Nissan Murano Z50 (2003 year). Manual - part 135

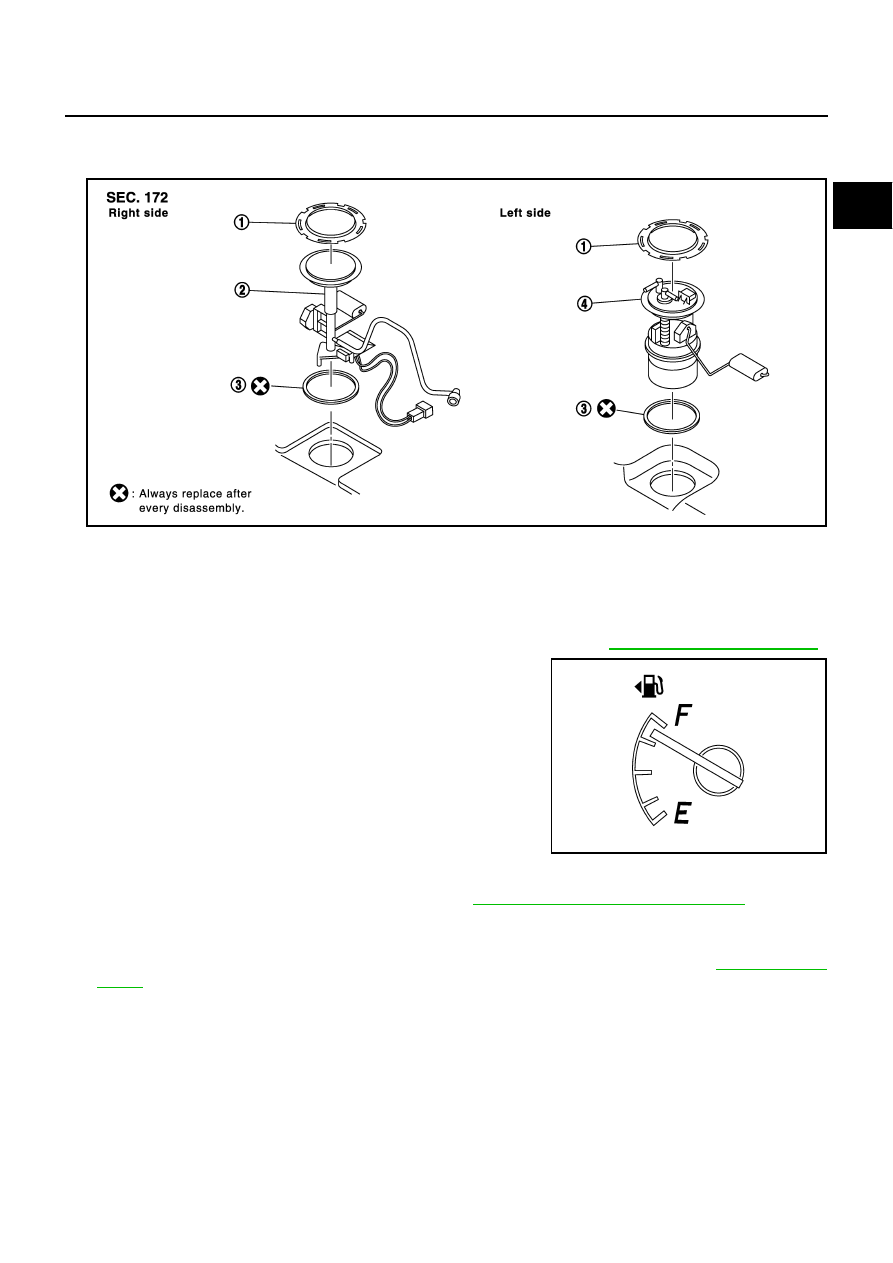

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-5

C

D

E

F

G

H

I

J

K

L

M

A

FL

Revision; 2004 April

2003 Murano

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

PFP:17042

Removal and Installation

ABS005ZC

REMOVAL

WARNING:

Read “General Precautions” before working on the fuel system. Refer to

1.

Check fuel level on level place. If gauge indicates more than the

level shown in figure (full or almost full), drain fuel from fuel tank

until gauge indicates level shown in figure or below.

●

In case fuel pump does not operate, take following procedure.

a.

Insert fuel tube of less than 25 mm (0.98 in) in diameter into fuel

filler tube through fuel filler opening to draw fuel from fuel filler

tube.

b.

Disconnect fuel filler hose from fuel filler tube.

c.

Insert fuel tube into fuel tank through fuel filler hose to draw fuel

from fuel tank.

●

As a guide, fuel level becomes the position shown in figure or

below when approximately 20 liter (5-1/4 US gal, 4-3/8 Imp gal) of fuel are drained from fuel tank.

2.

Release the fuel pressure from the fuel lines. Refer to

EC-66, "FUEL PRESSURE RELEASE"

3.

Open the fuel filler lid.

4.

Open the filler cap and release the pressure inside the fuel tank.

5.

Remove the rear seat cushion trim and pad bolts, then lift up rear seat cushion. Refer to

1.

Retainer

2.

Sub fuel level sensor unit

3.

O-ring

4.

Main fuel level sensor unit, fuel filter

and fuel pump assembly

SBIA0392E

SBIA0393E