LT

Revision: 2004 November

2004 Murano

High Beam Indicator Lamp Does Not Illuminate

AKS00AKI

1.

CHECK BULB

Check bulb of high beam indicator lamp.

OK or NG

OK

>> Replace combination meter.

NG

>> Replace indicator bulb.

Headlamp Low Beam Does Not Illuminate (Both Sides)

AKS00AKJ

1.

CHECK COMBINATION SWITCH INPUT SIGNAL

With CONSULT-II

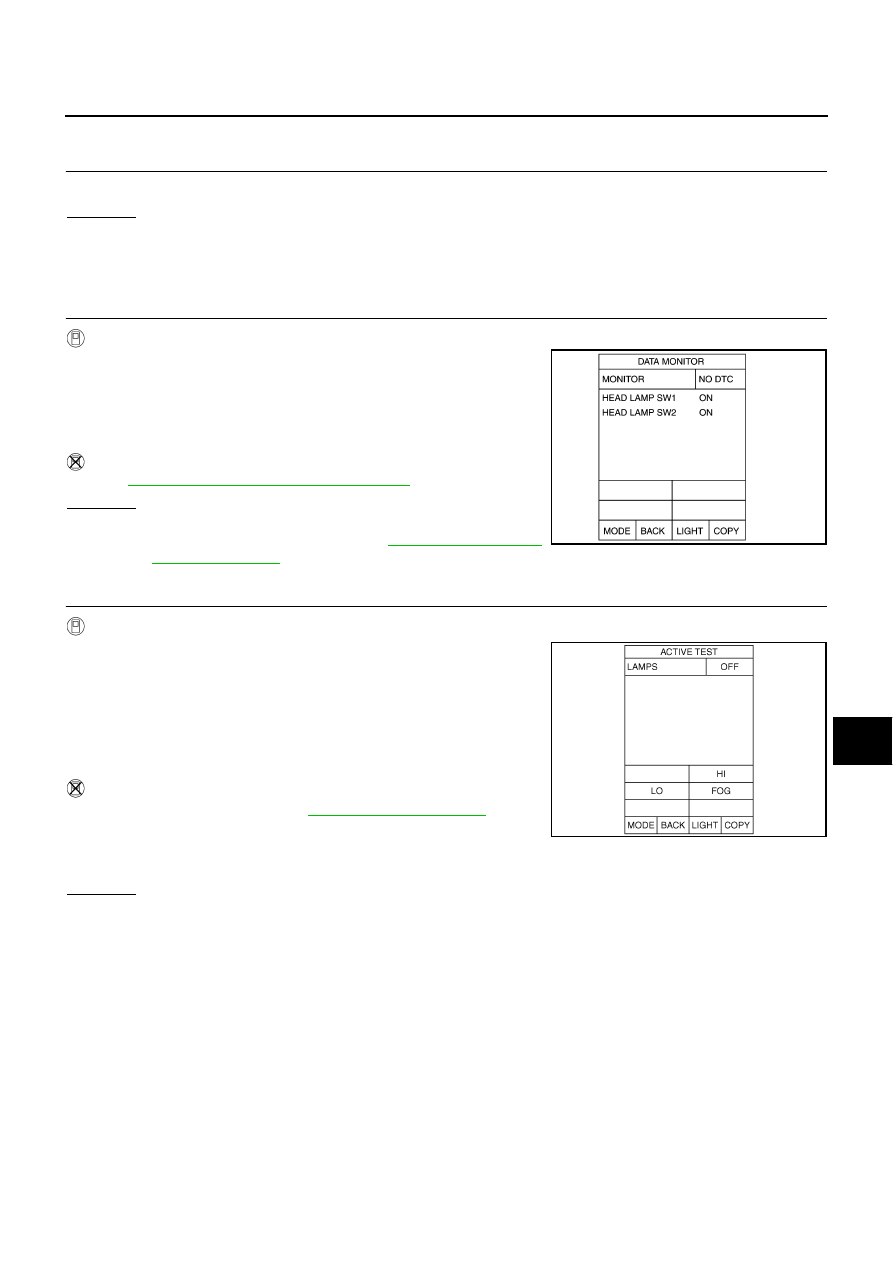

Select “BCM” on CONSULT-II. With “HEAD LAMP” data monitor,

make sure “HEAD LAMP SW 1” and “HEAD LAMP SW 2” turns ON-

OFF linked with operation of lighting switch.

Without CONSULT-II

Refer to

LT-140, "Combination Switch Inspection"

OK or NG

OK

>> GO TO 2.

NG

>> Check lighting switch. Refer to

2.

HEADLAMP ACTIVE TEST

With CONSULT-II

1.

Select “IPDM E/R” on CONSULT-II, and select “ACTIVE TEST”

on “SELECT DIAG MODE” screen.

2.

Select “LAMPS” on “SELECT TEST” ITEM screen.

3.

Touch “LO” screen.

4.

Make sure headlamp low beam operates.

Without CONSULT-II

1.

Start auto active test. Refer to

.

2.

Make sure headlamp low beam operates.

OK or NG

OK

>> GO TO 3.

NG

>> GO TO 4.

When lighting switch is 2ND

position

: HEAD LAMP SW 1 ON

: HEAD LAMP SW 2 ON

PKIA6325E

Headlamp low beam should operate.

Headlamp low beam should operate.

SKIA5774E