Nissan Murano Z50 (2003 year). Manual - part 136

COIL SPRING AND STRUT

FSU-9

C

D

F

G

H

I

J

K

L

M

A

B

FSU

Revision; 2004 April

2003 Murano

COIL SPRING AND STRUT

PFP:55302

Removal and Installation

AES000NM

REMOVAL

1.

Remove tire with power tool.

2.

Remove cowl top grille. Refer to

3.

Remove brake caliper with power tool. Hang it in a place where it will not interfere with work. Refer to

28, "Removal and Installation of Brake Caliper Assembly"

.

4.

Remove lock plate of brake hose from strut assembly.

5.

Remove harness of wheel sensor from strut assembly. Refer to

.

NOTE:

Do not pull on wheel sensor harness.

6.

Remove mounting nut between strut assembly and connecting rod.

7.

Remove mounting bolt and nut between strut assembly and steering knuckle with power tool.

8.

Remove mounting nuts on mounting insulator bracket with power tool, then remove strut assembly from

vehicle.

INSTALLATION

●

Refer to

for tightening torque. Install in the reverse order of removal.

NOTE:

Refer to component parts location and do not reuse non-reusable parts.

●

Perform final tightening of strut assembly lower side (rubber bushing) under unladen conditions with tires

on level ground. Check wheel alignment. Refer to

FSU-16, "SERVICE DATA AND SPECIFICATIONS

Disassembly and Assembly

AES000NN

DISASSEMBLY

NOTE:

Make sure piston rod on strut is not damaged when removing components from strut assembly.

1.

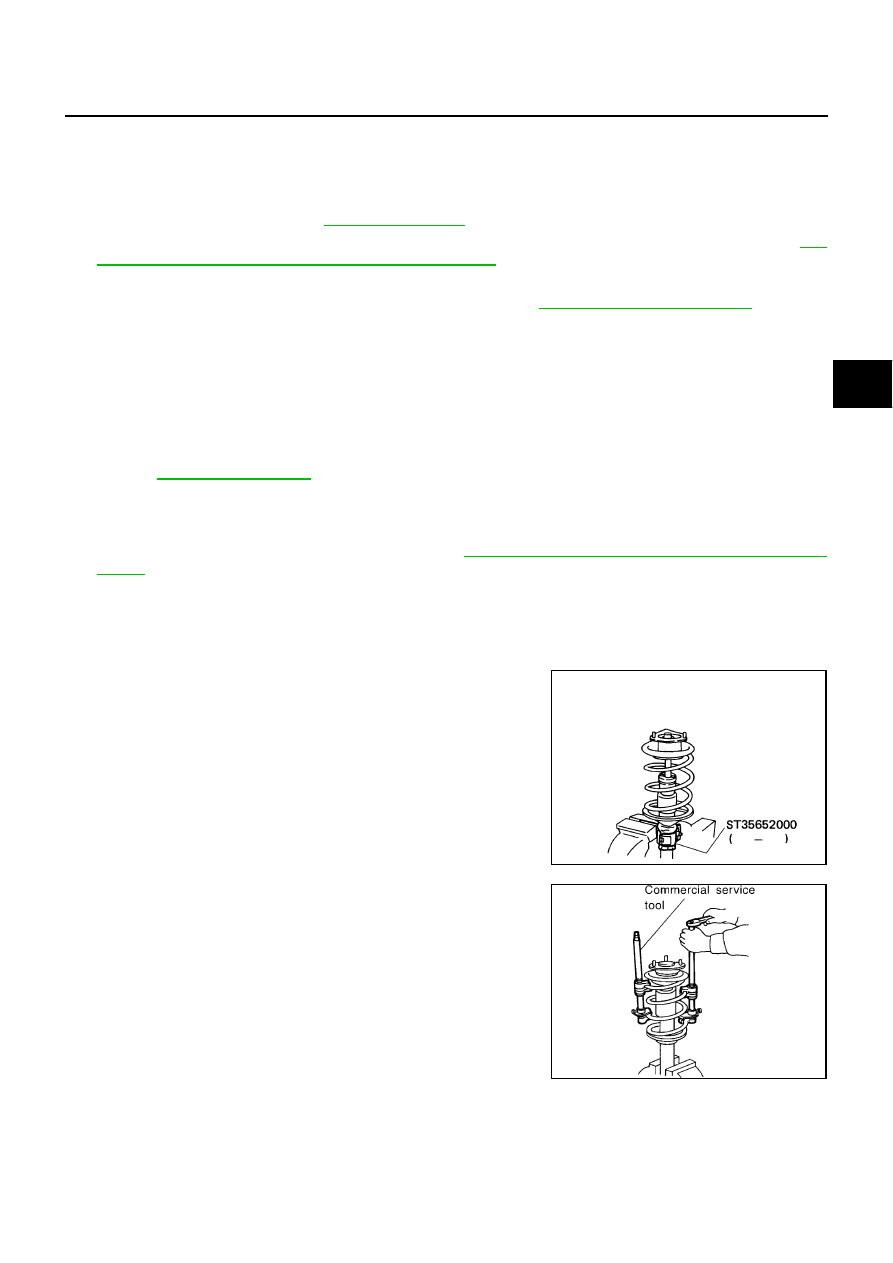

Install strut attachment (SST) to strut and fix it in a vise.

CAUTION:

When installing strut attachment (SST) to strut, wrap a shop

cloth around strut to protect it from damage.

2.

Using a spring compressor (commercial service tool), compress

coil spring between spring upper seat and spring lower seat (on

strut) until coil spring is free.

CAUTION:

Be sure spring compressor (commercial service tool) is

securely attached to coil spring. Compress coil spring.

SEIA0296E

SEIA0297E