Nissan Murano Z50 (2003 year). Manual - part 95

DTC P0133, P0153 HO2S1

EC-239

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision; 2004 April

2003 Murano

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

Diagnostic Procedure

ABS004E1

1.

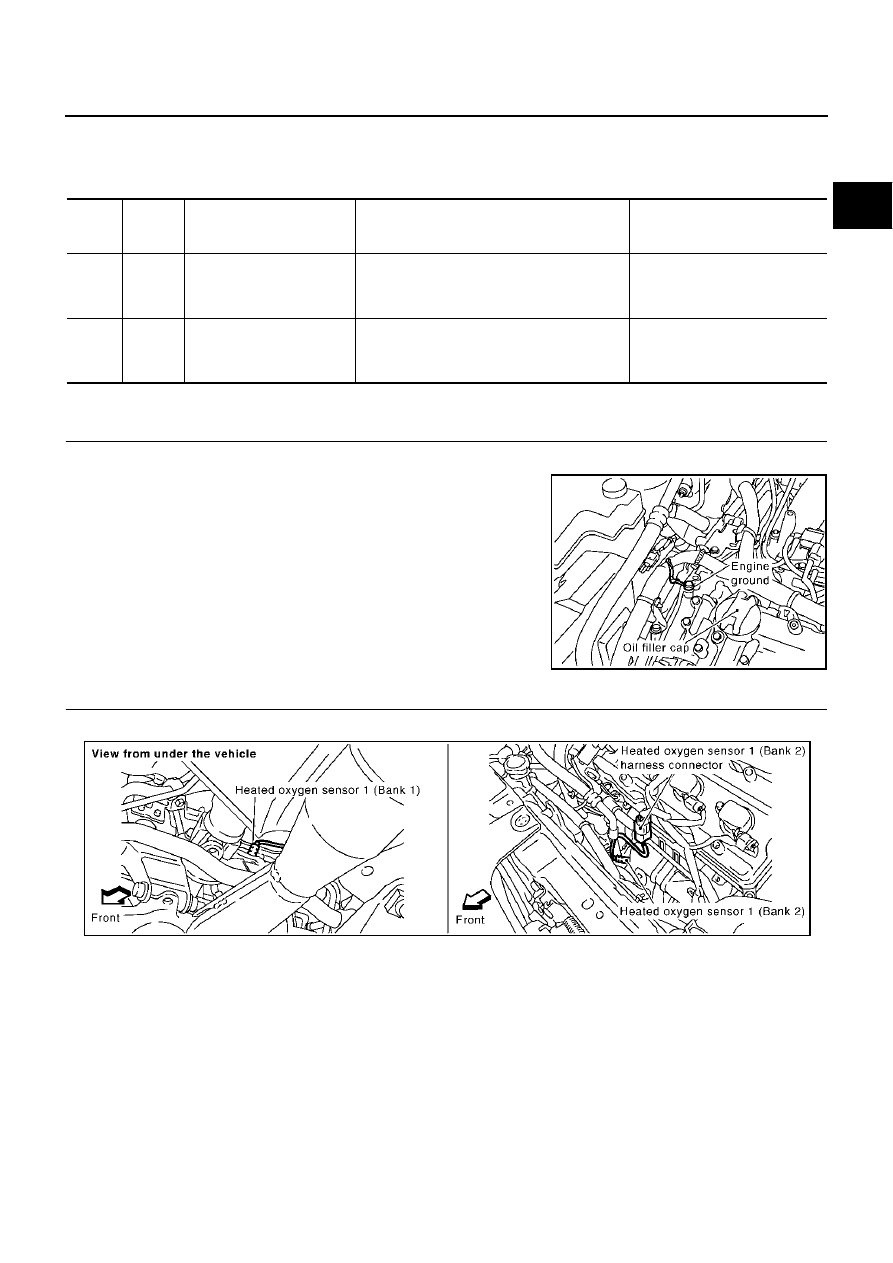

RETIGHTEN GROUND SCREWS

1.

Turn ignition switch “OFF”.

2.

Loosen and retighten engine ground screws.

>> GO TO 2.

2.

RETIGHTEN HEATED OXYGEN SENSOR 1

Loosen and retighten heated oxygen sensor 1.

>> GO TO 3.

TER-

MINAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

16

LG

Heated oxygen sensor 1

(bank 2)

[Engine is running]

●

Warm-up condition

●

Engine speed is 2,000 rpm.

0 - Approximately 1.0V

(Periodically change)

78

B

Sensors' ground

(Heated oxygen sensor)

[Engine is running]

●

Warm-up condition

●

Idle speed

Approximately 0V

PBIB1298E

Tightening torque: 40 - 50 N·m (4.1 - 5.1 kg-m, 30 - 37 ft-lb)

PBIB1301E